Productivity: manufacturing variability

Harnessing the potential of robotisation and digitalisation to produce a specific part at a cost more in line with mass production. In other words, a production environment where robots can be used flexibly and man and machine can work together smoothly. That is the power of manufacturing variability.

Automation and flexibility are difficult to combine. But it can be done. Thanks to clever software that reprograms robots with each new task. This enables solutions that make robotisation an interesting option in production environments where many different parts need to be manufactured – in small volumes or even as a single part. There are also opportunities to quickly set up a production line where robots and humans complement each other well.

Operator central

Adjusting the configuration of a production line or reprogramming robots – these are the kind of tasks still mostly performed by humans at manufacturing companies. But thanks to advanced robotic solutions, it is no longer necessary to make all those adjustments manually. Hence, autonomous production is now also an option for small series. This does, however, involve a major automation push that requires a slightly longer lead time. After all, it’s not as if ready-made robots can be driven into a factory and put to work straight away.

Step by step towards an integral solution

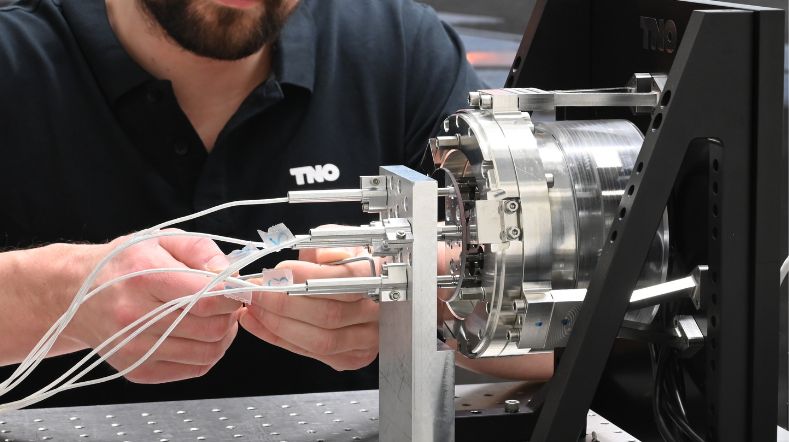

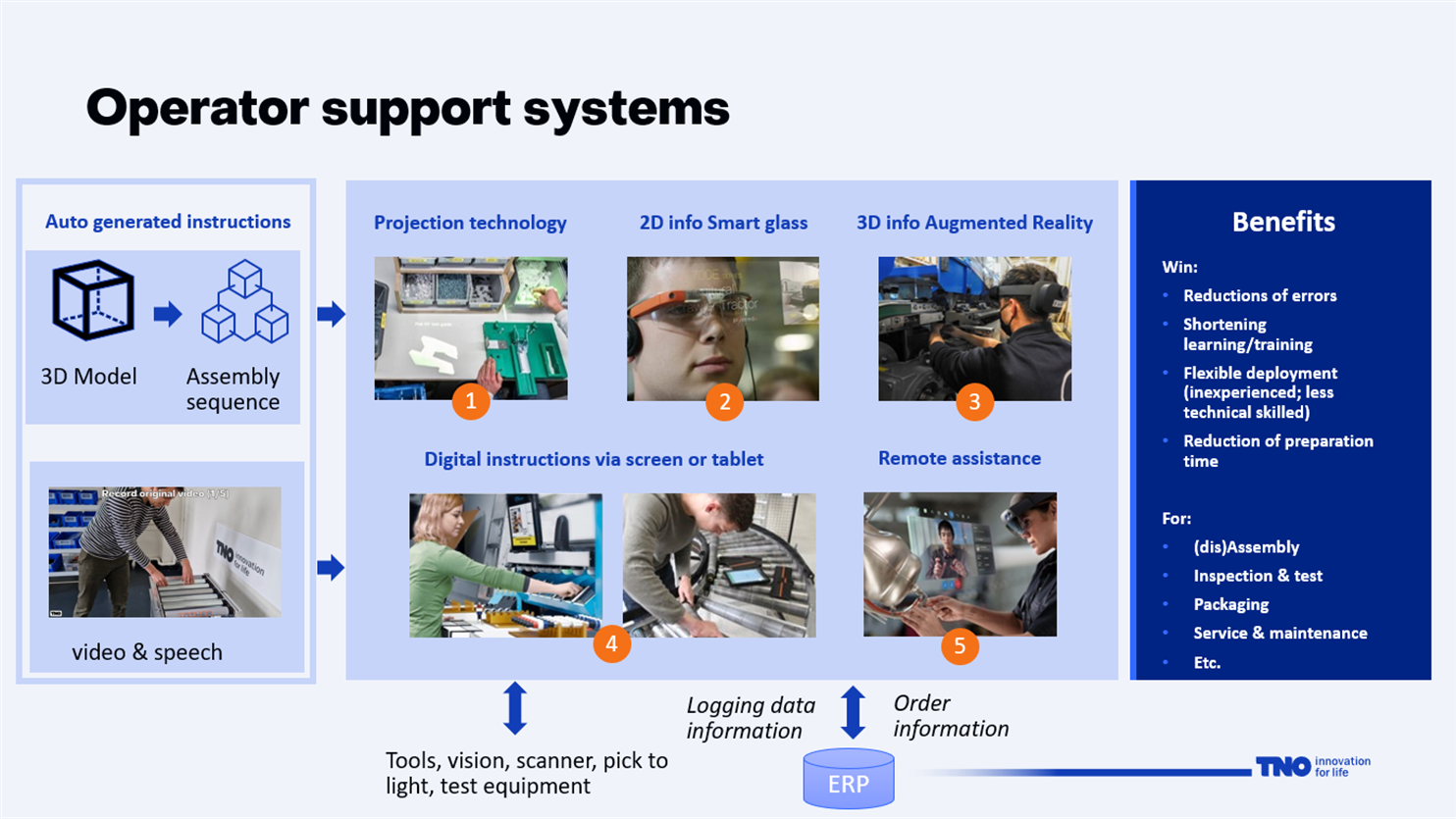

At TNO, we help manufacturing companies to achieve autonomous, flexible production. We do this step by step. By applying partial solutions, we strive to achieve an integral solution in which all the necessary elements are in place to achieve manufacturing variability. We often use intelligent camera systems to help us with this. We not only use them to visualise all operations, analyse them in real time, and identify bottlenecks, but also, for example, for VR and AR applications that give human production workers visual instructions on the work to be performed in the workplace.

Smooth collaboration between humans and machines

Also worth mentioning: collaborative design. This is often a game changer as it encourages and optimises human-machine collaboration. And increasingly sophisticated robotics and digital tools are making that collaboration smoother by the day.

Experimenting during field labs ‘test before invest’

Developments in flexible manufacturing are moving fast, making manufacturing variability an interesting option for more and more manufacturing companies. To discover what is possible, TNO regularly invites companies to participate in fieldlabs. During the projects launched there, participants are often impressed by the technological and digital solutions already available today. Such fieldlabs also give them the opportunity to test new solutions and ask questions in a safe environment.

Practical examples

Innovation and digitalisation have already led to several solutions in practice. TNO focuses on the key technology of engineering and fabrication, which includes the subareas of optomechatronics, imaging technology, actuators and sensors, and digital manufacturing. Examples include:

Pilot at Equinox: Pilot maintenance procedures Equinox.

Smart Wind pilot: Remote assistance in Nacelle.

https://youtu.be/Ze19G7Aw7YU

Using technology to have MBO 2 perform MBO 4 work.

Practical case securing quality and reducing search time during leak tests.

Remote inspection using Spot, the robot dog, based on the Boston Dynamics platform and smart TNO AI applications.

Smart support for service technicians to accelerate product-as-a-service and the implementation of circular business models at HTC Parking & Security. Smart support for service technicians at HTC Parking & Security.

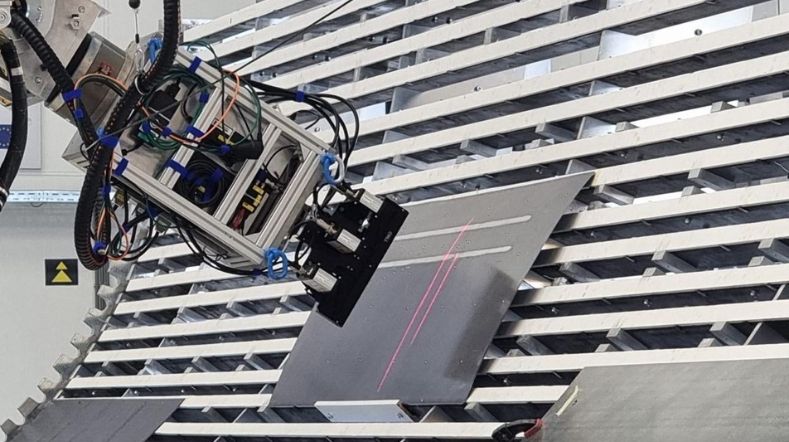

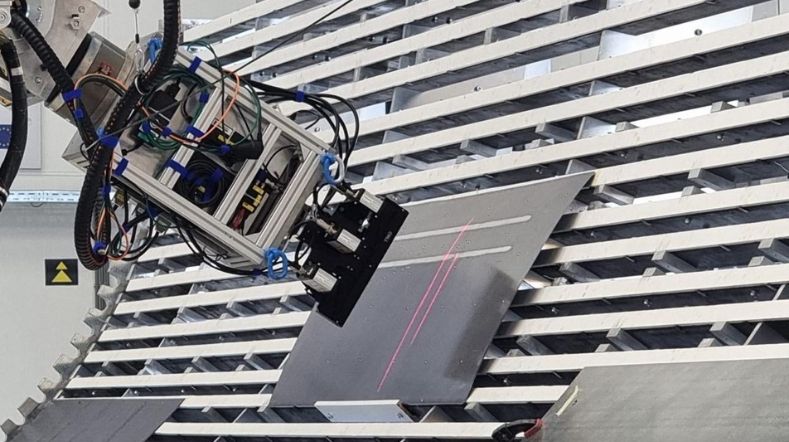

Pilot in laser welding cell at BOZ: securing quality, increasing productivity, and accelerated robot learning.

Bottle lines of beer brewer Heineken invariably face toppled bottles on the conveyor belt. These toppled bottles can lead to major problems in the production process, making their speedy removal a top priority. Until now, this has always been a manual task for operators. But this is not desirable, both for the safety of the working environment and the efficiency of the production process. TNO has developed a robotic solution in collaboration with field lab RoboHouse. The solution was demonstrated on a test bottle line with a robot next to it. A 2D camera on the robot detects the toppled bottle by image processing with a neural network algorithm. The camera images are then used by the robot to follow the bottle and remove it from the conveyor belt (‘vision in the loop’) without having to stop the conveyor belt. Smart calibration options make this robot applicable for use in almost any straight conveyor section.

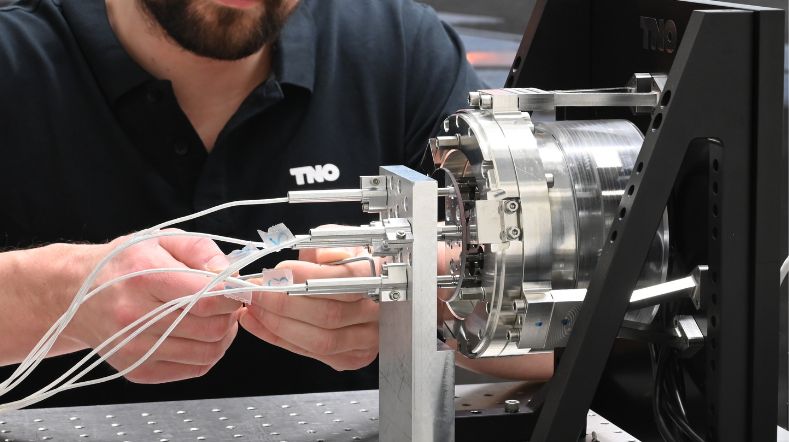

Technology guide instructional operator support

The technology guide has been designed for organisations that are considering integrating instructional operator support but have little or no experience with this technology. The guide focuses on manufacturing and assembly support. (NL)

Get inspired

TNO spin-off Scenexus secures 1.6 million euro investment

Scale up: manufacturing throughput and quality

Non-destructive inspection

Strategic autonomy: digitalisation and value chain integration

Optomechatronics