New paper: Digitisation crucial for circular industry

By 2050, the Netherlands aims to have transitioned to a sustainable society with a carbon-neutral circular industry. Smaller and flexible factories will operate in close proximity to the consumer. New business models will mean that products are leased rather than sold to customers and taken back after use. This transition calls for the reorganisation and adaptation of industrial processes and adoption of new technology. In Digitisation crucial for circular industry, a paper published today in Dutch, TNO explains how and why the use of data is essential to this transition.

Use of data is key to achieving full circularity by 2050. The paper outlines a timeline for the Netherlands.

Start your journey today

and help build a circular industry by 2050

“Now is the time to take action to work towards maximum reuse of materials, minimisation of waste, carbon-neutral production and generation of sustainable renewable energy. Digitisation is essential to monitor the use, loss and condition of the materials used throughout the production chain.”

Digital transformation throughout in the chain will lead to a circular industry

To successfully transition to a sustainable ecosystem of smart digital factories and smart chains, all parties in the chain have to participate and adopt the same standards. Start digitising your processes today and discuss digital transformation with your suppliers and customers. The more companies throughout the chain adopt this approach, the sooner all players will speak the same language and operate digitally.

Achieving full circular industry is essentially a Digitisation challenge

Data can be fed into robots and used to create automated workstations and flexible production systems. This is the basis of the digital factory. The pandemic has underscored the importance of resources and production chains. Scarcity of raw materials and inevitable climate change make it essential to take action. It’s time to rise to the challenge of digital transformation.

An example of what circular industry will look like in 2050

Manufacturers will build sustainable cars equipped with sensors that send the manufacturer real-time data about the status of each part and its use. Small parts will be manufactured on demand by specialised 3D print shops. Larger parts will be supplied by the refurbishment facility in your region. If too many parts of your car have reached the end of their service life, the manufacturer will deliver a new one to you. Your old car will be fully recycled at the factory.

Let yourself be inspirered

Scale up: manufacturing throughput and quality

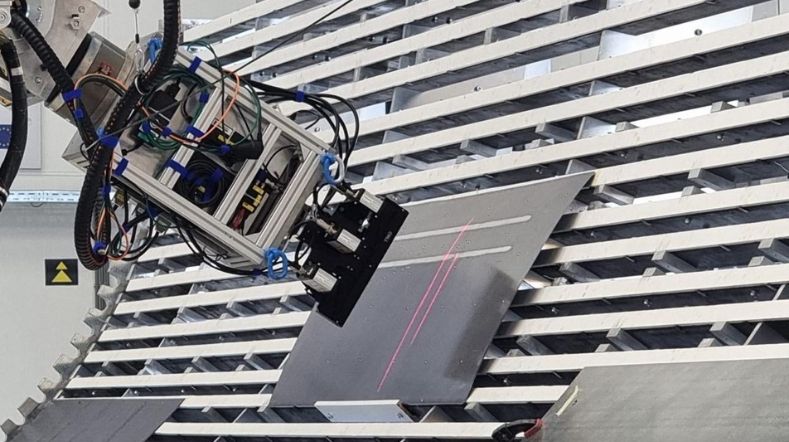

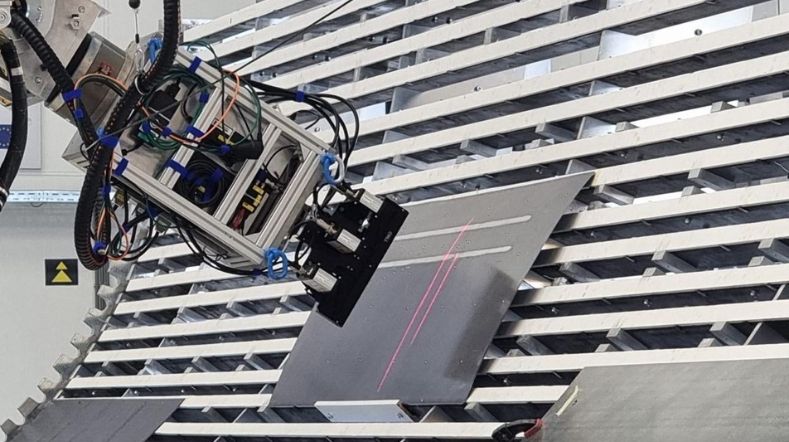

Non-destructive inspection

Strategic autonomy: digitalization & value chain integration

Productivity: manufacturing variability

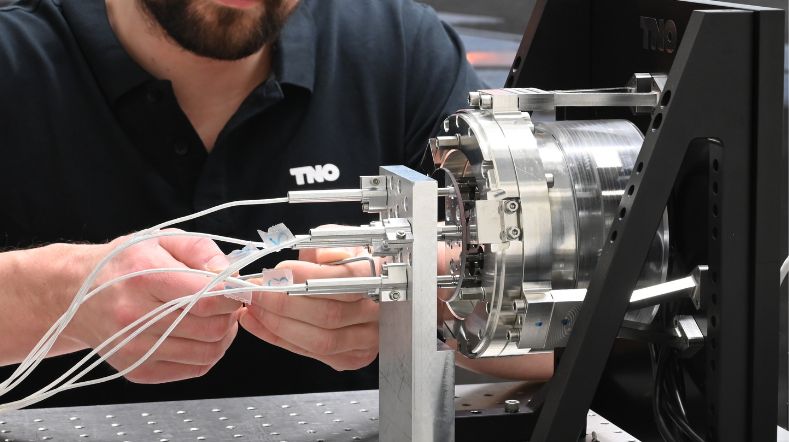

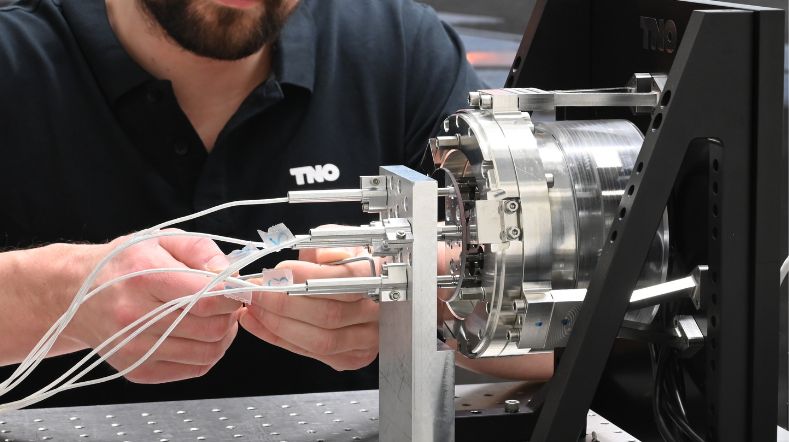

Optomechatronics