Thin-film electronics

Since 2008, the experts at TNO at Holst Centre have been perfecting techniques for thin-film technologies and how to realise functional electronic devices with these manufacturing solutions. Over the years, these manufacturing technologies have matured and are widely employed in industry. Based on our expertise, TNO is currently developing various new applications with an emphasis on intricate 3D structures over large areas. We provide a pathway to mass-production and a fast route to market for the innovations we enable and support. These include applications in a range of industry segments, from energy storage to healthcare to chip packaging and much more.

Driving industries forward

TNO at Holst Centre is a strategic collaboration between TNO and imec, designed to accelerate the application of innovations in increasing numbers of application domains that aim to reach societal goals. In the case of thin-film technology, Holst Centre has developed technology originally intended for displays, televisions, and screens. The team’s expertise has advanced towards the realisation of thicker material layers that, with the right optimisation of patterning, lead to accurate and effective production of 3D thin-film structures over large areas. Today, we are applying these techniques to enable solutions for some of society’s biggest challenges, and helping organisations meet their production, efficiency, or optimisation goals.

Partnering for acceleration

When it comes to manufacturing the technologies that will power our future, the experts at TNO can guide and co-develop solutions that are effective, efficient, scalable and safe. And while the applications for thin-film technology are varied, their impact is undeniable. Most recently, we have been focusing on:

1. Next-generation battery technology

The production of stable, powerful, and sustainable batteries for everything from mobile phones to electric vehicles. TNO’s innovative manufacturing techniques – in combination with its recently installed battery pre-pilot line – enable companies to scale the production of 3D and solid-state batteries to deliver exceptional performance, rapid charging, high stability, safety, and sustainability.

2. High-tech electrolysers

Thin-film electronics manufacturing technology is at the heart of a new generation of electrolysers capable of converting water into hydrogen and oxygen in a highly efficient, cost-effective, and circular way with significantly less iridium. By re-using gained knowledge from the battery domain, we enable high-tech companies to open up a new market, while concurrently working on a sustainable future. We are working within the NXTGEN Hightech program dedicated to develop the third-generation electrolysers that will fuel our sustainable future.

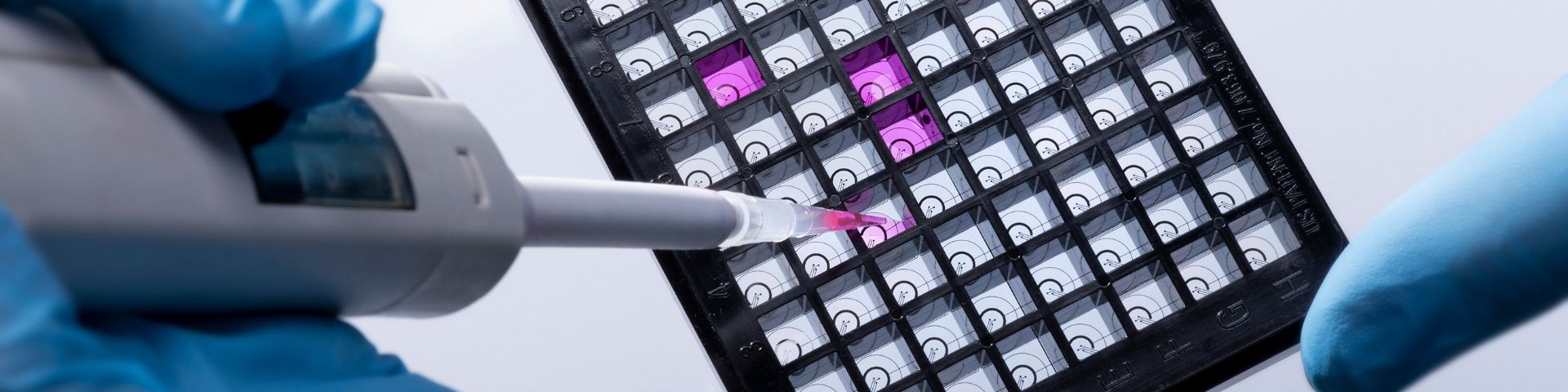

3. Organ-on-a-Chip technologies

Our contribution to Organ-on-a-Chip (OoC) technologies will establish uniform and scalable manufacturing solutions that make OoC widely available. In collaboration with TNO’s Healthy Living and Work unit, TNO is applying its thin-film expertise for improved microfluidic functionalities and sensor integration. This will help improve readouts of stability and/or biological reaction of experimental tissue in functional tests, for example in pharmaceutical companies’ development pipeline for new drug candidates. The manufacturing technology, together with the biological insights from TNO Healthy Living and Work colleagues, will enable more predictive models for early-stage pharmaceutical development with less animal testing.

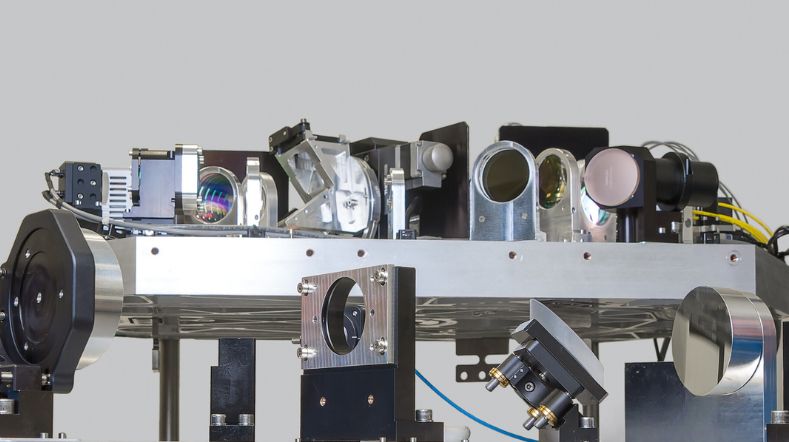

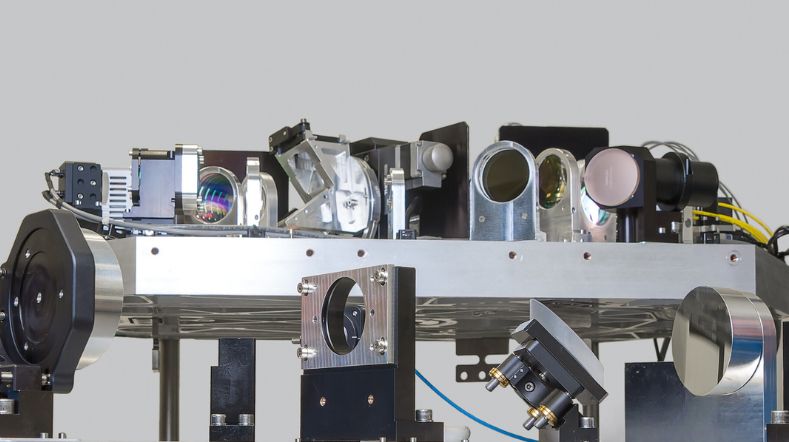

4. Advanced Chip Packaging & Integrated Photonics

TNO works in a variety of partnerships to optimise and expand heterogenous integration and advanced chip packaging capabilities. With the thin-film technology expertise moving towards more 3D functional structures, other application domains have come into view. Our Thin-film electronics team’s expertise – combined with our Hybrid Printed Electronics capabilities – is now also applied for advanced chip packaging, such high-power and/or antenna-in-package applications in collaboration with TNO at CITC. Further in the future, packaging knowledge and know-how will also be employed for the integrated of photonic chips in collaboration with PITC.

5. Multiple industrial applications

TNO began its work on thin-film technology to advance the flexible display and screen manufacturing process. Today, our expertise is put to use in everything from security systems to advanced photonics, and from healthcare to sustainable energy.

Collaborating for impact

Companies interested in learning how thin-film technology can accelerate, optimise, or revolutionise production and energy storage or develop new market segments are encouraged to get in touch. Together in contracted partnerships or consortia, TNO is ready to address the challenges of the future with the technology it has optimised today.

CITC: Advanced Chip Packaging

In 2019, TNO and Delft University of Technology founded CITC: a non-profit, joint innovation centre that specialises in heterogenous integration and advanced chip packaging technology. Today, CITC is a thriving community of academic, business and government partners aiming to solve technological challenges and optimise chip performance.

LionVolt: Next-Generation Batteries at Work

In 2020, TNO at Holst Centre successfully spun off its 3D solid-state battery expertise in LionVolt: an organisation dedicated to developing and scaling 3D solid-state batteries at scale. LionVolt’s technology delivers 200% higher battery performance at half the weight of traditional Lithium-ion batteries, with 100% safety.

Get inspired

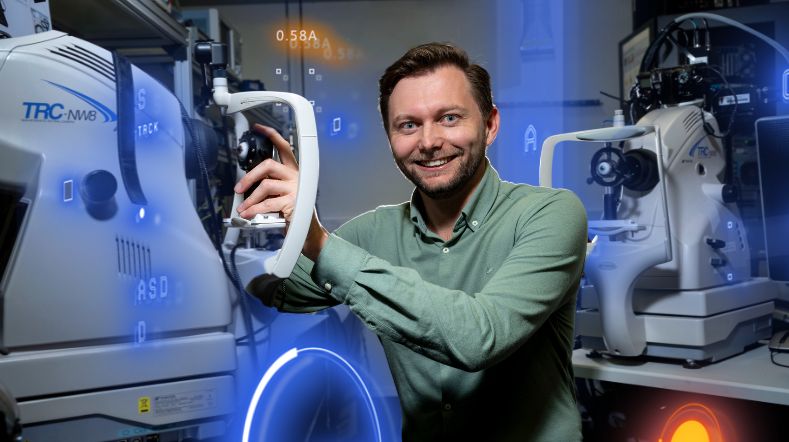

Time setter story: Nienke Dijkstra

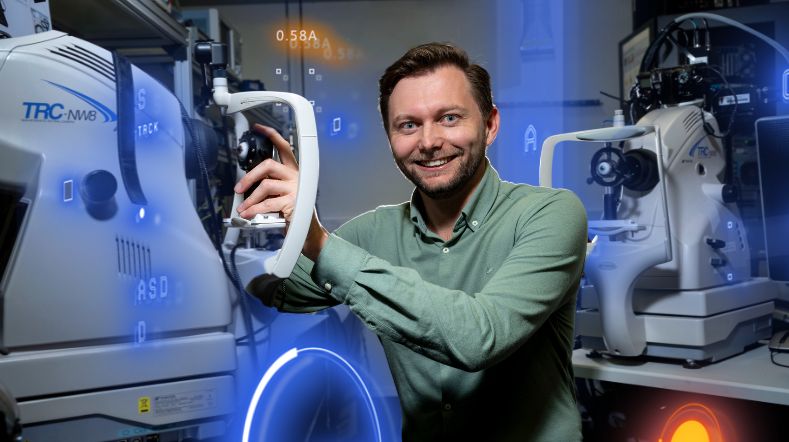

Developing accurate and inclusive medical devices

3D printed food: the future of personalised nutrition

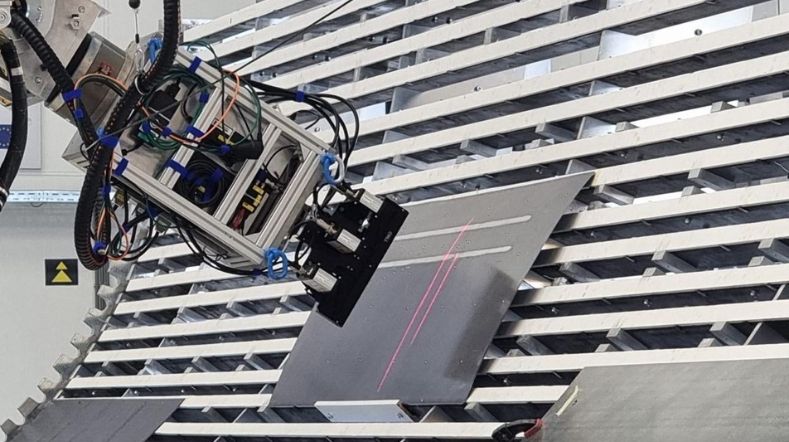

Non-destructive inspection

Optics