Ten things to know about carbon capture and storage (CCS)

Carbon capture and storage is unavoidable if we are to meet climate targets. For now, the bulk of energy in the Netherlands comes from coal, oil, and gas, which cause CO2 emissions. What about carbon capture and storage? Where do you capture CO2, where do you store it, and how does that work? We explain this process below.

1. What problem do we solve with carbon capture and storage?

We can solve the problem of climate change – to a not insignificant extent, that is. For a sustainable energy system alone, carbon capture and storage (CCS) is not really needed. But the greenhouse gas CO2 is a cause of global warming. Because we need to prevent further climate change as much as possible and reduce CO2 emissions as quickly as possible, we cannot escape CCS. We will still be dependent on fossil fuels for our energy supply for a long time to come, despite global efforts, not least by TNO, to find sustainable alternatives. CCS leads fairly quickly to major reductions in carbon emissions, in particular from energy-intensive industry and power plants.

2. How does carbon capture work?

Roughly speaking, there are two ways of doing this. The most common is carbon capture ‘at the smokestack’, i.e. at the end of an industrial process, which is called post-combustion. You capture the carbon from flue gases after burning gas, coal, or waste. But at TNO, we are also developing methods to remove CO2 early in the process (pre-combustion). A third way is to remove the CO2 present in the atmosphere using special technologies (direct air capture).

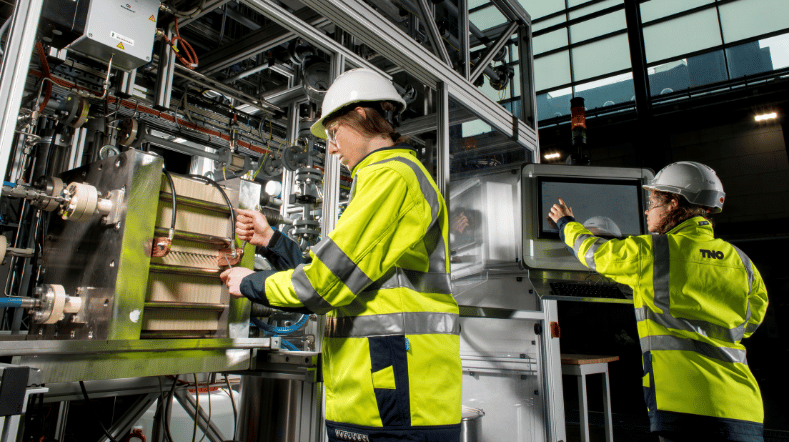

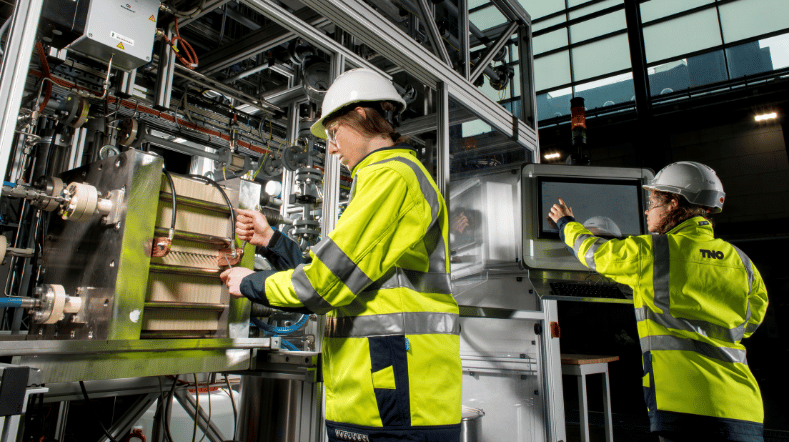

SEWGS: revolutionary CO2 capture technology

To make existing industrial production processes cleaner, TNO has developed a technology that captures CO2 very efficiently while producing hydrogen.

3. Apart from CCS, there is also CCUS.

It stands for Carbon Capture, Utilisation and Storage (CCUS), and there is even CCTUS. The ‘U’ therefore stands for utilisation, or the reuse of CO2, while the ‘T’ stands for transport from the place where you capture the carbon to underground storage or a facility where you will do something else with it. This is because you can also convert CO2 into valuable chemical building blocks from which you can make other products, such as electric fuels (e-fuels). Unlike CCS, CCU does not lead to emission reductions per se, except that it replaces fossil fuels to some extent. Reuse of CO2 is very likely to be deployed on a much smaller scale than CCS.

4. Why should carbon be stored?

Because we need to isolate CO2 permanently from the atmosphere. Emission reductions involve huge amounts – tens of millions of tonnes annually in the Netherlands alone and hundreds of millions of tonnes each year for Europe. After carbon capture, underground storage is the only option, and at such volumes, salt caverns are completely inadequate. We are therefore mainly considering depleted gas fields and, to a limited extent, saline aquifers.

Carbon caputure storage: a key technology in energy transition?

Carbon capture and storage is a pivotal technology in the energy transition. In the podcast episode ‘Increasing our understanding of carbon capture and storage technologies’ of ‘The World We Want’ Filip Neele lead scientist at TNO discusses CCS technology and its role in supporting global sustainability.

5. Where can we store carbon?

In the Dutch North Sea region, there is storage capacity for hundreds of megatonnes (millions of tonnes) in depleted gas fields. We therefore have many times the storage capacity of what we emit annually in our country. Countries such as Norway, Denmark, and the UK are also looking at storage, especially in aquifers. We could perhaps investigate in the Netherlands whether we have aquifers offshore that could be of interest. For the time being, our focus is on depleted gas fields, as in the Porthos project, which is a collaboration between the Port of Rotterdam Authority, Gasunie, and Netherlands Energy Management (EBN). TNO is conducting substantial supporting research for this purpose.

6. Besides offshore, is carbon storage possible in land-based depleted gas fields?

Technically, this would be possible, as well as in salt caverns and aquifers, which are also being looked at for hydrogen storage. However, previous pilot projects met with public resistance, and because storage capacity under the North Sea is more than sufficient, the main attention is to fields under the sea.

7. Are there any risks involved?

Storage in depleted gas fields has the advantage that the storage itself has been proven to be safe. Globally accumulated experience of storage in saline aquifers shows that this is also a safe method of storage. TNO has conducted extensive research into carbon storage in depleted gas fields under the North Sea and concluded that it can be done safely. However, it is important to permanently monitor how CO2 will behave there under pressure. TNO has the expertise to do this.

8. When will carbon capture and storage be operational in the Netherlands?

The first major project, Porthos (Port of Rotterdam CO2 Transport Hub and Offshore Storage) was given the green light in the third quarter of 2023. This will enable the necessary infrastructure to be built to transport carbon captured from industry in the Port of Rotterdam to some gas fields more than three kilometres under the North Sea. This is a huge project even by European standards, which will capture and store 2.5 megatonnes per year. Over a 15-year period, that will total just under 40 megatonnes of CO2. Porthos is expected to be operational in 2026.

An even bigger CCS project in the pipeline is Aramis. This will build further on the infrastructure of Porthos and will also enable transport of CO2 by ships to Rotterdam, where the Aramis pipeline begins. Over the long term, this will amount to 22 megatonnes annually, which will also be stored offshore in depleted gas fields. Final decisions on this project will be taken in 2024.

9. What is TNO’s role in carbon capture, transport, and storage?

TNO’s role in capture, transport, and storage, in a nutshell, is that we conduct supporting research to make CCS faster, better, more efficient, and cheaper. We are also facilitating the rollout elsewhere in Europe. TNO is a research institution at the forefront of this field. We deploy our knowledge nationally and internationally to improve and accelerate CCS development. In projects such as Porthos and Aramis, we are gaining a wealth of knowledge that is needed internationally. The Netherlands is in a position to become a driver in this field. Soon, we will also be able to make connections with neighbouring countries that do not have storage capacity of their own.

10. What has TNO contributed to carbon reutilisation in recent years?

The ability to capture carbon from AVR’s waste-to-energy plant on a very large scale. This reduces carbon emissions by 50,000 tonnes a year. Horticulturalists use the CO2 to increase crop yields.

We devised and built a mobile carbon capture pilot plant for on-site testing of carbon capture from various flue gases. In this way, we help companies reduce their emissions and discover what is technically feasible and economically viable. The mobile plant has also been used at AVR.

We developed the SEWGS separation technology, which was the first to be successfully used by Swedish steelmaker SSAB. This technology captures carbon during the production process and produces hydrogen at the same time.

The SEDMES technology converts captured carbon together with green hydrogen into useful by-products, chemicals, and fuels.

Biomass plays a prominent role in the transition to sustainability. It is preferably used where sustainable alternatives are available only in limited quantities or not at all, as a high-quality feedstock for the bio-based economy; as a fuel for process heat in industry; for aviation, shipping, and heavy road transport; and also as a back-up or to absorb peaks in space heating and electricity generation. Moreover, the use of biomass offers the possibility of negative carbon emissions.

CO2 electrolysis is a promising electrochemical technology to convert this greenhouse gas into high-quality sustainable chemicals. We have built a pilot plant, ZEUS, where researchers and industry can collaborate with us to take CO2 electrolysis to the next level. It is the largest independent CO2 electrolysis plant in Europe.

Plasma technology has the potential to play an important role in meeting climate goals. It enables hydrogen to be made from methane CO2-free, while also producing valuable hydrocarbons. These hydrocarbons can then be used to produce sustainable raw materials. After successful trials in the lab, construction of a pilot plant will start in 2025. The technology should be rolled out commercially by 2030.

Underground carbon storage requires a study of the manner in which CO2 can be safely transported in subsea pipelines and pumped into gas fields using injection wells. TNO collaborated on the design of the transport and storage system for the Porthos project and identified storage risks.

TNO is developing a test facility to investigate the behaviour of CO2 during transport, injection, and storage. The facility is a tool for the Netherlands to address technical issues from projects such as Porthos and Aramis, for example, and will also be used in the context of European research projects on CCS.

Get inspired

CO2 storage

Unique test installation for CO2 capture and conversion to green chemicals

SEWGS: revolutionary CO2-reduction technology

Capturing carbon emissions

Award-winning excellence: CO2 capture applied