Equipment for additive manufacturing

The future of food and pharmaceuticals is sustainable and personal. Creating tailored solutions to current and future food and pharma challenges requires a multidisciplinary approach that combines material knowledge, equipment expertise, and innovative business thinking. TNO Equipment for additive manufacturing applies its creativity, engineering expertise, and sector-specific knowledge to explore the concepts, equipment, and processes needed to create novel and future-proof food products and personalised medication.

Addressing industry challenges

From stimulating the transition towards alternative protein sources and addressing specific nutritional needs, to enabling effective medicine doses, release profiles, or polypill solutions. They all begin with equipment that can consistently produce novel, high-quality products. Our multidisciplinary Equipment for additive manufacturing team consists of experts in mechatronics, engineering, chemistry, industrial design, electronics, and software.

Together with other specialists within and outside TNO, we research, design, and build the solutions that address current societal challenges. We combine our equipment development expertise with specific food and pharma domain knowledge to translate our clients’ questions into the most effective solutions by:

- Conducting process research that optimises the production of personalised nutrition, alternative protein products, as well as medicine concepts and use cases.

- Delivering proofs-of-concept for new product creation, often by producing samples in our own labs using our clients’ materials.

- Developing equipment made to our clients’ exacting standards and specifications.

Facilities for acceleration

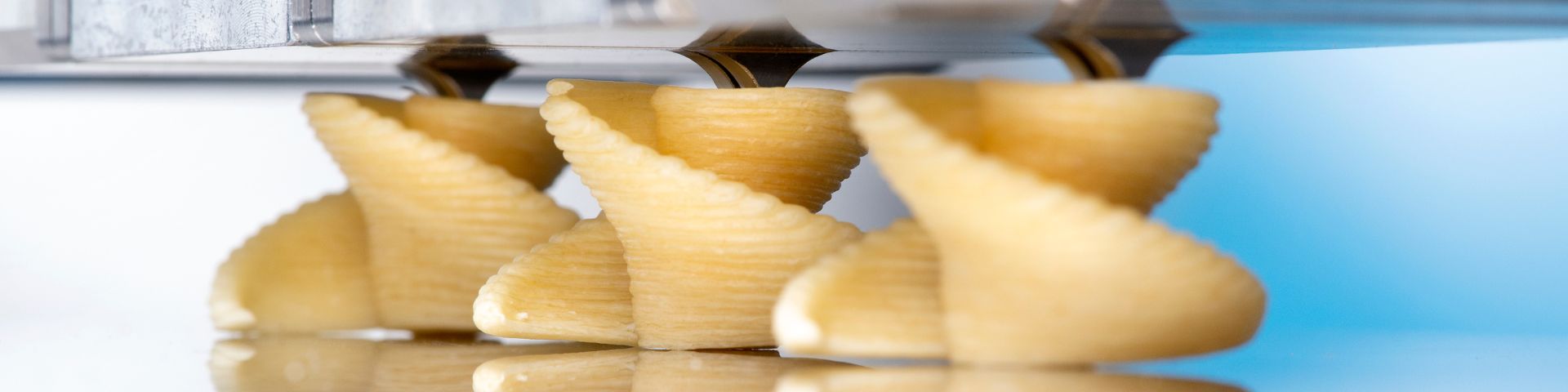

We operate within three labs, fully equipped to address food and pharma challenges with advanced processing technologies, including 3D printing. In addition to dedicated labs for both food and pharma research and development, we build and modify equipment in our workshop. The labs contain beyond-state-of-the-art 3D printing and other setups that were developed in-house, including facilities for:

- High-precision extrusion printing.

- High-speed, high-power extrusion printing.

- Multi-nozzle extrusion printing.

- Separate and combined selective laser sintering and binder jet printing.

- An innovative protein structuring setup.

- A personalised nutrition production setup.

Personalised nutrition solutions

As the demand for personalised nutrition continues to grow, TNO Equipment for additive manufacturing has created a highly innovative Personalised Nutrition Production System that incorporates the latest printing and dosing technology. This enables the fully automatic production of fully personalised food products. In close cooperation with international food and ingredients companies, this system has been used to explore the opportunities for personalised food solutions for military personnel or for patients recovering from a stay in an Intensive Care Unit.

In addition, we accelerate and expand our own expertise by partnering with other domain experts. In the Digital Food Processing Initiative (DFPI), we collaborate with Wageningen University & Research, and Eindhoven University of Technology to develop digital manufacturing systems that will enable personalised, sustainable, novel, and healthy food solutions.

Medicine tailored to individual patient needs

Achieving personalised pharmaceutical solutions requires not only the right equipment, but also the right insight and partnerships with sector stakeholders. We work closely with hospitals, pharmacies, pharmaceutical companies, formulation companies, and ingredient suppliers to, among other things, explore possibilities to 3D-print personalised medication, polypills, or tablets with specific release profiles. Our strong partnership with Erasmus Medical Center enables us to supplement our equipment and research expertise with the right pharmaceutical expertise to ensure effective solutions.

Get inspired

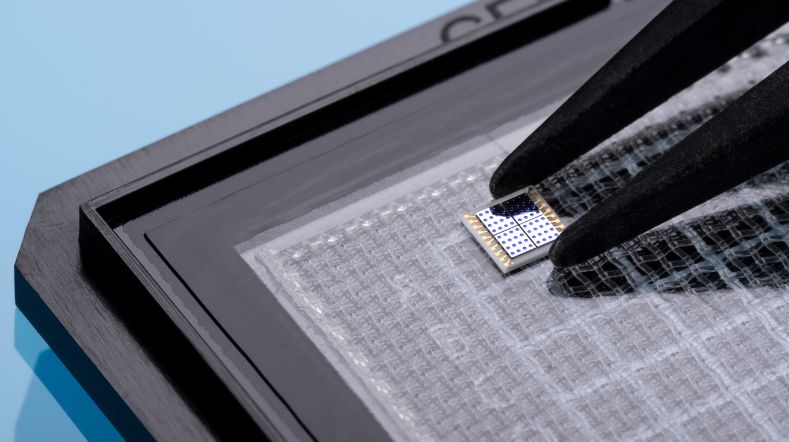

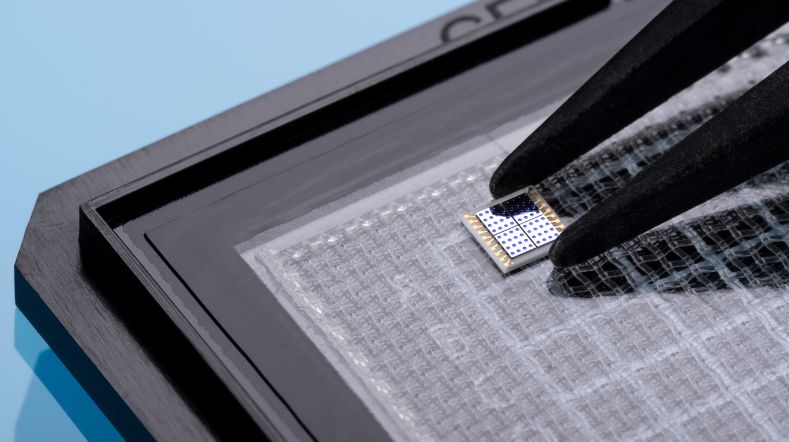

Demcon joins TNO and University of Twente to accelerate photonic chip innovation

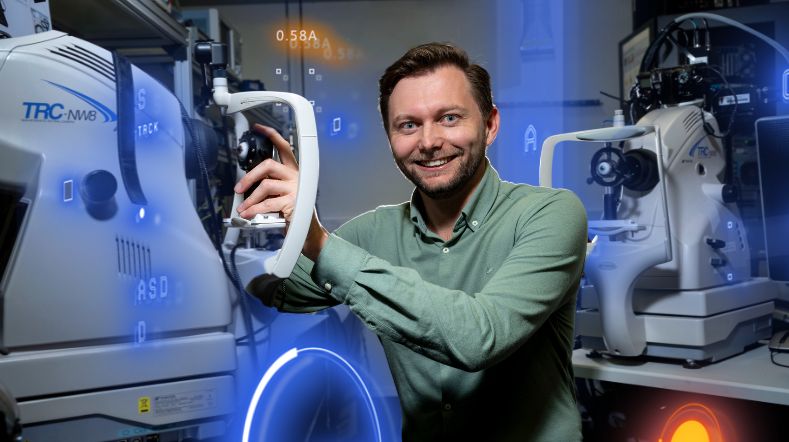

Developing accurate and inclusive medical devices

3D printed food: the future of personalised nutrition

Hybrid and printed electronics

Thin-film electronics