Hybrid and printed electronics

Industry applications for thin, flexible, stretchable, and conformable printed electronics are nearly endless. From energy storage and sustainable electronics to healthcare and advanced photonics. The experts at TNO Hybrid and printed electronics develop enabling technologies and offer application support to ensure the fastest time to market for advancements in our sustainable and digital society.

Addressing industry needs

While printed electronics enable manufacturers to develop and design the devices of the future, the technologies needed to realise these innovative systems are often out of reach. TNO offers additive manufacturing, process engineering, and hybrid integration expertise to ensure all the possibilities of the technology are close at hand. Whether companies aim to solve a specific electronics challenge, want to commercialise technologies we develop, or wish to enter the market with new and innovative products, TNO offers the expertise and facilities to support them.

Our process engineers, material scientists, physicists, chemists, and other experts examine the possibilities of printed electronics and hybrid integration, and demonstrate how organisations can apply these technologies to develop the electronics of the future. We use nano- and microelectronics, nanotechnology, industrial biotechnology, advanced materials, photonics, and advanced manufacturing technologies to create both the equipment needed to manufacture these electronics, and also to ensure their effective application in the industry. From pick-and-place technologies for microLED displays to semiconductor chip packaging to medical wearables.

FononTech: optimised component manufacturing

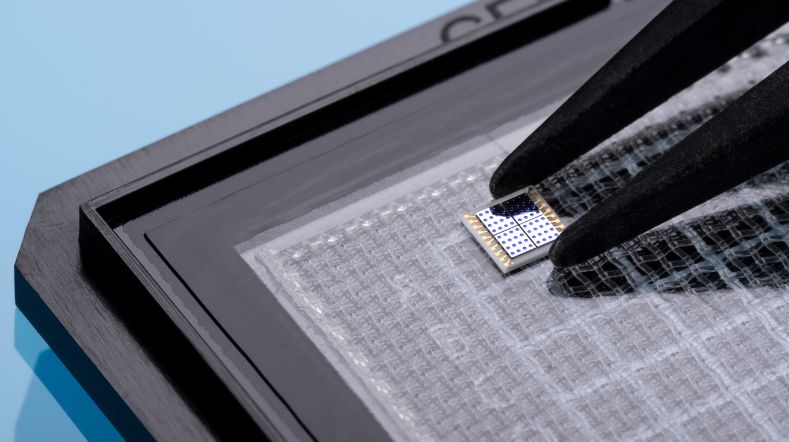

Electronic devices are getting smaller and smaller, but their processing power needs to continue to grow. Impulse Printing, a revolutionary technology developed by TNO at Holst Centre, addresses this challenge with the ability to print micron-sized features and complex 3D interconnects using additive manufacturing. The technology is now available at FononTech, a TNO spin-off company.

The future of healthcare

Wearable devices offer flexible and comfortable ways to measure and monitor health both inside and outside a clinical setting. And the next generation of medical wearables are designed and demonstrated at TNO at Holst Centre. In addition to wearable devices that are more comfortable and provide more stable measuring capabilities, TNO can also integrate additional functionalities into a wearable form factor, to enable the measurement of even more relevant health parameters. From ECGs and ultrasounds to autonomous diagnostic and treatment devices, TNO technologies are at the heart of some of the most advanced and affordable healthcare solutions available.

TracXon: bringing printed electronics to life

Many companies want to include printed electronic devices and wearables in their product lines. But they often don’t have the in-house capacity to manage this complex production and integration process. Through TracXon, a TNO spin-off, companies can bring their innovations to life with printed electronics production experts.

Making electronics sustainable

Additive manufacturing is one of the keys to more sustainable mobile phones, televisions, home appliances, and more. By replacing traditional components with recyclable substrates and materials, printed technologies can benefit the planet by reducing waste, enabling higher levels of electronics recycling, and addressing resource depletion concerns. TNO puts its industry knowledge and materials expertise to work to explore and validate materials and substrates, design the key enabling technologies for integration and device production, and enable manufacturers and suppliers to confidently offer the market more sustainable products.

Next-generation microelectronics and photonics

Experts from TNO Hybrid and printed electronics contribute to several Joint Innovation Centres working on advanced chip technology and photonic systems. For example, in CITC we enable the creation of advanced semiconductor chip packaging at a lower cost and in a more sustainable way. Through PITC, we are helping to develop integrated photonics systems for application in LiDAR, with our hybrid and additive manufacturing technologies.

Want to solve your electronics challenges with the latest printing and hybrid integration technologies? TNO Hybrid and printed electronics is ready to take your ideas from the drawing board to the production line. Contact us today for advice and applications tailored to your specific industry needs.

Get inspired

Demcon joins TNO and University of Twente to accelerate photonic chip innovation

Developing accurate and inclusive medical devices

3D printed food: the future of personalised nutrition

Equipment for additive manufacturing

Thin-film electronics