Non-destructive inspection

A non-destructive inspection (NDI) technology is a key aspect of product quality assurance and supports the aim for zero defect manufacturing. The technology is an aspect of mechatronics and optomechatronics which in turn is part of the Key technology cluster Engineering and fabrication technologies of the National Technology Strategy.

What is non-destructive inspection using direct velocity mapping?

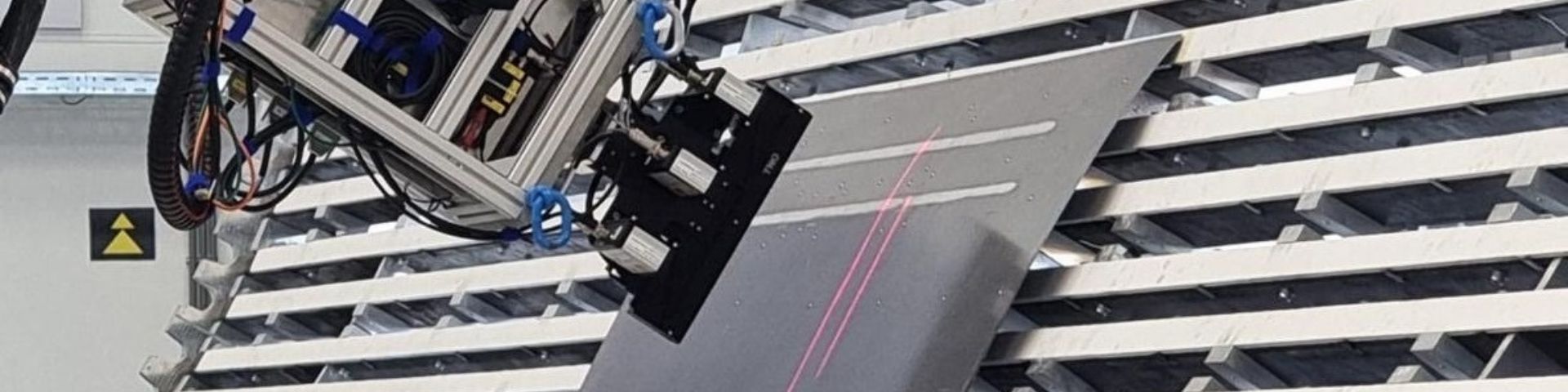

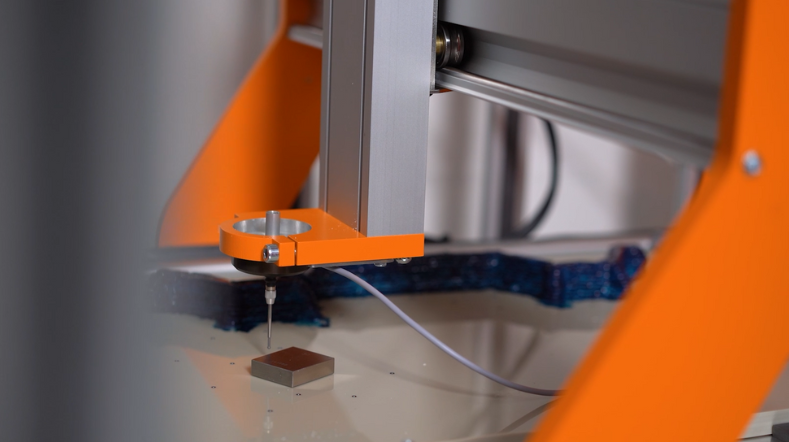

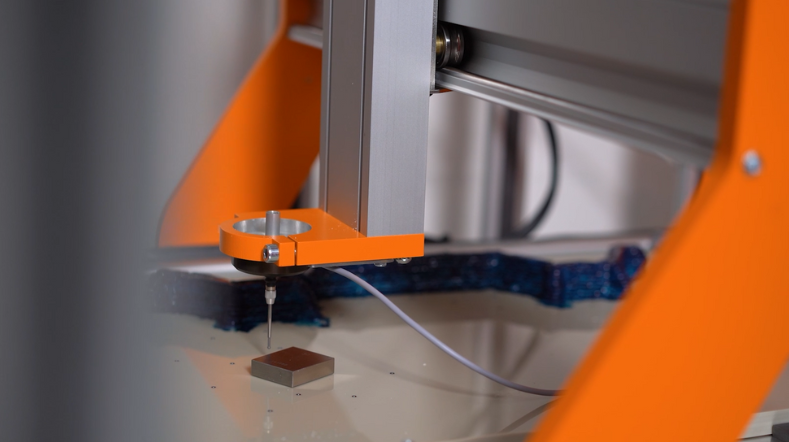

The DVM NDI technology offers a fast, non-contact, scalable and clean process making it very suitable to inspect large surfaces in an automated way which is a combination not offered by existing benchmark NDI technologies. The DVM NDI technology involves applying Lamb waves into a structure and detecting irregularities in Lamb wave velocity and/or amplitude as a result of damage using a Micro-Electrical Mechanical System (MEMS) array. The combination of advantages of DVM NDI make it very suitable to be used for in-line manufacturing and in-service inspections using robots.

Non-destructive inspection in manufacturing industry

NDI is currently widely used in the aerospace manufacturing and maintenance industry but may also be applicable to other sectors, in particular when stringent quality assurance requirements are involved. In Europe the aerospace manufacturing sector is tiered with tier 0 companies involving Airbus, Dassault Aviation, Leonardo, and Saab. Tier 1 suppliers include for instance GKN-Fokker, Daher, AERRNOVA and Premium AEROTEC. The list of subsequent tiers is quite extensive and within the Netherlands the Netherlands Aerospace Group has a list of members as an example.

Current research about DVM NDI technology

The research has shown promising results and in particular for defects that influence the Lamb wave pattern due to a change in thickness or disbonds/delaminations. Current research activities involve determining the operational design domain and improving the key process variables such as robustness, measurement and processing speeds.

Paper non-contact inspection using Lamb waves

This paper presents a non-contact inspection method for metallic and composite parts using a MEMS-sensor array to record the full wavefield.

Get inspired

3D Nesting: precision quality control and manufacturing efficiency

SEAMIIC: Autonomous parts handling and quality control

Partnering for mutual progress

TNO spin-off Scenexus secures 1.6 million euro investment

Scale up: manufacturing throughput and quality