DME: Sustainable gas helps businesses move away from fossil fuels

Dimethyl ether (DME) today is widely used in the industrial and chemical sector, for example as a propellant in paints and hairspray, but moving forward the molecule has the potential to decarbonise the hard-to-treat off-grid energy sector. In Europe alone, that’s a huge market. TNO has developed a method to produce DME very efficiently and cheaply from CO2: a major step from fossil to renewable, and to making carbon circular and making the industry and society sustainable.

The advantages of DME

When produced from sustainable feedstocks, renewable and recycled carbon DME has a GHG footprint significantly lower than LPG and high-carbon fossil fuels such as heating oil and coal. It can be used on its own or blended with LPG to reduce emissions for homes, businesses and industry which are not connected to the gas grid. In Europe alone, that’s a huge market – around 20M tonnes/year of LPG is used in Europe for energy applications.

From fossil to circular carbon

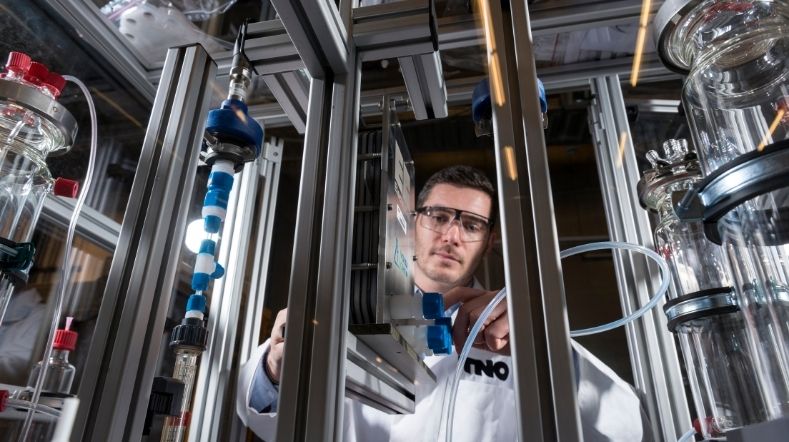

One of the technologies developed by TNO is SEDMES (Sorption Enhanced DME Synthesis), which allows CO2 and hydrogen – preferably green hydrogen – to be converted into DME in one step. The CO2 can be captured directly from outdoor air or from biogenic waste streams on companies’ sites, after which it is converted with great efficiency.

The traditional conversion method is limited by being an equilibrium reaction. One-step conversion is possible but provides an energy yield of at most 10%. Because water is removed by adsorption during SEDMES, the process achieves an energy yield of up to 85%. The result is a robust one-step process, immediately providing a much purer product and maximum energy yield. TNO has now built a mobile pilot unit to demonstrate this technology.

Webinar: CO2 reduction and green carbon in the industry from residual flows

Sign up for the webinar on 21 June 2023 where TNO experts will present three unique technologies that convert carbon en CO2 into sustainable products.

A billion people off-grid

The pilot project caught the attention of Dimeta, a joint venture established in 2022 between Dutch company SHV Energy and UGI International, two of the largest global distributors of LPG. Dimeta aims for the large-scale production of renewable and recycled carbon DME to accelerate the decarbonisation of the off-grid energy sector.

Over a billion people across the world live in homes not connected to mains gas – they are ‘off-grid’. Often relying on high-carbon fuels, oil or coal, these homes are typically less efficient and harder to retrofit, particularly older, traditional properties or those in remote areas. These buildings do not lend themselves to full electrification, solutions such as heat pumps practically challenging or unaffordable for many rural homes. It is for these homes, the transition to renewable liquid gases, such as renewable & recycled DME, offer a just transition to Net Zero.

DME is an alternative fuel that can have significantly lower carbon emissions than conventional fossil fuels, and can be used in existing LPG infrastructure enabling fast and cost-effective roll-out to the many different sectors that rely on LPG today.

Collaboration and joint innovation

Dimeta and TNO work together in several projects for upscaling sustainable technologies on industrial scale and for the production of advanced biofuels and renewable fuels of non-biological origin. As part of the BUTTERFLY consortium, to demonstrate flexible, efficient and low-cost production of renewable DME and synthetic natural gas. In the POWERED consortium, to develop technology for the production of DME from wind energy and other renewable energy sources.

“The TNO SEDMES technology is a really exciting next step in the scale-up of renewable and recycled carbon DME. Dimeta aim to secure around 300,000 tonnes of per year by 2027. We are building a plant in the UK that will be operational in 2025 and there are plans for production in the US.”

Key link in decarbonisation

‘The TNO SEDMES technology is a really exciting next step in the scale-up of renewable and recycled carbon DME’ says Lizzie German, Investment and Technology Manager at Dimeta. Dimeta aim to secure around 300,000 tonnes of per year by 2027. “We’re developing a commercial renewable and recycled carbon DME plant in the UK, targeting start-up in 2025, and have begun the development of further plants in the US and Europe.

There’s a great need to reduce greenhouse gas emissions from the off-grid heating and industrial sectors, and renewable and recycled carbon DME can make a significant contribution to this by being used in households, farms, industry, and transport. In Europe, it’s a clean replacement for widely used propane and butane. The technology TNO is developing could expand the scope of available feedstocks and improve the efficiency, cost and GHG emissions of the DME production process.’

Efficient and cheap

Expert Jan-Willem Könemann of TNO foresees DME taking off in the coming years, especially now it has been shown to be efficient and relatively cheap to produce.

‘The key issue in meeting climate goals is always to achieve both the use of sustainable energy and reuse of raw materials. DME is a very good fit in this context with its SEDMES technology. We have to move away from fossil fuels but the question is then how do we continue to make all those products that are traditionally carbon-based? You quickly find yourself looking at the combination of CO2 and hydrogen.

“In our process, we turn CO2 into sustainable DME. Combustion of DME in turn produces water and CO2. In this way, you can capture CO2, keep it circulating, and make new raw materials. While DME is currently still something of a niche product, it could play a major role in the energy transition.”

More applications

“There are many more products and applications that can be imagined with DME. It can replace diesel and LPG, but it can also serve as a building block for many valuable chemicals that are now fossil-based. DME can be further dewatered to ethylene, a feedstock for many materials we use in our daily lives. If we run out of fossil carbon sources for our products over time, we’ll definitely have to concentrate our efforts on CO2 as a feedstock for DME. At TNO, we’re constantly working to improve the technologies needed for this,’ says Jan-Willem Könemann.”

Get inspired

Scaling-up electrochemical technologies for renewable ethylene production

CO2 infrastructure and transport

Carbyon: the TNO spin-off innovating in CO2 filtration technology

TNO’s next generation biorefinery accelerates material transition

Port of Rotterdam as a key European hub for sustainable carbon