Ground-based astronomy

TNO develops technologies for ground-based astronomy to help mankind better understand our place in the universe. TNO is a world-class leader in ultra-precision opto-mechatronics. We enable cutting-edge technology with our scientific instrumentation development programs. For ground-based astronomy, these include deformable mirrors, laser projection systems and nanometer-precision telescope support structures.

Specialization

Our organization has a 100% success rate in reliable and stable scientific instrumentation. An effective telescope system must have the highest precision components possible to see deeper into the universe, enabling new scientific discoveries. From a system perspective this includes key instruments to maintain, measure and correct the telescope’s vision (optical wavefront). TNO has technology developments that help to do this in the following areas:

- Deformable mirrors (NASA-IRTF-ASM, UH88-ASM, ESA Laser Communications)

- Laser guide star projection systems (VLT, ELT)

- Nanometer precision mirror support structures (ELT)

Deformable Mirrors

Deformable mirrors are a core technology of “Adaptive Optics” used in telescopes to correct for atmospheric turbulence which distorts the view of the telescope (wavefront), to allow ground-based telescopes to see as well as space-based telescopes such as the Hubble Space Telescope and James Webb Space Telescope. TNO has developed an innovative, cutting-edge deformable mirror technology which has the potential to expand how mankind sees the universe.

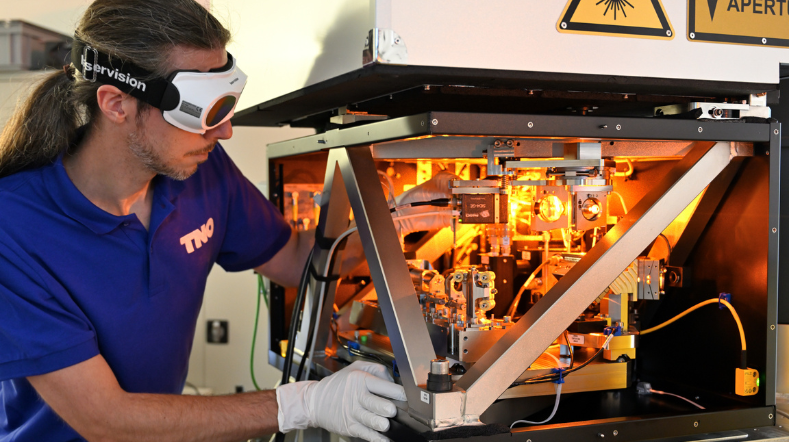

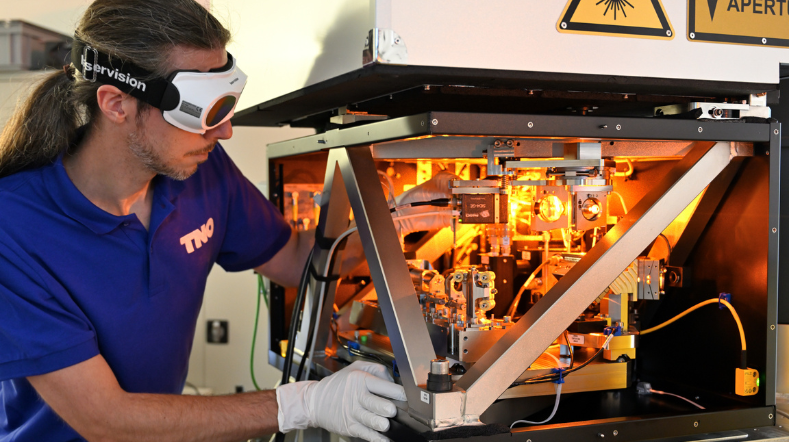

In February of 2024, TNO delivered a new Adaptive Secondary Mirror (ASM) for the NASA-IRTF Telescope in Hawaii (photo above). TNO will deliver an ASM for the University of Hawaii 88-inch telescope later in 2024, and is working on designs for ASMs for the W. M. Keck Observatory, Automated Planet Finder, and Gemini North telescopes.

Of course, adaptive optics requires more than just deformable mirrors. Other key components, such as wavefront sensors, laser guide stars and optimized real-time control systems (as shown below) are key to quality scientific data from large telescopes.

Laser projection systems

Laser projection systems create artificial guidestars at the edge of earth’s atmosphere to act as a beacon (for a wavefront sensor), to measure the optical distortion created by the atmosphere, so that it can be compensated by the deformable mirror (see diagram).

VLT-4LGSF Laser Launch System: improving telescope vision with artificial guide stars

TNO designed, built and delivered the best laser launch telescopes in the world for the for ESO, which have performed flawlessly since 2016.

Extremely Large Telescope Laser Projection System

Based on the VLT heritage, TNO joined with partner Demcon to design and build the laser projection system for the future ELT, which will be the largest optical+IR telescope ever built. To improve the design for reliability and ease of maintenance, TNO has optimized on the design of the VLT laser launch telescopes, and Demcon has succeeded to improve on ESO's laser Beam Conditioning and Diagnostics System (BCDS).

With the help of TNO’s laser guide star launch telescope technology, the Extremely Large Telescope (ELT) will provide insight into some of the greatest astronomical questions of our time, from the birth of stars to the search for signs of life on exoplanets in other star systems.

ELT MT support structure

With its partners VDL and NOVA, TNO successfully completed the design for the Primary Mirror (M1) support structure for ESO's Extremely Large Telescope (ELT). The development, from idea to a fully tested system, took place from 2005-2018. The design met the demanding 25-30 nanometer surface form correction in all gravitational vectors. The 39-meter primary mirror is made of 798 1.4-meter segments, with 133 different mirror shapes, for which the single TNO design can be adjusted to compensate. In collaboration with TNO, VDL was awarded the contract to build the full series of M1 support structures, which project is nearly complete as of April 2024.

Nanometer precision mirror support structures

The newest class of telescopes under development are called Extremely Large Telescopes (ELTs) These include the ESO-ELT (European), TMT and GMT (American led, international consortia). In order to collect more light and see more objects in greater detail, they have primary mirrors ranging from 24 to 39 meters in diameter. A single mirror cannot support is own weight at this size, so they must be made of several mirrors perfectly shaped and aligned to work together. One way to do this is with hexagonally shaped “Segmented Mirrors” as used by ELT and TMT.

Even before the first deformable mirror, the primary mirrors must maintain near-perfect surface form to preserve the quality of the incoming light (and maintain the diffraction limit). Beyond excellent component design and production, this includes calibration and actuation to counter natural forces including gravity (due to changing telescope orientation), wind loading, thermal gradients and ground movement.

Decades of heritage with 100% reliability

Since 1964 TNO has designed, built and calibrated a growing list of mainly optical instruments and modules for space and scientific instrumentation. Starting with the very first scientific instrument built for ESA, TNO has a proven track record in space instruments and components spanning over half a century. TNO has consistently delivered breakthrough technology and components, ranging from spectrometers for earth observation and planetary exploration to high-tech, mission-critical space components. Other astronomy applications currently running include the delay lines and star separators for the VLT, the world's largest optical interferometric telescope system.

TNO combines four areas of expertise to reach cutting-edge levels of accuracy and control in ultra-precision opto-mechatronics:

- Optics (optical design and engineering)

- Mechatronics (mechanical design, mechanisms and controls to full optical systems)

- Space systems engineering (engineering, managing and testing the finest details to ensure performance in the most challenging environments)

- Optics manufacturing (nanometer precision of complex optics, coatings, freeforms and aspheres).

With over 60 years of space heritage, we develop one-off and prototype instrumentation for earth observation, space-borne science missions, terrestrial astronomy and big science solutions, extended with our recent development for high-bandwidth laser satellite communication.

We look forward to working together with you to design and build the most demanding, highest quality scientific instrumentation.

Get inspired

TNO to design adaptive secondary mirror for Keck Observatory

Sentinel-5: ultra-precise satellite data for a healthier future

Optics

Time setter story: Max van Strien

TNO technology selected for Secondary Mirror of W. M. Keck Observatory