Heat transfer and fluid dynamics

To sustain growth and prosperity, societies around the world require energy. Energy that needs to be produced, transported and dispatched with clean, efficient, safe, reliable, flexible and affordable systems. The TNO experts of Heat Transfer and Fluid Dynamics provide innovative solutions to meet this challenge based on expertise in fluid dynamics, mechanical engineering, measurement techniques, sensor development, data analytics and artificial intelligence.

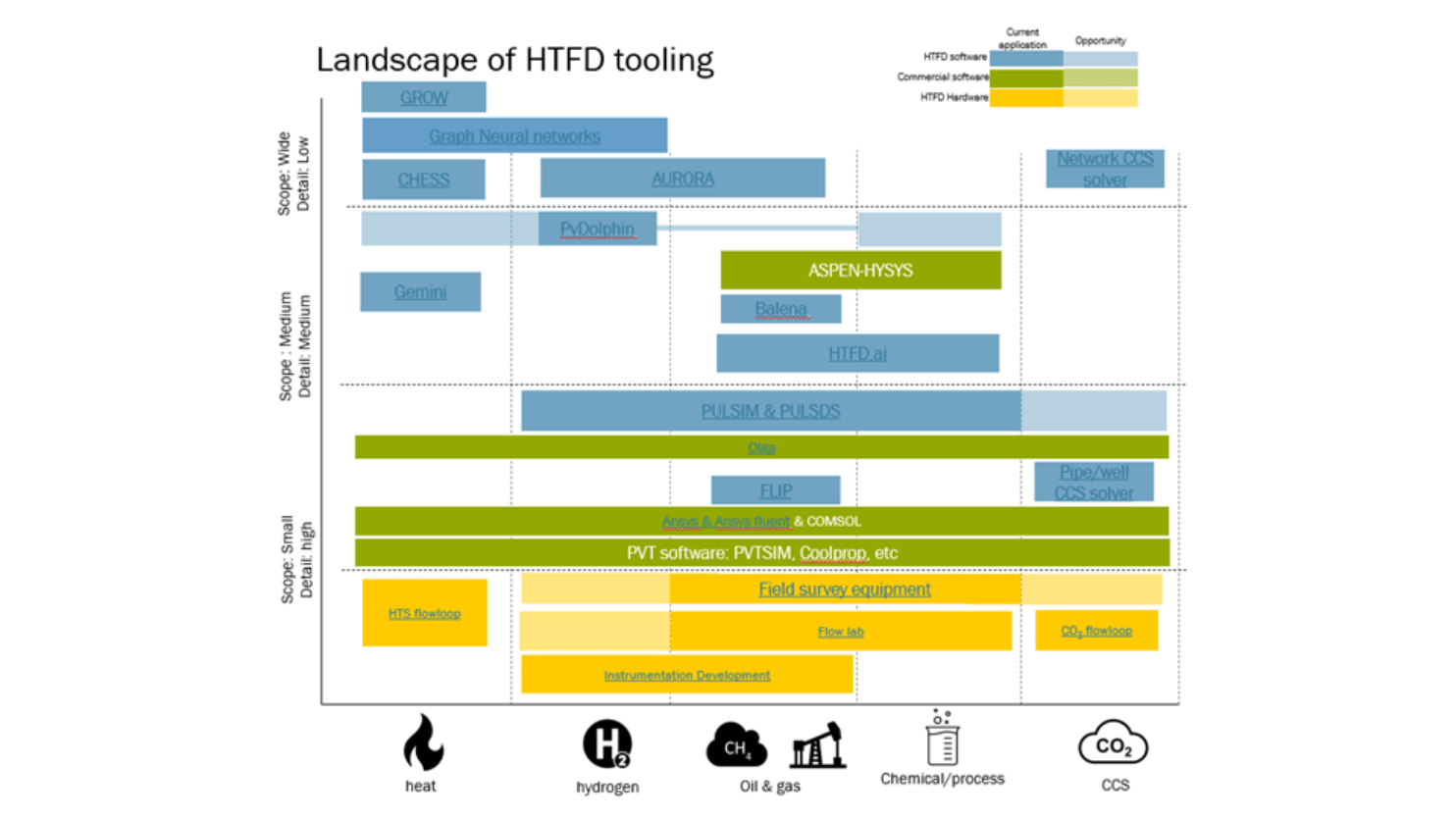

Our expertise can be divided in four technology areas:

-

Pulsation, vibration & noise, where we optimise the design of process systems from an integrity perspective leading to increased safety and reliability, for domains such as the petrochemical industry, hydrogen and CO2 transport.

-

Flow modelling, where we analyse and optimise energy production and transport efficiency for domains such as traditional hydrocarbons, geothermal energy, electrochemistry, and CO2 transport.

-

Energy system modelling, where we model, monitor and optimise current and future energy infrastructure’s efficiency and flexibility based on physical models, big data, sensors and optimization.

-

Artificial intelligence and digitalization, where we combine our expertise on physics and fluid dynamics with state of the art data analytics and artificial intelligence to deliver digital solutions for various domains within the energy & materials transition.

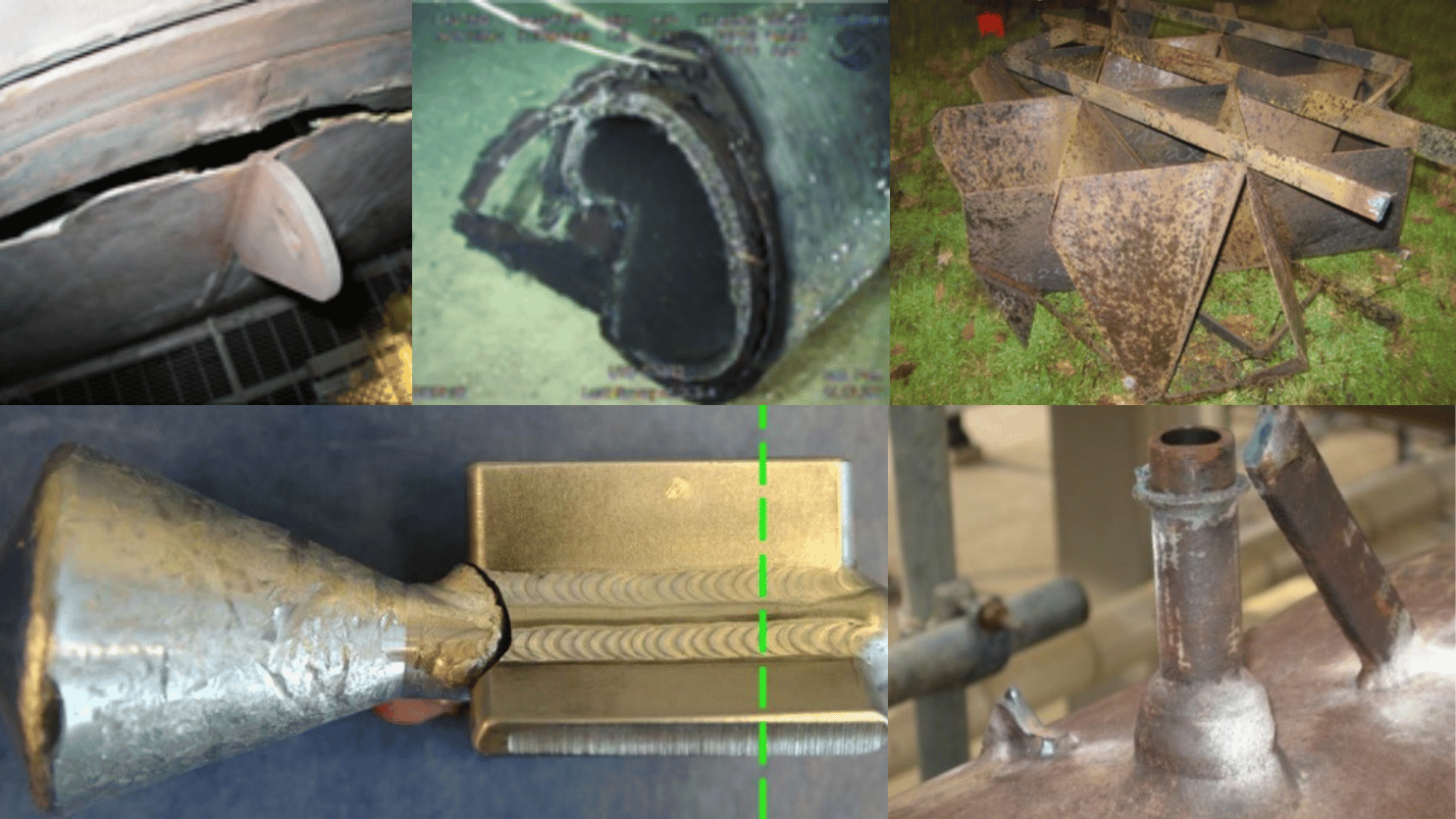

Pulsation, vibration and noise

What is our purpose?

We contribute to safer and more productive facilities with our world-leading expertise (as judged by a panel of independent industry-leading experts) on pulsations, vibrations and noise.

Rotating proces equipment, (compressors and pumps) deliver flow in a pulsating fashion. The same applies in multiphase systems: an mixture of solids and/or liquid and/or gas flows through the pipework at ever changing fractions of each component. These fluctuations in fluid density, velocity or pressure are present throughout the system and all the time, which may cause excessive noise, vibrations, disruption of instrumentation or eventually even failure.

For whom are we doing what?

With our models, lab test facilities and field measurement capabilities we support energy operators, OEM, end users, regulators and governments in domains such as the petrochemical industry, hydrogen and CO2 transport.

Our USPs

TNO contributes to safer and more productive facilities with its world-leading expertise (as judged by a panel of independent industry-leading experts). Decades of research into the underlying physics of flow instabilities allows us to better model and predict the magnitude of the excitation sources.

- Access to our pulsation simulator PULSIM™ enables us to understand the propagation of pressure pulsations and dynamic loads applied on the piping.

- In cases with peculiar geometries or otherwise for research purposes, TNO’s labs are available for scaled testing.

- Finally, in existing assets, TNO’s field measurement team can be mobilized to analyse on site the status of the system.

With its combination of scientific depth, software development and licensing, laboratories and practical experience in the field, TNO is uniquely positioned to maximize the productivity of energy and process systems while safeguarding their integrity.

Recent projects and tool developments

- Pulsim

- EFRC website

- Pulsation and vibration analyses

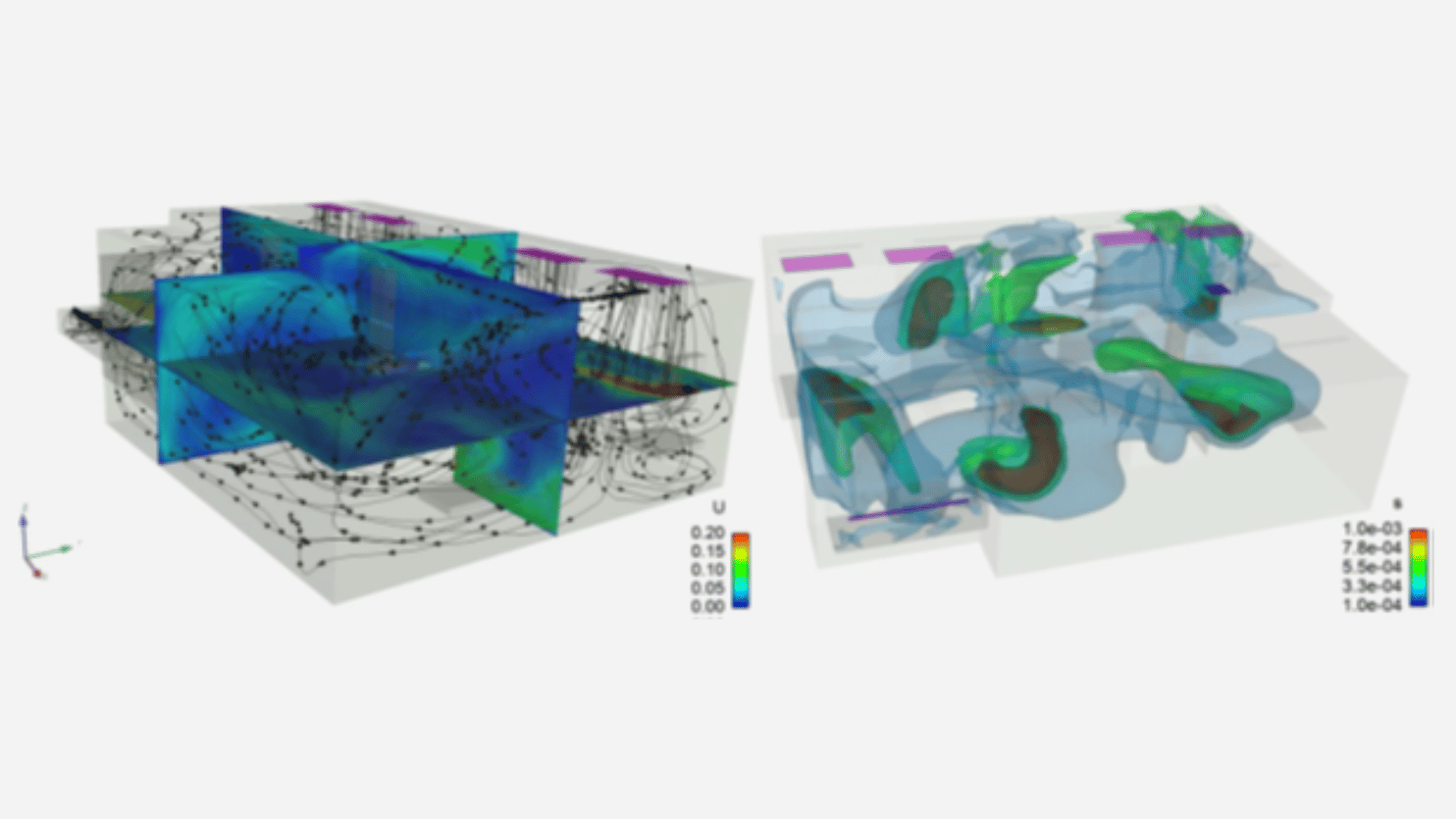

Flow modelling

What is our purpose?

We use high-fidelity flow modelling expertise to contribute to the Energy & Material Transition. This team has the expertise and the tools (in-house developed or commercial) to address the challenges in the new era of sustainable development, with experts in the field of Electrochemistry, Geothermal, CO2 transport, and Oil & Gas to cover the whole value chain of fluid flow related topics.

For whom are we doing what?

Accurate fluid flow simulations are a must in several stages of the lifecycle of many products, whether it is a wind turbine blade design, a corrugated pipe for gas transport or an air quality assessment in a building. A fit-for-purpose tool can improve design, operation and maintenance stages, reducing costs and risks and improving robustness and know-how.

With our models and experimental set-ups, we support energy operators, OEM, end users, regulators and governments with the following:

- Production, consumption and transport, electrolyzer and fuel cell multiphase modelling for the hydrogen industry.

- Hydrogen transport and safety, natural gas admixing, dispersion and ignition.

- Simulations in environments where no visual information is available and where heat transfer and Joule-Thompson effects play a major role, such as with CO2 processes.

- Non-intrusive modelling and analysis, where topics such as ESP environment, erosion, rotor and injection dynamics for Geothermal energy.

- In the era of digitalization, Artificial Intelligence can be combined with CFD and sensor data to enhance predictions and act proactively.

- Using High-Temperature high-Salinity flowloop (HTS) to provide state of the art experimental insights for geothermal and heat network related challenges.

Our USPs

Our customers return to TNO for our:

- Computational Fluid Dynamics (CFD) capabilities which has an added value as a standalone simulation technique and as a support to experiments, for investigation, correlation, and validation cycles.

- Efficient high fidelity simulations for design optimization, risk assessment and radically new concepts.

- Experimental set-ups for a better insight into the fluid flow in CO2, geothermal, and heat networks applications.

The size and aggregation of the models we use depends heavily on the scope of the research questions, and can range from local networks in asset premises, to DSO and TSO networks on international scale.

Recent projects and tool developments

-

Action

-

Porthos

-

NextGen

-

DRAGLOW

-

PERFORM

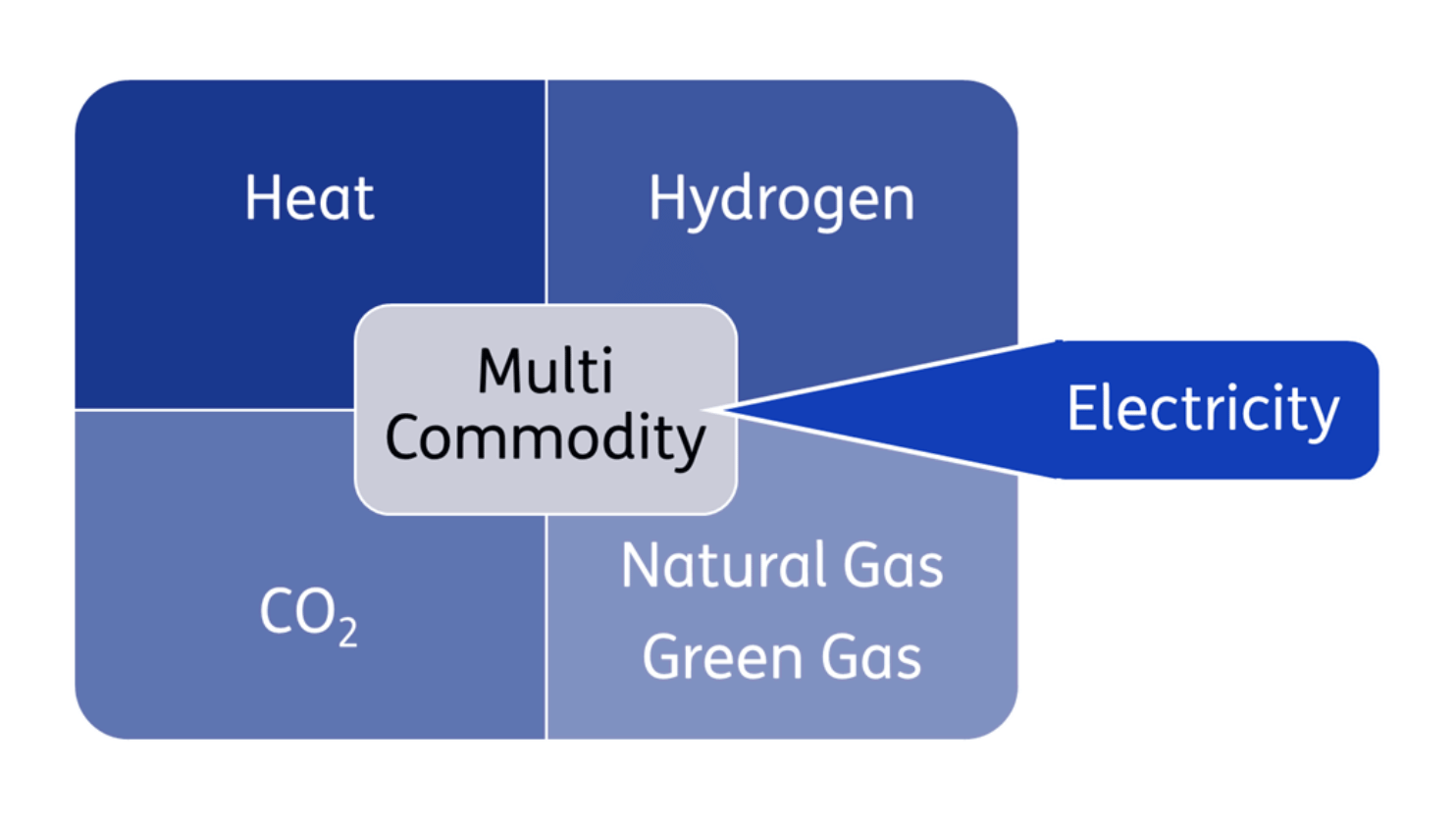

Energy system modelling

What is our purpose?

We facilitate the transition to integrated energy grids and assets by orchestrating the system integration of multi-commodities (electricity, gasses (NG, hydrogen, biogas), heat). In addition, we enable the switch to the complex future gas grid that results from the changing supply and demand of gas and the adaptation to new gasses (hydrogen, biogas, admixing, ammonia), through numerical modelling, as well as dedicated sensor development to support these transitions.

For whom are we doing what?

With our models, we support national and international DSOs & TSOs (and energy retailers), regulators and governments, as well as energy operators and end users with the following:

- Model interactions between the different grids (electricity, gasses & heat).

- Identify of bottlenecks in the future grid and suggest possible solutions, risk assessment of design and operations (security of supply, which area is critical, need to be reinforced etc.)

- Provide system planning (coordination across E,G & heat) and infrastructure investment timing advice, for new infrastructure, extensions and re-use.

- Provide new innovative digital solutions / prototyping / Forecasting & Prediction & Operations.

- Dynamic modelling and optimization of multi-commodity energy assets (e.g., wind farm + electrolyzer + industrial consumer), techno-economics integration.

Our USPs

Our customers return to TNO for our:

- Knowledge on dynamic physical simulation of heat and gas grids and grid interactions between electricity, gasses & heat.

- (Offshore) Hydrogen transport knowledge, concerning blending/deblending and pure hydrogen streams from producer to consumer, including storage, import and parties in the hydrogen value chain.

- End-to-end (supply to demand) modelling including physical modelling of the asset (‘the nodes’).

- Validated gas grid solvers (simulation tool).

- Multi disciplinary project coordination.

- Independent assessment.

- Looking beyond daily operations.

Recent projects and tool developments

More information about our frequently used tools:

-

Aurora

-

MCGS

-

PyDolphin

-

Chess (design toolkit?)

-

Grow

-

HY3+

-

North Sea Energy Program

-

HyDelta

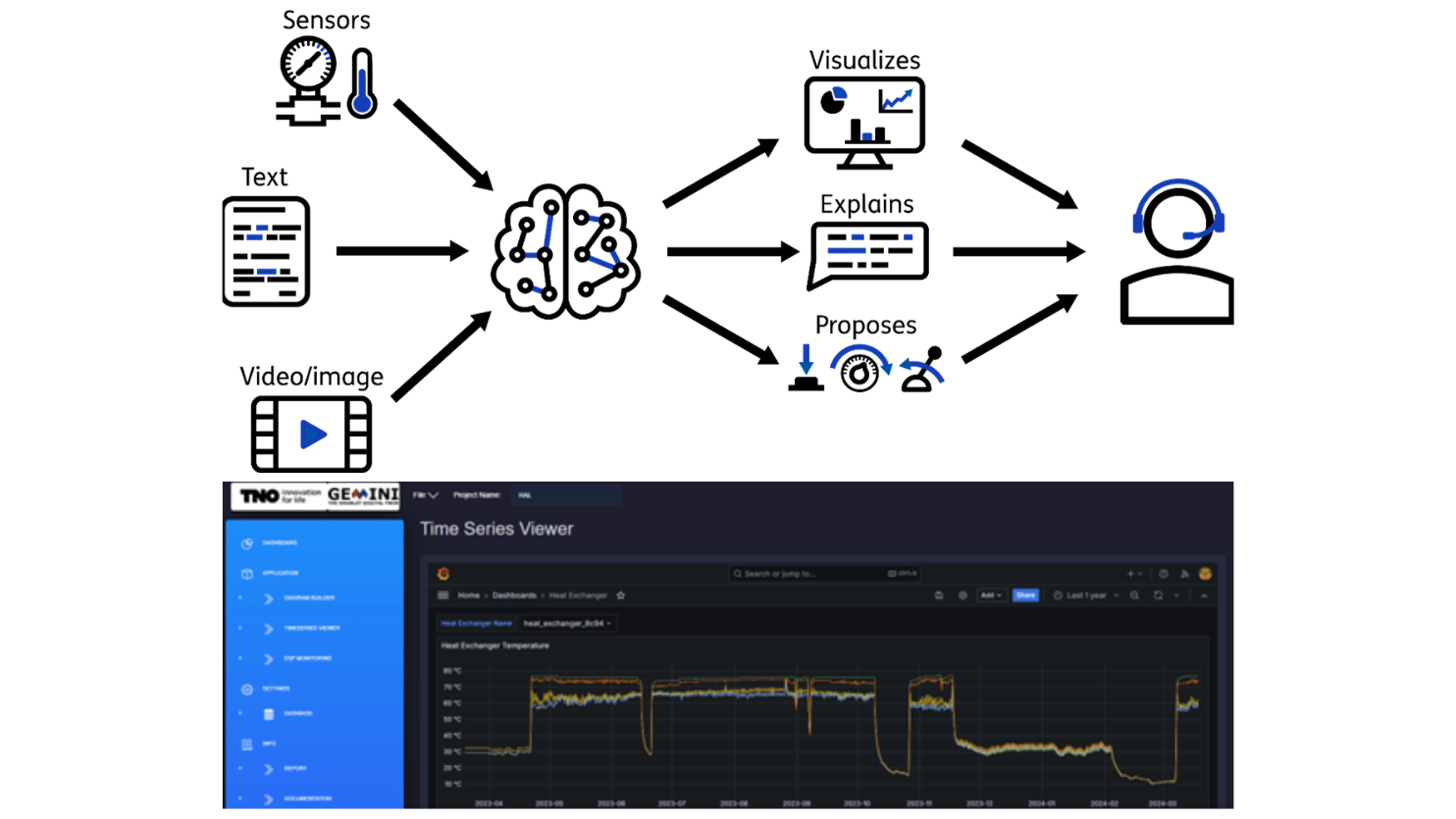

Artificial intelligence and digitalization

What is our purpose?

The ongoing energy and materials transition is leading to increasingly more complex and dynamic production and operation processes in energy systems and industrial processes. Decarbonization of these sectors drives them to maximize the use of sustainable feedstocks and integrate even closer with the renewable electricity grid, complicating the associated processes even further.

Here, an opportunity lies in the every growing availability of data in a variety of forms, be it time-series data from sensors, text data from design and operational reports, or images and video footage of the equipment in these systems. All sources of valuable information that can help engineers and operators make better decisions on the design and operation of their plants and processes. The main goal of the AI and Digitalization team is to develop novel digital technologies empowered by AI to extract the value from this data and help our partners and clients:

- Gain insights into their processes and identify potential issues

- Operate their systems consistently and efficiently

- Optimize the design of energy assets and industrial processes

- Transfer knowledge and experiences from existing plants to future plants and processes

- Speed up the learning curve associated with the energy and materials transition

- Real-time monitoring system through digital twin to enhance operational efficiency and decision supports

List of technologies

Within the AI and Digitalization team we are working on developing a variety of technologies and tools, including:

- Digital Twin Technologies

- State-of-the-art machine learning and deep learning algorithms such as:

- Graph Neural Networks for energy grids

- Advanced process control (including Reinforcement learning) for optimal control of energy systems and process installations

- Physics-informed neural networks

- Hybrid AI models for energy production forecasting under uncertainties

- Real-time automated event detection

- Virtual sensors and metering

- Modelling of molecular properties and generative design

- TOPOS Novel workflows for optimizing the type, number, and location of sensors in various sectors

- ChatGeoPT: Domain-respected large language models (LLMs) to analyze large set of text data

- Federated Transfer Learning: A novel technology to learn from different data sources of various stakeholders without a need to share data

- Azure cloud web-based applications

For whom are we doing this?

Optimizing design and operational (up to real-time) decisions for energy and industrial processes operators and engineers. Throughout the years, we have helped our partners and clients develop:

- Dynamic data-driven modelling and AI optimization workflows for energy systems

- Real-time event detection algorithms to support root-cause failure analysis

- Virtual and soft-sensing methods for real-time model-based monitoring of energy assets

These technologies have been demonstrated in many sectors, including E&P, geothermal systems, energy grids and assets, and chemical and process plants.

Our USPs

Within our team, we tackle problems by starting from the domain first. By using our backgrounds in physics and engineering and years of experience in the process and energy industries, we can: identify for which challenges AI and digitalization can provide the biggest benefits, highlight what data is most insightful for use in AI solutions, and develop and implement these solutions in a trusted and reliable manner. Our team's expertise lies in the following topics:

- Combining our skills in creating physical or data-driven models and knowing how to deploy them in digital twins or web-based applications.

- Integration of domain knowledge with AI technologies.

- AI methods to process and learn from ‘small’ data.

Broad field of expertise

For over 50 years, TNO has developed expertise in fluid flow in energy production systems, transport systems and processing plants. Our experts use physical and mathematical models to maximize the reliability and efficiency of production processes. In addition to modelling, we benefit from extensive laboratory facilities to analyse and evaluate the performance of new concepts and validate the accuracy of models. We also employ our measurement expertise outside the lab, to analyse the performance of process systems in practice both onshore and offshore.

Within these expertise areas we offer dedicated products (e.g. PulsimSuite and operating support systems) and high-end consultancy in the area of trouble shooting and design optimisation. In addition to consultancy, we also undertake dedicated R&D projects in which we apply our expertise to help our clients succeed by developing technology that improves their products or production process. Our high-level knowledge, flexibility and creativity allow us to tackle a wide range of design challenges.

Want to know more?

Read the white paper 'Boosting The Energy Transition'.

Get inspired

TNO and Quobly join forces to advance industrial-scale silicon quantum technology

Balancing skepticism and blind trust: critical thinking as the key to responsible and effective use of GenAI

Making sustainability strategies robust and resilient in an uncertain world

Sunlight-driven technology for sustainable chemistry and solar fuels

ACROSS: Can adaptive camouflage help make soldiers invisible to enemy detection?