Space systems engineering

Developing communication, navigation, and observation satellite instruments, and the complex information systems and terminals through which they operate, often requires working on the edge of what is technically possible. TNO Space systems engineering brings together all the knowledge, expertise, and skills needed to design, prototype, manufacture, test, and qualify state-of-the-art space and scientific instrumentation.

Innovating for the future

TNO Space systems engineering plays a coordinating role in realising instrumentation and systems. We bring together different technical domains to create payloads for earth observation that benefits both people and the planet. We also develop instruments for space observation from the Earth’s surface. Our involvement in ground-based astronomy supports scientists all over the world in their efforts to understand our universe.

From next-generation observation satellites that monitor greenhouse gases and air pollution, to optical satellite systems for broadband communication and instruments for ground-based astronomy, our in-house engineering facilities enable the production of optical and mechatronical systems capable of enduring extreme conditions. We transform concepts into space-qualified, mission-critical equipment that will drive the future.

Multifaceted expertise

For more than 60 years, TNO has been developing space instrumentation and building a proven track record of expertise in early studies, architecture, design and manufacturing, testing, and calibration. Space systems engineering is dedicated to offering the most effective ways to transition from conceptual designs with low Technology Readiness Levels to fully functioning, space-ready hardware and control prototypes. From research and advice to manufacturing and testing, we ensure that each team working on these highly precise satellite systems has the support and insight they need to deliver beyond expectations. We divide our expertise into six key focus groups:

- Project management

- System architecture and engineering

- Product assurance

- Manufacturing, assembly, integration and testing

- Optics manufacturing

- Instrument manufacturing

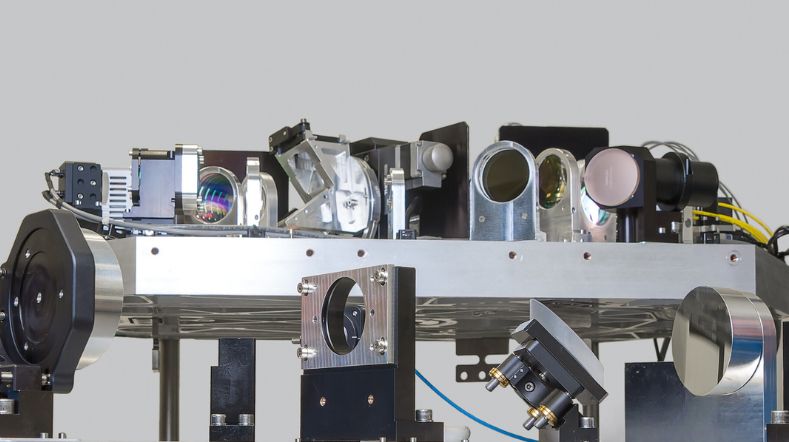

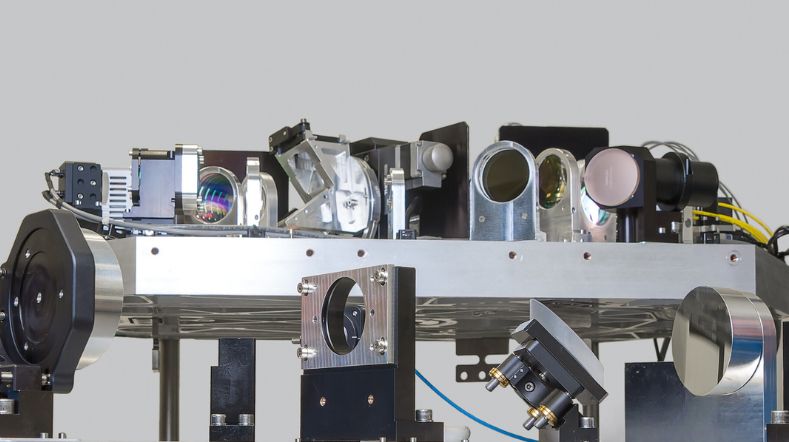

State-of-the-art facilities

From clean rooms with thermal vacuum chambers and space instrument calibration facilities to precision testing facilities, TNO Space systems engineering has in-house capabilities to design, test, and build the most advanced optical and optomechatronic hardware available.

Far more than just research and concept development, we have the multidisciplinary, independent expertise to also design and build fully functioning systems. We enable the precision mechanical engineering of complex mechanical systems and validate those systems’ performance through testing and measuring. Our facilities include:

- Well-equipped, modern work- and model shop.

- Precision cleaning and bonding facility.

- Precision (free form) mirror manufacturing facility with single point diamond turning capabilities.

- Facilities to develop and produce special optical coatings.

Want to learn more about what the TNO Space systems engineering team can do for you? Contact us today to explore the possibilities.

Precision air quality monitoring

From TROPOMI to TANGO to Sentinel-5, Space systems engineering has coordinated and enabled TNO’s contributions to the most important air quality and pollution observation systems of our time. These innovations not only mark our advancements in research and innovation, but our commitment to societal benefit.

Satellite-based communication

The ever-growing amount of data transfer is swiftly overloading traditional radio-frequency systems. TNO Space systems engineering enables a variety of projects related to laser satellite communication by coordinating efforts to increase bandwidth in a secure and stable way.

Insight into the universe

Understanding the universe – and our place in it – is a fundamental scientific pursuit. TNO Space systems engineering coordinates and qualifies projects that enable ground-based astronomy instruments to help us gain deeper insight into our planet and those around us.

Get inspired

Time setter story: Max van Strien

TNO technology selected for Secondary Mirror of W. M. Keck Observatory

Time setter story: Benjamin Brenny

Optics

Laser projection systems