Scale up: manufacturing throughput and quality

As a manufacturing company, how do you switch from one product to another? Without losing time because you, for example, need to manually reprogram or recalibrate robots. How can you increase production while maintaining quality at a time of staff shortages? And how do you leverage data, digitalisation, AI, and robotics in the process? In the domain of manufacturing throughput and quality, TNO is working on solutions that enable robots, sensors, and production machines to flawlessly interact and autonomously adapt to changing production flows. In this way, the power of robotisation and automation can keep you producing flexibly and competitively.

Fast and flexible production

Do you as a manufacturing company have to deal with many different products in small batches? If so, fast and flexible manufacturing is one of the biggest challenges you face. You don’t want to waste time switching from one product to another. And you want to be able to immediately deliver high-quality products. You’re undoubtedly aware of the many possibilities industrial robots can offer, but since each new task would require their reprogramming, you find yourself quickly falling back on manual labour. TNO is revealing a different way.

Robotisation and automation reduce production costs. Switching the production process is still mostly done manually. Doing so takes time and effort, which means a loss of productivity and revenue. Robotisation and automation have a key role to play here. TNO offers several solutions to shorten lead times and reduce production costs. We believe that, in the future, production machines will be able to adapt autonomously and be programmed automatically. This will enable single-piece production at the cost of mass production.

Enabling single-piece production at the cost of mass production. That’s what manufacturing throughput and quality is all about. The main challenge is to get intelligent robotics, software, smart sensors, cells, and production machines to work together flawlessly. And to adapt without human intervention.

One of the biggest challenges for the manufacturing industry is becoming hyper-efficient. Factories should be able to switch without making mistakes (i.e. with zero defects). Moreover, they should not waste time (zero programming). And this also needs to apply to ‘low volume, high mix, high complexity’ product ranges.

Automation and flexibility are difficult to combine

Robotisation is an important innovation from which the manufacturing industry can benefit. But because programming is time-consuming, manufacturers will often turn to humans instead of robots for small batches. Robots are often left idle in manufacturing companies, even though they could be producing without any loss of time thanks to this technology.

Production automation and flexibility are difficult to combine. Reconfiguring a production line, reprogramming robots for a different task, generating new assembly instructions, rerouting the logistics of parts. Most of these adjustments needed to switch from one product to another are done by humans.

Digitalisation is the ultimate key

Where these adjustments are now mostly done manually, digitalisation offers a solution. The future of manufacturing lies in increasing autonomy. That is the ultimate key to successfully combining automation and flexibility. This will allow companies to operate competitively with autonomous flexible production.

Help from intelligent robots

We have already started realising this vision and creating the first concepts. First, we are developing applicable solutions to serve the first-line needs of the manufacturing industry as quickly as possible. Consider, for example, a zero programming solution that automatically plans robot paths for each new product. This already has a significant impact on productivity.

At the same time, we continue to develop knowledge. By bridging gaps in the overall solution by combining partial solutions into an integral solution, we are laying the foundation for the digitalisation of the manufacturing industry. Consider adding camera vision to robotic applications, enabling robots to see and react to their environment as they perform their tasks. This already takes flexible production one step further towards autonomy.

Deploying a robot requires more than just its installation. The robot has to fit into the workflow. We strive for integral solutions. Awareness is growing that we need to seize these opportunities. We launch projects and collaborate in fieldlabs to find practical solutions. We welcome companies to experience what is possible and test new solutions in a safe environment.

Real-world challenges

Automatic quality control of incoming new or reused goods. Real-time insight into the stage of the production process, continuous analysis to identify potential bottlenecks, and specific instructions to help human operators run the process optimally. And that is just a fraction of what is already possible thanks to robotics, smart sensors, and digital technology. For example:

Technology development to further optimize the functionality of machines and robots. Examples include machine learning and autonomously operating robots to perform operational actions. Smart robotization is key here, such as for picking fruit or other crops. Or autonomous robots for performing security and inspection tasks in industry.

Together with UTwente, TNO works on value-added solutions for robots in the robotics innovation hub i-BOTICS.

Effective interaction between employees and robots is the cutting edge at the Robohouse in Delft.

The remanufacturing lab is a testing and experimentation facility for manufacturing, with the aim of stimulating digital innovation in manufacturing and sustainability.

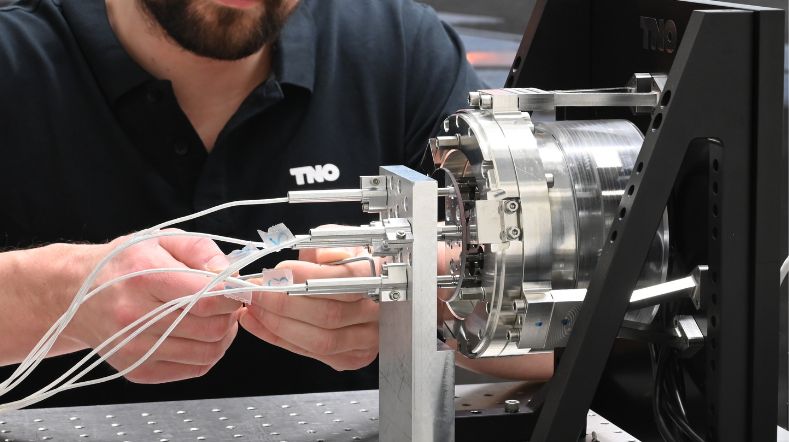

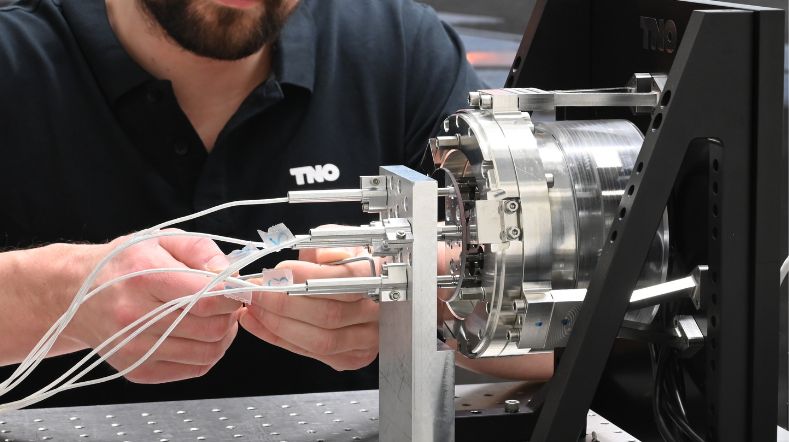

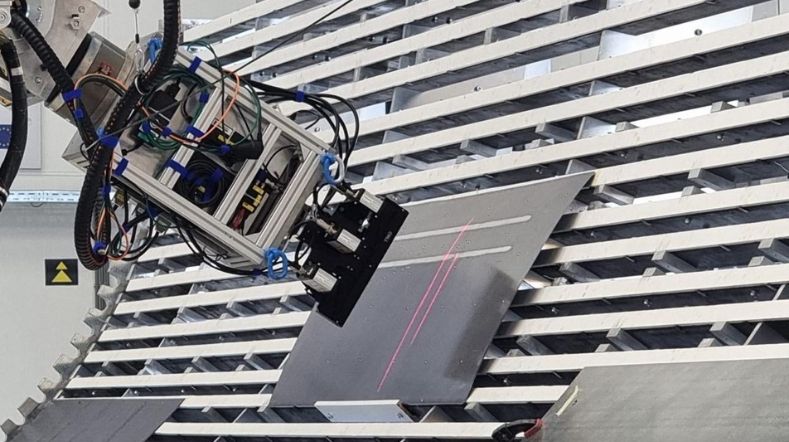

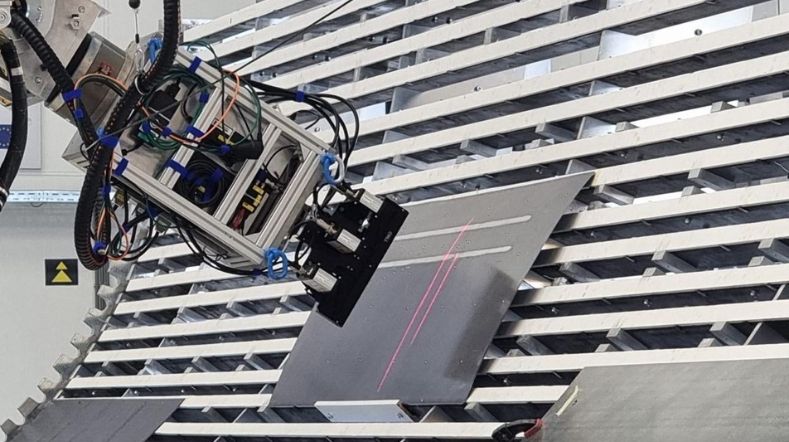

TNO develops autonomous production cells for in-line quality assurance technology (metrology) for metal bonded and composite structures based on patented contactless ultrasound technology named Direct Velocity Mapping (DVM). For high tech applications with stringent quality requirements, this technology offers a fast, clean and automated process thereby improving the time needed for in-line and in-service inspections.

Video automated workflow generation from scanning to planning to (re-)manufacturing.

Get inspired

TNO spin-off Scenexus secures 1.6 million euro investment

Non-destructive inspection

Strategic autonomy: digitalisation and value chain integration

Productivity: manufacturing variability

Optomechatronics