Contamination control for semiconductor equipment

TNO is a specialist in contamination control for extreme ultraviolet lithography (EUV). We develop modules, research equipment, and strategies for the contamination control of EUV lithography scanners and materials and have been a trusted partner of ASML and Carl Zeiss in this regard for 20 years.

Leader in contamination control

We are specialists in contamination control research. We develop instrumentation and strategies for applications with the most challenging requirements in the High Tech Industry, including EUV lithography. The goal is to mitigate both particulate and molecular contamination. We have advanced facilities for the inspection and analysis of contamination, cleaning equipment, and setups to research the effect of EUV light and plasma. Our ultra-clean equipment is also suitable for validation of EUV masks.

Our contamination control infrastructure

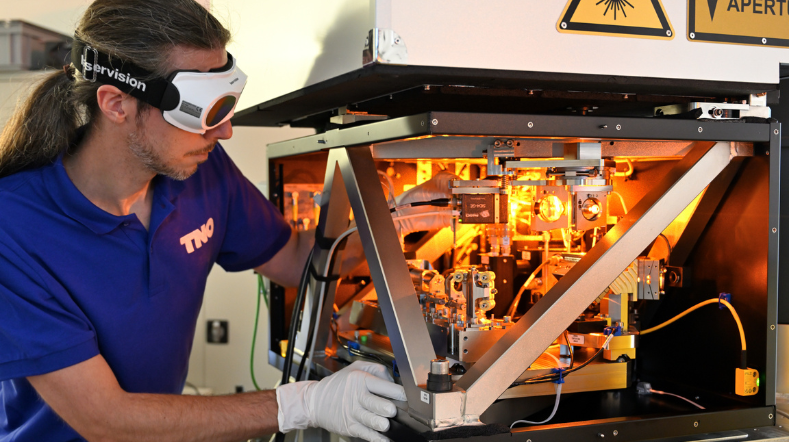

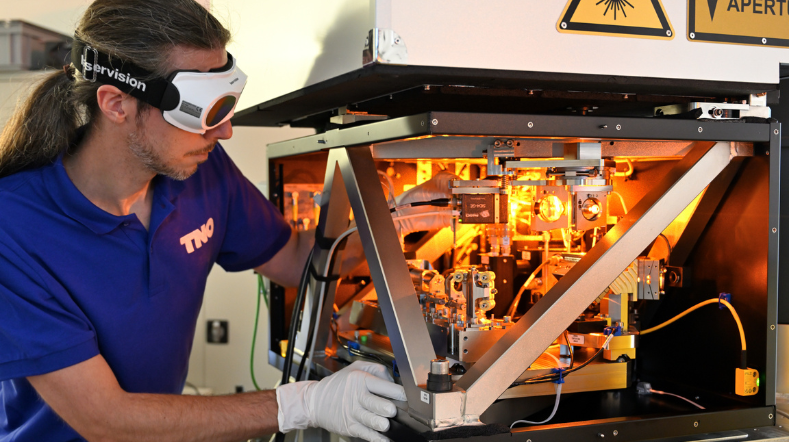

TNO has expanded its research and development (R&D) infrastructure. This second EUV exposure setup including surface analysis equipment was put into operation in 2018. It is used for research into materials such as optics, reticles, and pellicles, in collaboration with various parties in the EUV lithography field, including materials suppliers, end users, and equipment developers.

Functionalities:

- The system accepts a variety of sample sizes, including standard EUV reticles with or without pellicles.

- EBL2 also has an XPS system that can analyse EUV masks and pellicles, including a functionality for the production of a ‘defect map’.

- Automated sample handling accepts SEMI-standard dual pods and maintains NXE compatibility for particle contamination on the back end.

- The system is suitable for exposure of samples to very high doses of EUV, and for returning the reticles for use in a wafer fab.

| Category | Specification |

|---|---|

| Optical power |

>1 W in 2% BW at 13.5 nm (‘IB’) (10 W in OoB ((10-20 nm )) at 3 kHz |

| Intensity | >1 W/mm2 IB in focus at 3 kHz |

| Cross-sectional optical focus | 1 - 30 mm diameter (adjustable power density) |

| Source frequency | 1 Hz - 10 kHz (default 3 kHz) |

| Sample size | Max. 152x152x20 mm (EUV mask + pellicle possible) |

| Dose control | <20 % with source feedback turned off |

| Continuous exposure time | >100 hours |

| In-vacuum analysis techniques | Ellipsometry and XPS |

Facility for exposure and analysis: EBL2

We have been researching the interaction between EUV and different materials since 2000. To facilitate the ASML power roadmap, a second facility was developed for EUV exposure and in-situ surface analysis, also known as EBL2. This system helps customers evaluate their materials and components for NXE-relevant EUV radiation and environmental factors so as to increase the service life and prevent contamination.

The EUV Beam Line 2

The main facility for EUV development is the EUV Beam Line 2 (EBL2). This integrated vacuum system consists of a vacuum chamber, in which to carry out the EUV exposures in a controlled environment, and an XPS for surface analysis. In this system, samples can be transported between the test environment and the XPS without disturbing the vacuum.

In the vacuum system of the EBL2, samples are exposed to EUV radiation for extended periods of time in a controlled, representative environment. An in-situ ellipsometer with imaging is available for real-time monitoring of exposure progress.

Get inspired

Pioneering with a purpose: The Netherlands at the forefront of quantum innovation

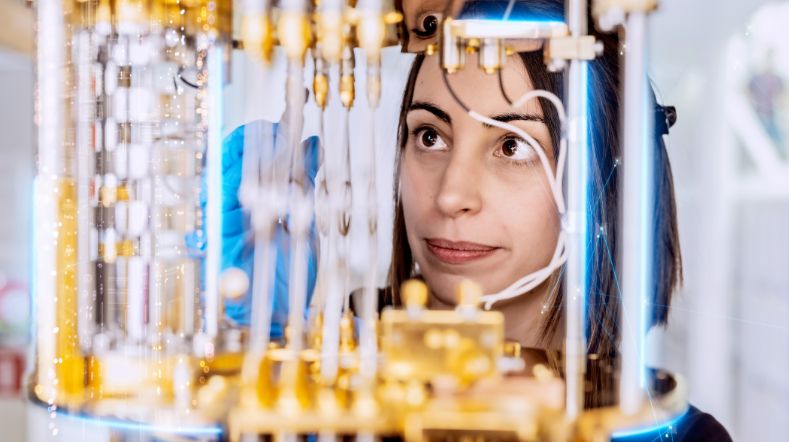

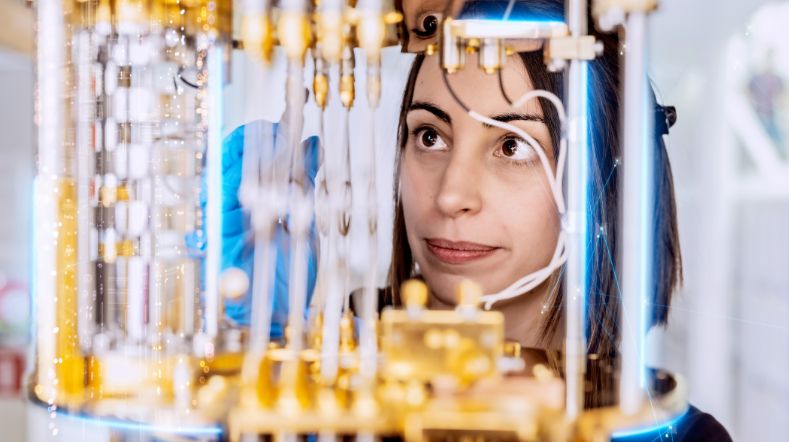

Pioneering on the edge of physics: quantum chips tested faster and faster

How TNO’s Ines Corveira Rodrigues shapes tomorrow's quantum world

Optics

Art and quantum: student team renders superposition tangible with TNO