Time setters: Personalised medicine made with the 3D printer

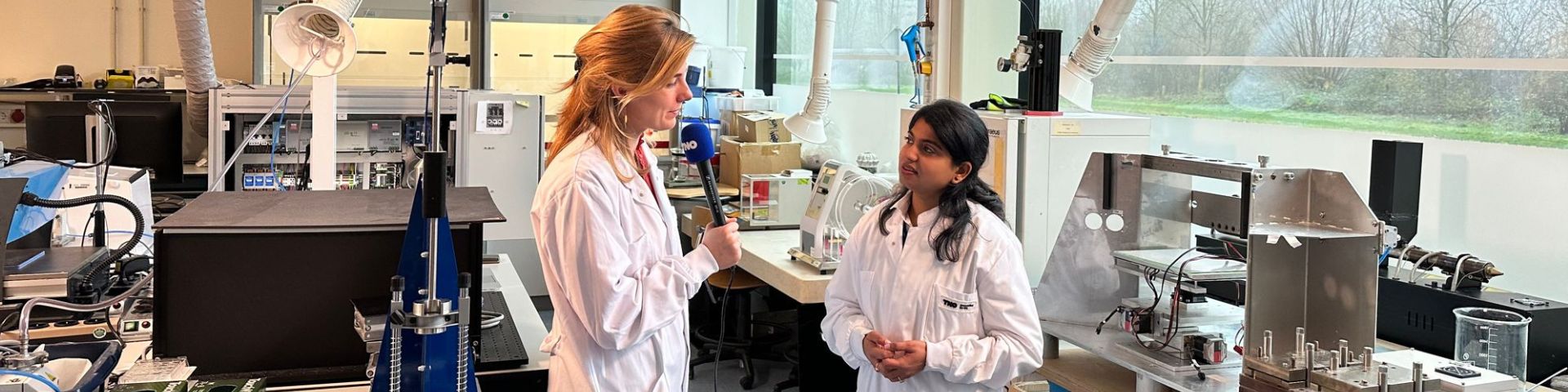

At TNO, we make a mark on our time. In this series, you will meet the TNO’er behind the innovation; the timesetter. What exactly do they do and how are they solving the challenges of our time? In this episode, we talk to time setter Jayeeta Sengupta, Program Manager and Senior Consultant 3D pharma printing, about how a special printer brings personalised medicine one step closer.

Every patient has a different body, weight and condition. Children for instance weigh a lot less than adults. And a baby is completely different from a teenager. Some can easily swallow a pill, while others cannot.

Pills on the other hand are widely produced in standard doses: 500 milligrams, 250 milligrams, you name it. Why not change that, says Jayeeta Sengupta, programme manager 3D printing food and pharma.

Pills with precise doses

Jayeeta is working on a machine that can 3D-print tablets exactly in the dose a patient needs. "A particular patient may need a dose of 125 milligrams, while the standard tablet consists of 500 milligrams. To give someone the right dose, such a tablet must then be broken into pieces or dissolved. It is trickier than you think to ensure that each piece of the broken tablet contains exactly the right dose," she explains.

Sengupta's team is developing a 3D-printer and manufacturing technique that allows you to print tablets in exactly the right dose for an individual.

"Personalised tablets are necessary to reduce side effects, especially in paediatrics. A tailor-made medicine guarantees that each patient gets exactly the amount that is safe and effective."

Free-form with function

The 3D-printer also offers other advantages. "We can shape tablets differently with it. Think of a tablet with narrower diameter, which is easier to swallow. Or a tablet that is perhaps differently shaped compared to the standard tablet shape: rolled up or with a ribbed surface. These dissolve slower or faster in the body, which affects the effect of the medicine. With the currently much used tablet compression method, you need moulds for every adjustment in design. With 3D printing, we are free in how to design the tablet.”’

Moreover, the printing process makes it possible to combine several drugs into one pill.

"This is obviously a game changer for elderly patients, who sometimes have to take as many as 10 or 15 pills a day. With the 3D-printer, that can be reduced to fewer numbers, just one or two so-called Polypills . That makes it easier not to forget medicines."

Want to know more?

If you want to know more about the 3D pharma printer, or are interested in a collaboration to bring this innovation to the market, get in touch.

Unique printer

TNO has used more than 30 years of 3D- printing experience to assemble this unique printer. Sengupta: "We are world leaders in food printing. All that knowledge and experience has helped us put together this extremely accurate pharma 3D- printer. There are only a few machines in the world that can achieve this level of precision."

Testing in 2024

Together with the Erasmus Medical Centre, the TNO team is conducting tests with this machine and optimising the formulation and the process. " This year, in 2024, we're aiming to produce the first tablets for patient use, which will undergo testing with patients. " says Sengupta.

"The drugs or active ingredients in these tablets are not new. We only work with approved medicine. We are specifically testing the production process, so how we make the tablet. That process has to meet all medical requirements, be efficient and effective."

As a significant milestone, the team has already demonstrated that the technology works and is currently busy in optimising the printing and related processes in hospital pharmacy setting along with Erasmus MC. With this step, we are one more step closer to have this technology available for personalisation of medication. "Personalised medicine for everyone – that reality is still far in the future. With this innovation, we want to bring that future a lot closer."

Become a time setter at TNO

Would you like to work on innovations that you can really use to create the future? If so, become a time setter like all TNO employees and make your mark on our time.

Get inspired

Developing accurate and inclusive medical devices

3D printed food: the future of personalised nutrition

Preclinical ADME

TNO develops ultrasound patch for organ monitoring

TNO launches Peregrion to boost market impact of its technology that accelerates medicine development