Sustainable process and energy systems

The development of new, sustainable technologies and processes is important for people and the environment. The Sustainable process and energy systems expertise group works to develop a sustainable industry, based on broad knowledge and expertise. We do this together with our partners.

Expertise group focus areas

We currently focus on the following focus areas:

- Thermal energy: heat storage and energy conversion into heat and back again.

- Sustainable chemistry: the use of bio-based resources for the production of chemicals and in chemical processes.

- Gas treatment: solutions for the production of renewable gases and the capture and use of CO2.

We develop efficient processes within these areas. We create prototypes and share our knowledge to give partners and customers the competitive edge. For each focus area, we explain our work below.

Thermal energy

Thermal energy is a source of heat. It can provide heat for homes through sustainable energy production, use, and storage. The Sustainable process and energy systems expertise group looks at how thermal energy can be used as an energy source. We work on optimisation and ISO certification and combine this with our knowledge of glazing and insulation. This gives us a picture of the thermal balance in homes and allow us to certify products and estimate their annual performance.

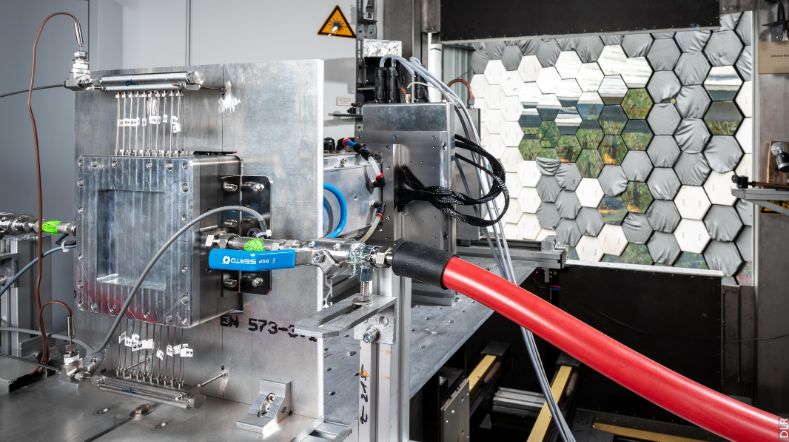

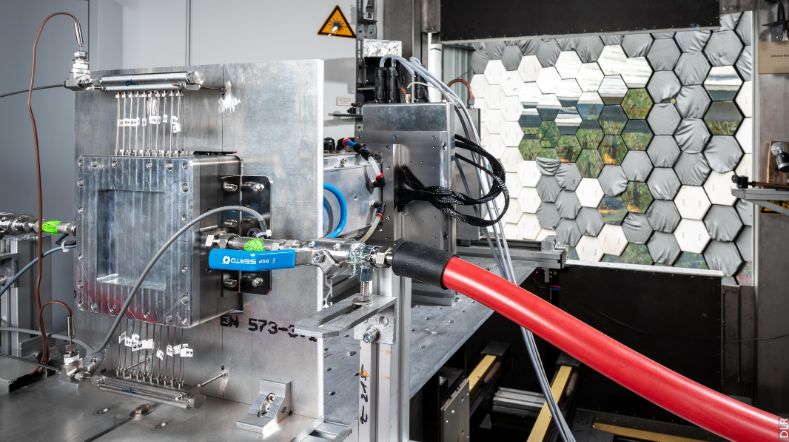

Heat battery and energy conversion

Thermochemical heat storage is particularly attractive for heat batteries. A compact, seasonal heat battery can store excess solar heat in summer for use in winter.

In addition to the heat battery, we are developing new technologies for energy conversion, such as magnetocaloric cooling, in which materials are cooled by switching magnetic fields, for example to room temperature.

Our research expertise in thermal energy focuses on:

- Determination of the optical properties (emission/absorption, transmission, reflection: EN 410 & 673) and thermal transmission (U value: EN-ISO 12567) of materials.

- Evaluation of solar thermal collectors and water heaters (ISO 9806 and ISO 9459).

- Determination of physico-chemical and thermal properties of materials for use in thermal storage and conversion. We use both commercial equipment and equipment developed in-house, including:

- Clausius-Clapeyron (pressure-temperature diagram)

- vacuum thermogravimetric analysis (TGA)

- thermal and vapour cycles of thermochemical material

- Advising on thermochemical materials and equipment, e.g., heat pumps or heat batteries.

- Modelling complete thermal systems with heat generation, storage, and use based on reference data (NEN 7120 and NEN 5060).

- Building and researching demonstrations of thermal energy systems.

Sustainable chemistry

It is very important that the chemical industry pollutes the environment as little as possible. Sustainability and decarbonisation are key challenges in this respect. Less pollution can be achieved by designing new products and processes that use as few hazardous substances as possible. An example is the implementation of 'green chemistry'.

Green chemistry

We are actively involved in green chemistry solutions for the production of industrial chemicals. We focus on the development of chemical production processes of bio-based resources and sustainable processing. We are experts in:

- Development, design, and testing of chemical processes

- Construction of test units on a laboratory scale

- Techno-economic analysis of chemical production at different stages of process development

- Bio-based and organic chemistry

- Electrochemistry, development of electrochemical processes, modelling of electrochemical conversions

- Separation processes

We offer efficient solutions in the implementation of ‘green’ chemical production processes. For example, electrochemical conversion, mainly from biomass, but also from fossil fuels.

Separation technology

In order to produce more efficiently and with higher quality, the number of separation steps must be reduced. This can be done by integrating and intensifying separation processes, thereby reducing energy consumption and costs, and improving quality. That is why TNO focuses on separation processes that have high selectivity and low energy consumption.

New technologies

We focus on three techniques, i.e. crystallisation, extraction, and membrane technology. We are also working on new generations of separation technologies that use external forces, such as centrifugal forces, electric fields, and microwave radiation. We are also working on reactions and separations that use renewable electricity as a driving force instead of heat from fossil fuels.

Gas treatment

To work towards a cleaner industry, we are developing technology for gas capture and treatment. We develop solutions with economic, environmental, and technical advantages over existing gas processing plants. For example, for carbon capture and biogas treatment.

Leading position

TNO has a leading position in the Netherlands in advising on and creating solutions for the recovery, recycling, and reuse of gas sources containing harmful gas. We support the complex large-scale implementation of carbon capture, transport, and storage (CCS) by advising companies and governments on technological, economic, and safety aspects.

Energy-efficient buildings project

The SCORES project is a 4-year project on energy-efficient buildings. The goal of the project is to develop an energy system for buildings and demonstrate it in practice.

SCORES focuses on increasing the use of renewable energy in residential buildings at low cost. The project also looks at new compact hybrid storage technologies that optimise the use (supply, storage, and demand) of electricity and heat in residential buildings.

SCORES was launched in November 2017 and is funded by the European Union, as part of the Horizon 2020 call on Energy-Efficient Buildings. TNO coordinates, promotes smooth collaboration, and strengthens the consortium from within.

Get inspired

VoltaChem Year Event 2025

Renewable syngas: essential for industrial decarbonisation

Western North Brabant becomes hotspot for biobased building blocks for the construction industry

New facility to develop circular plastics on an industrial scale

Time setters: Smart windows bring climate-neutral living a step closer