CEYAS as easy and affordable solution for yard automation

With driver shortages on the rise and a growing need for higher efficiency, yard automation is becoming an increasingly attractive solution to the logistics sector. The Cost Efficient Yard Automation Solution (CEYAS) offers an affordable, scalable, and reliable automation concept for distribution centres, ports, and other industrial applications. Partners Verhagen Leiden, V-Tron, and TNO demonstrated the potential of CEYAS in a successful demo. Now an end user is being sought to bring the product to market.

More and more Dutch companies are facing a shortage of drivers ‒ especially for repetitive operations such as shunting, loading, and unloading at distribution centres, in ports, and on industrial estates. This is not the only challenge in logistics, argues Jorn Gijsbers, Business Development Smart Vehicles at TNO.

‘The growth of e-commerce will put further pressure on the logistics chain over the coming years, increasing the need for efficiency. Yard automation will allow us to perform the same operation flawlessly and safely 100 times over, making the logistics process more stable, predictable, and manageable. This offers great savings potential for companies. With CEYAS, we want to demonstrate that automation can be deployed in a cost-effective and scalable way in simple use cases.’

A single operator for multiple trailers

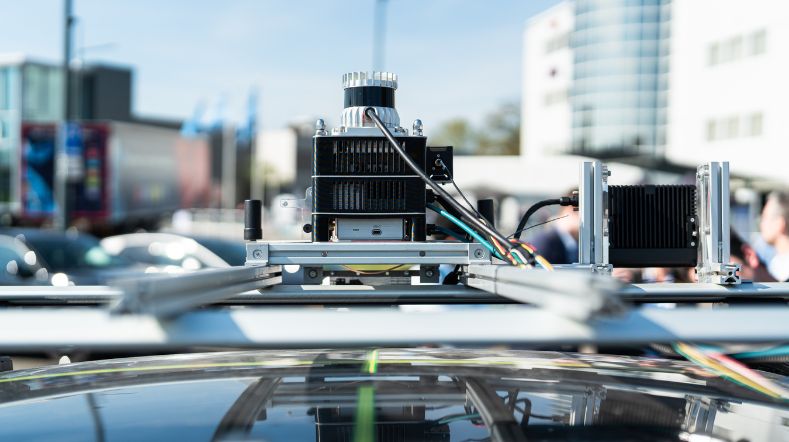

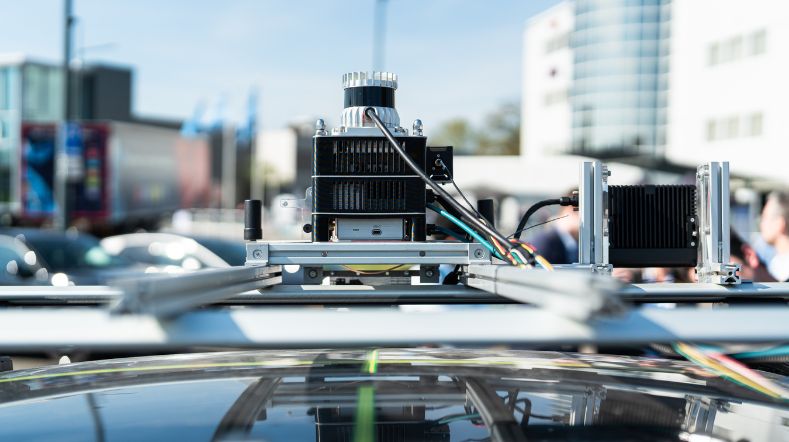

CEYAS is a vehicle-independent automation concept that automates repetitive operations at yards. It was first demonstrated at Automotive Week in April 2023, where TNO used the automated driving technology developed with major OEMs for the first time on an electric trailer mover: Verhagen Leiden’s V-Move. Thanks in part to an angle sensor from WENOVA.EU, the trailer managed to complete a challenging test course automatically.

The V-Move is capable of moving standard trailers in enclosed areas, such as when loading, unloading, parking, or electric charging. An operator oversees the movements and can take control if necessary. Because a single operator can operate multiple V-Moves, employee productivity is boosted and logistics movements are made safer and faster.

What is more, the trailer operator does not need to have a driving licence to operate the system, which lowers the qualification requirement. The concept is also scalable, as the trailer does not need to be modified. Finally, the trailer movers are operated electrically, reducing the yard’s environmental footprint.

‘In the use cases envisaged by TNO, the V-Move can be operated either manually or automatically, all done from the control tower that has been added.’

Substantial further development

Following the initial demonstration, CEYAS has been developed further by the innovation partners, says Ron Wouters, Senior System Engineer at TNO. ‘Since the first demonstration, we’ve made a number of reliability and safety improvements. In the use cases envisaged by TNO, the V-Move can be operated either manually or automatically, all done from the control tower that has been added. This consists of two screens: one for remote operation and another for automated driving.’

‘The remote operation system is a tried-and-tested development by partner V-Tron. In automatic mode, the V-Move follows a pre-programmed route. Moreover, we’re now using LiDAR technology for localisation, which works much more reliably in a built-up environment than the GPS we previously used.’

Convincing demo

A year and a half after the first CEYAS demo, a second one took place at the Automotive Campus in Helmond in front of over 60 potential users and technology partners. They had the chance to see for themselves the added value that this form of yard automation can bring. The remote operator started by manoeuvring the V-Move under the trailer into the dock. Once coupled, the trailer mover travelled along a pre-programmed route across the shunting yard fully automatically. The V-Move performed a turning manoeuvre independently and proved itself capable of docking the trailer in a narrow doorway with great precision.

Wouters: ‘We can see in practice that there is a kind of an interaction between the automated driving and the remote operation. When approaching pedestrian crossings or performing special manoeuvres, for example, it may be safer to operate manually.’

‘We want to know what there’s a need for, and how the technology will eventually be integrated into a user’s logistics processes.’

Testing is crucial

Verhagen Leiden, V-Tron, and TNO have already taken the technology to a late stage of development. However, to get to an even higher technology readiness level (TRL), an end user is needed to step in, as Ron Wouters explains: ‘We could explore this concept a lot further – but to do this most effectively, we’d need to work closely with an end user as an innovation partner.

‘After all, we want to produce a solution that will actually be used. We want to know what there’s a need for, and how the technology will eventually be integrated into a user’s logistics processes. If you really want to add value, you need to embed technology in your logistics process. And you can only do that by testing that technology in real-life situations.’

Rick Verhagen of Verhagen Leiden agrees with Wouters. ‘Testing is who we are. We always want to deliver a solution that works in practice, so we often sell machines on a ‘no cure, no pay’ basis. Of course, it would be nice if a client purchased 50 trailer movers in one go – but I’d be equally happy to have a partner on board that wants just a single one, simply to build experience together.’

Learning by doing

What does the ideal innovation partner and use case look like? Jorn Gijsbers: ‘We’re looking for a partner that sees the problem for what it is and wants to work with us towards an innovative solution. A partner that understands that this technology is not completely ready yet, but is confident that something good will come out of it.’

‘In addition, the use case should be clear. I can see a lot of experiments with yard automation in the market that I think are too complex, such as in mixed-traffic situations. Let’s start with simple use cases. Learning by doing is very important at this stage. I can’t see anything that we can’t solve. I envisage us really working on a use case together with a partner on site. In that sense, it helps that TNO has specific knowledge of logistics processes.’

Gijsbers stresses that there is no time to lose and the time for action is now. ‘We need to get going. The Netherlands won’t be able to remain an important logistics hub in the future without some form of yard automation. Eventually, this will become part of a highly automated chain – but the place to start is in the yard, which is where the biggest gains can be made in the short term. Of course, you have to be willing to invest to be among the frontrunners, but that lead will be worth a lot in the end. Of that I’m sure.’

Get inspired

How is YER award winner Chris van der Ploeg doing?

TNO launches Motion Comfort Institute for automated vehicle era

Releasing autonomous software faster with DeepScenario and TNO’s StreetWise

MARQ opens its doors: a place to collaborate on the mobility of the future

Demonstrations of automated driving and charging for logistics at Maasvlakte