Using data to improve the factory

Many manufacturing companies are looking for ways to produce unique products ‘first-time-right’ and flexibly, at a price that can compete with mass production. Smart Industry offers opportunities to achieve this. But a Smart and Connected Factory – a digital chain – is often still unfeasible because manufacturing companies don’t have all relevant data available. For example, it isn’t self-evident that a company can read out or manage its entire production line in real time.

Do you recognise this situation in relation to your own business? Are you looking for a way to use manufacturing data to create added value for clients, partners, and your own organisation? We’re offering the opportunity to become part of a network of companies that’s laying the foundation for easy data access to improve processes in manufacturing companies.

We’re working on a plug & play data platform for analysis and factory control that will also enable you to take your production process a step further in terms of digitalisation. With all the opportunities that this offers, it’s a big step towards flexible production at market prices.

Is your manufacturing company ready for Smart Industry?

Smart Industry offers opportunities to produce first-time-right, flexible, unique products at a price that can compete with mass production. This is made possible by the many new technologies and applications being developed in the areas of the Smart Industry wheel – Digital Factory, Connected Factories, Flexible Manufacturing, and Smart Working.

All these applications use data from the field, and experience has shown that many manufacturing companies do not yet have all the necessary data available. For example, companies can’t necessarily read out, or even control, their entire production line in real time.

Without a basic functionality that retrieves data from the factory and makes it usable, the potential of Smart Industry is insufficiently exploited. We can help you implement this basic functionality.

Our goal: to build a solid basis for manufacturing companies to fulfil their Smart Industry desires

Our goal is to lay the foundation for digitalising the factory. This basis will ensure that companies can gain added value from the combination of data, models, and processes. Technological suppliers (e.g., of IT) can develop new applications, enabling manufacturing companies to optimise their production and gain insight into the production process or into returns on planned investments.

In practical terms, this means that, in collaboration with manufacturing and IT suppliers, we’re now working on a future plug & play data platform for analyses and factory control for SMEs. This enables them to:

- obtain data easily from machines

- perform analyses and make decisions

- control machines easily.

Key conditions are that all this should be independent of a specific manufacturer/supplier (no ‘lock-in’) and without the need for an in-house IT department.

The road to data

This plug & play is in development. We’re developing and testing it in collaboration with manufacturing companies and software developers. Our approach is in 3 steps:

- designing a blueprint: based on international Industry 4.0 standardisation from Germany, among others

- implementing a working plug & play data platform based on this blueprint, on the basis of open-source principles, so that it’s accessible to all

- testing and further expanding the platform together with suppliers and manufacturers of IT and other products.

A blueprint for digitalising products

Various partial solutions are already available for accessing data, and Germany’s Industry 4.0, for example, has developed the necessary solutions. The blueprint ensures that we make the most of what has already been devised, by cleverly combining components. The basic principle is that we use open-source software as much as possible and are therefore not dependent on suppliers.

The blueprint then shows how the various components are related and where further detailing is required.

Open-source software that makes data available securely and independently

Software is built on the basis of the blueprint. Promising open-source components (Kafka, Grafana, OPC-UA, etc.) are integrated with a number of practical applications in mind. This makes it possible to work openly and to create software that’s accessible to everyone in a plug & play manner, without the data being out in the open. Anyone who wants to use the software can choose how this is done, and, for example, whether the data is stored locally (on premise) or in the cloud. By adding semantic technology, an important additional simplification is achieved; data is given an unambiguous meaning and is therefore easy to interpret and use.

Validation phase in collaboration with manufacturing companies and IT suppliers

The intention is to test the functionality in short iterations with manufacturing companies and IT suppliers. In this way, we’ll work steadily towards a version that will be made available for testing and initial practical implementation. The results will be incorporated into a new version that’s ready for further professionalisation by IT suppliers. This is necessary to ensure that the software is available to the widest possible audience and that manufacturing companies have the choice to do it themselves or purchase it. In the case of procurement, they can decide how much service to purchase.

We’re looking for manufacturing companies and IT suppliers on the road to the digitalised factory

A 10-party consortium is now working on creating a plug & play data platform for analysis and factory control that includes OEMs, suppliers, and product suppliers, as well as IT suppliers and service providers. We’re also looking for additional:

- Manufacturing companies (OEMs, suppliers) on the road to the digitalised factory. By learning from various practical situations, the solution becomes generically applicable and additional components can be added.

- IT suppliers who want to develop services on the plug & play platform and implement it for manufacturing companies.

The power of collaboration

We offer an existing consortium with parties that have already set to work. As a result:

- we can bear the burden together instead of individually

- we can maximise knowledge-sharing with like-minded parties facing similar challenges

- we have one common way of working, we set the standard for data sharing, and avoid lock-in

- we offer maximum leverage of your investments through additional public investments in this field from Dutch regional and central government, and the EU.

Get inspired

TNO spin-off Scenexus secures 1.6 million euro investment

Scale up: manufacturing throughput and quality

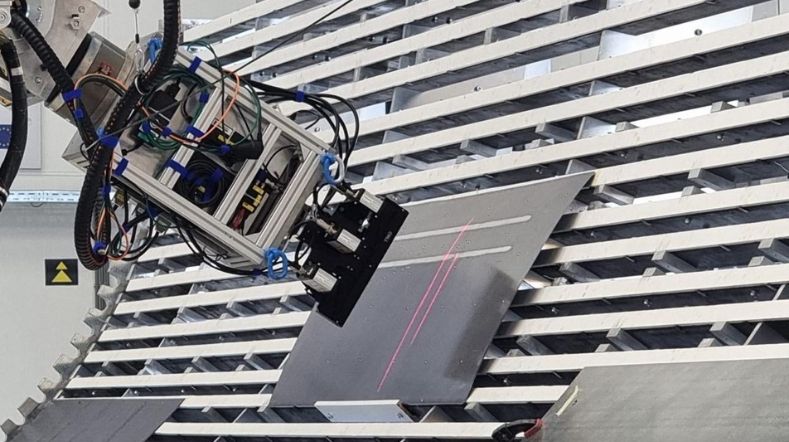

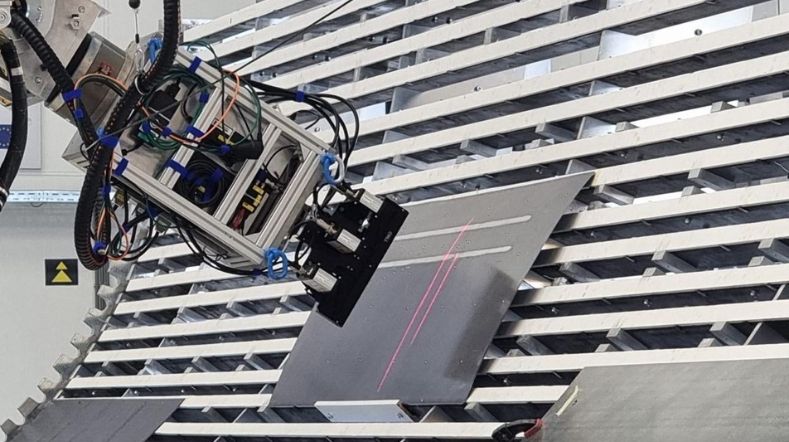

Non-destructive inspection

Strategic autonomy: digitalisation and value chain integration

Productivity: manufacturing variability