TNO innovation offers discarded wind turbine blades a circular future

Wind energy is gaining momentum. In Europe alone, there’ll be offshore wind turbines producing around 135 gigawatts of power by 2030. The downside is that blades will end up on the scrap heap or be incinerated at the end of their 25-year lifespan. In Europe, some 60,000 tonnes of composite blade waste is already at stake in 2025, rising to more than 800,000 tonnes in 2050. TNO is well advanced with a promising solution. In Europe, this results in some 4 million tonnes of waste every year. TNO has now taken a promising solution to an advanced stage.

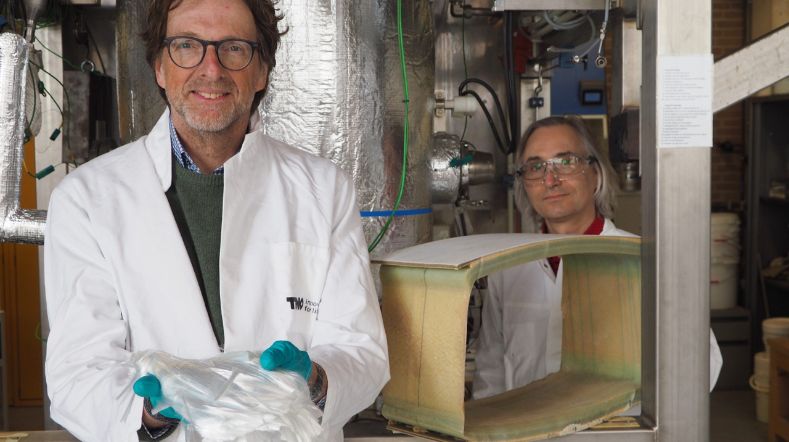

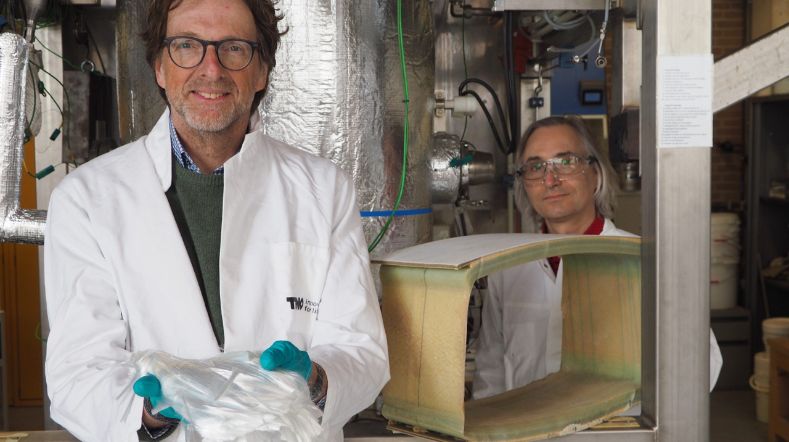

‘It’s also badly needed,’ says Harald van der Mijle Meijer, Senior Consultant for Wind Energy Technology at TNO. ‘Not only do we need to get rid of the huge pile of turbine blades that are now being buried or incinerated, but governments are imposing increasingly stringent requirements on wind farm builders and owners. Companies bidding for tenders to build offshore wind farms in many countries must be able to demonstrate that the wind turbines are largely recyclable. Most components, such as the foundation and the tower, can already be recycled, but there’s no commercially attractive solution yet for the blades. That’s what we’re working on at TNO in collaboration with Brightlands Materials Center, an initiative of TNO and the Province of Limburg, which specialises in developing sustainable materials.’

Unique method

It involves a unique method for extracting the fibres from the turbine blade and reusing them in new products. Current blades are more than 50% glass and carbon fibre, which are in principle suitable for reuse. There are several sustainable options for the blades at the end of their service life. Mechanical or chemical recycling has drawbacks as regards quality and scaling up. The experts at TNO and Brightlands Materials Center have therefore focused on a thermochemical process involving pyrolysis, in which the material is heated to almost 500 oC without oxygen, releasing the fibres. They can then be processed into thermoplastic composite to be used in recyclable products. This method provides the best outcomes for reusing the recycled material again and again.

‘It provides two solutions for the price of one, as you solve a waste problem and also offer recycled material to manufacturers in a variety of sectors.’

Two solutions for the price of one

TNO Business Development Manager Richard Janssen works at Brightlands Materials Center: ‘We work here with a group of researchers on the development and innovation of polymeric materials, in this case thermoplastic composites. These consist of plastic and fibres, which makes them extra strong. You therefore see them in ever more products, from car parts to sporting goods. Wind turbine blades also consist of composites, but a different type: thermoset composites. They also contain fibres, but a different type of plastic that hardens during production and is very difficult to recycle. Pyrolysis is a solution to this problem, allowing the fibres to be recovered. We then use these fibres in the easier-to-recycle thermoplastic composites, making it simpler to take them apart after use.

Composite is as strong as metal but much lighter in weight. We develop technologies here not only to make thermoplastic composites, but also to recycle them. You want them to be circular and to be used in a variety of products for as long as possible. It provides two solutions for the price of one, as you solve a waste problem and also offer recycled material to manufacturers in a variety of sectors. They then don’t have to use raw materials for their products.’

Scaling up

Mariusz Cieplik, Senior Scientist Materials at TNO, specialising in pyrolysis: ‘This is an extension of a technology we developed previously to produce biochar, a soil improver that we make from biomass by means of pyrolysis. We’re now making that process suitable for recycling wind turbine blades. There are strong similarities between the two processes. In both cases, the aim is to separate fully what is released during pyrolysis from the solids that remain. The technology has since outgrown the lab. We now have a pilot plant that can make biochar on a scale of a few tonnes. And we’ve successfully replicated that process for turbine blade recycling.

With TNO, we now have a perfect platform to build on. If we can scale this up to industrial level over the next few years, we’ll have a unique recycling process that will save a lot of waste and reduce the use of raw materials, because the material we recover will be given a new life in another, high-quality product.’

‘Our innovative process enables us to add value on two sides. The material we extract from the blades can be used in many high-value products, such as car parts, furniture, packaging, smartphones – too many to mention.’

Bringing two worlds together

Harald: ‘We make this attractive to all the parties in the supply chain. Manufacturers in various sectors, for example the automotive industry, are increasingly under legal obligations to use recycled materials in their products. And the wind energy industry has a waste problem. We bring those two worlds together. Our innovative process enables us to add value on two sides. The material we extract from the blades can be used in many high-value products, such as car parts, furniture, packaging, smartphones – too many to mention.’

Richard: ‘It could be a solution for both the material transition and the energy transition. During the production of wind turbine blades, manufacturers never properly considered the end of their service life. The blades had to make money, be strong and safe, and withstand extreme weather conditions. Recycling was never really on the agenda. Now we’re investigating how to keep the fibres from blades in use for as long as possible. If these fibres are no longer usable in one application, such as turbine blades, you process them again in the next application. That way, you delay incineration for as long as possible.’

Organising supply chains

In a few years’ time, blade recycling should be carried out at a number of locations around the country, preferably near major ports where the blades are brought in from sea or land. Hubs will then be set up there to turn the discarded blades into high-quality semi-finished or finished products. TNO is discussing this at European level with industry, governments, and knowledge partners, with the aim of organising it on a large scale.

Get inspired

Improving wind turbine maintenance with the sensor installation robot

Project launched for recycling wind turbine blades

TNO research leads to better damage prediction for offshore wind turbine blades

Better damage prediction for wind turbine blades through unique weather measurements at sea

First study on public perception of wind turbine circularity