How is plastic recycled?

There is a strong recycling culture particularly when it comes to paper, glass and metal. Yet the majority of plastic waste still goes straight into incinerators or landfill. At TNO, we develop advanced technologies to extract materials from waste and convert these into new raw materials suitable for numerous applications. But what are the different recycling technologies, and which are the best under which conditions?

Which recycling technology should be used when?

It all depends on the type and quality (cleanliness, mono or multi-material, etc.) of the plastics entering the recycling stream. The higher the quality of the sorted waste (mono-material and free from contaminants), the more cost-effective and easier it is to recycle. In addition, there are various drivers from a systems perspective of influence like application, logistics and regulations.

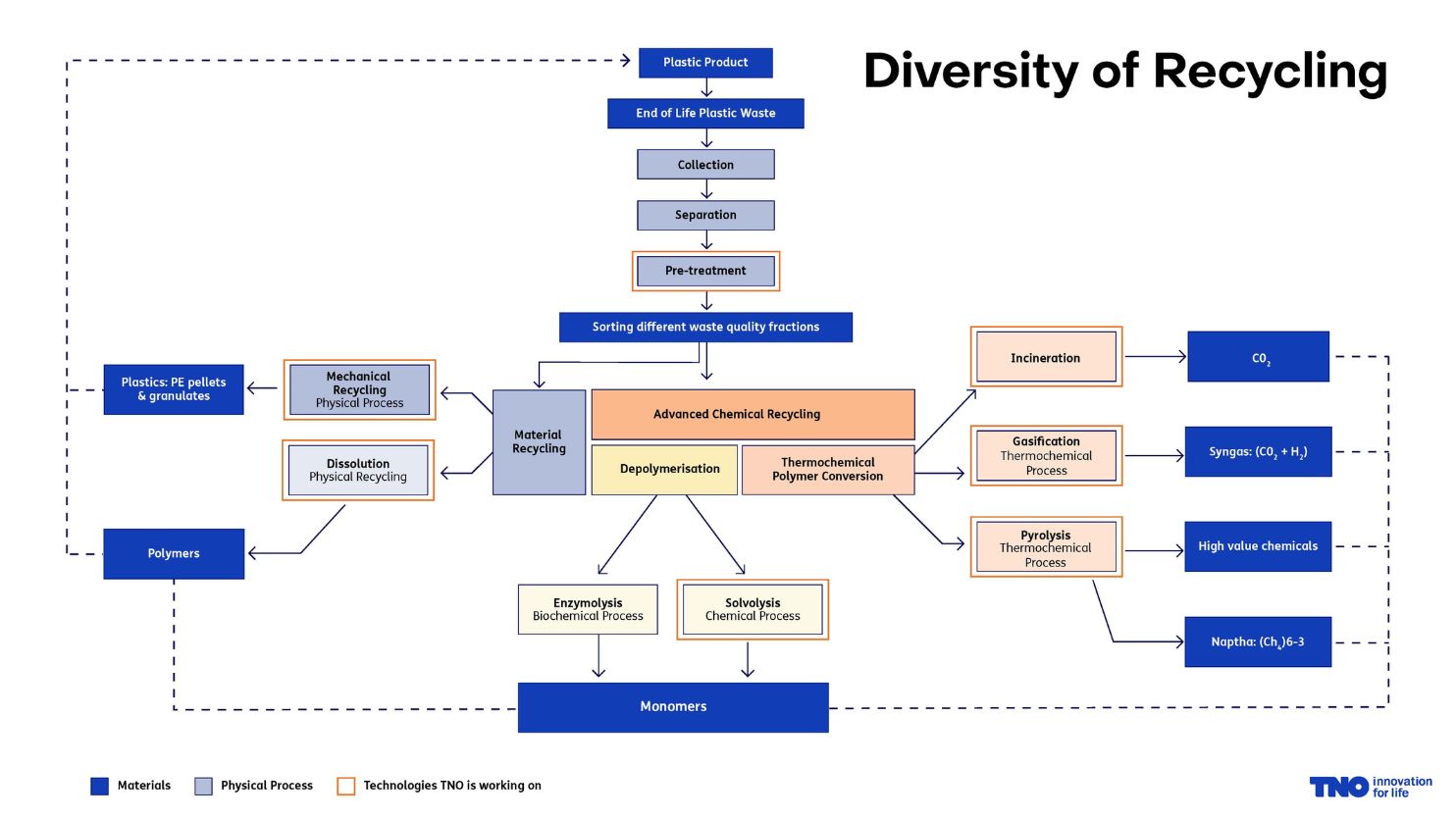

We’ve compiled an overview of the most important details of the different stages and recycle technologies into an infographic (pdf, 850 kB).

This diagram shows a product goes through once it entered its end of life phase. It describes the materials that result from recycling technologies and are suitable to make new plastics from. Thus closing the loop. It marks the technologies we work with at TNO. It is based on a diagram produced by the NOVA Institute.

How it all starts: plastics in the waste stream

Recycling starts when a plastic product reaches the end of its life and is discarded as waste.

This waste is collected, e.g. from homes, schools, public areas and businesses, and is then sorted into various categories, to separate valuable materials like plastic from residue waste. Advanced technologies identify and sort the different materials.

Brightlands Circular Space, our cutting-edge AI-powered sorting facility, will serve as an international hub for far-reaching research on efficient sorting strategies. Construction of this hub commences by the end of 2024.

Meanwhile, the R&D Hub for plastic waste processing focuses its research on innovative sensing and sorting techniques to enhance the quality and quantity of recyclable waste.

Once sorted, plastic undergoes pretreatment, i.e. it is washed and cleaned to remove impurities. At TNO, we have introduced the pioneering Upwash system using hydrothermal pretreatment technology. This increases both the amount and the quality of recyclable material.

Next step: recycling technologies

Once collected, sorted and optionally washed, the plastic waste streams are ready for recycling. There is a vast range of methods available for recycling plastics, but these technologies can be broadly split into two categories: material recycling – which can be mechanical or physical (dissolution) – and chemical recycling.

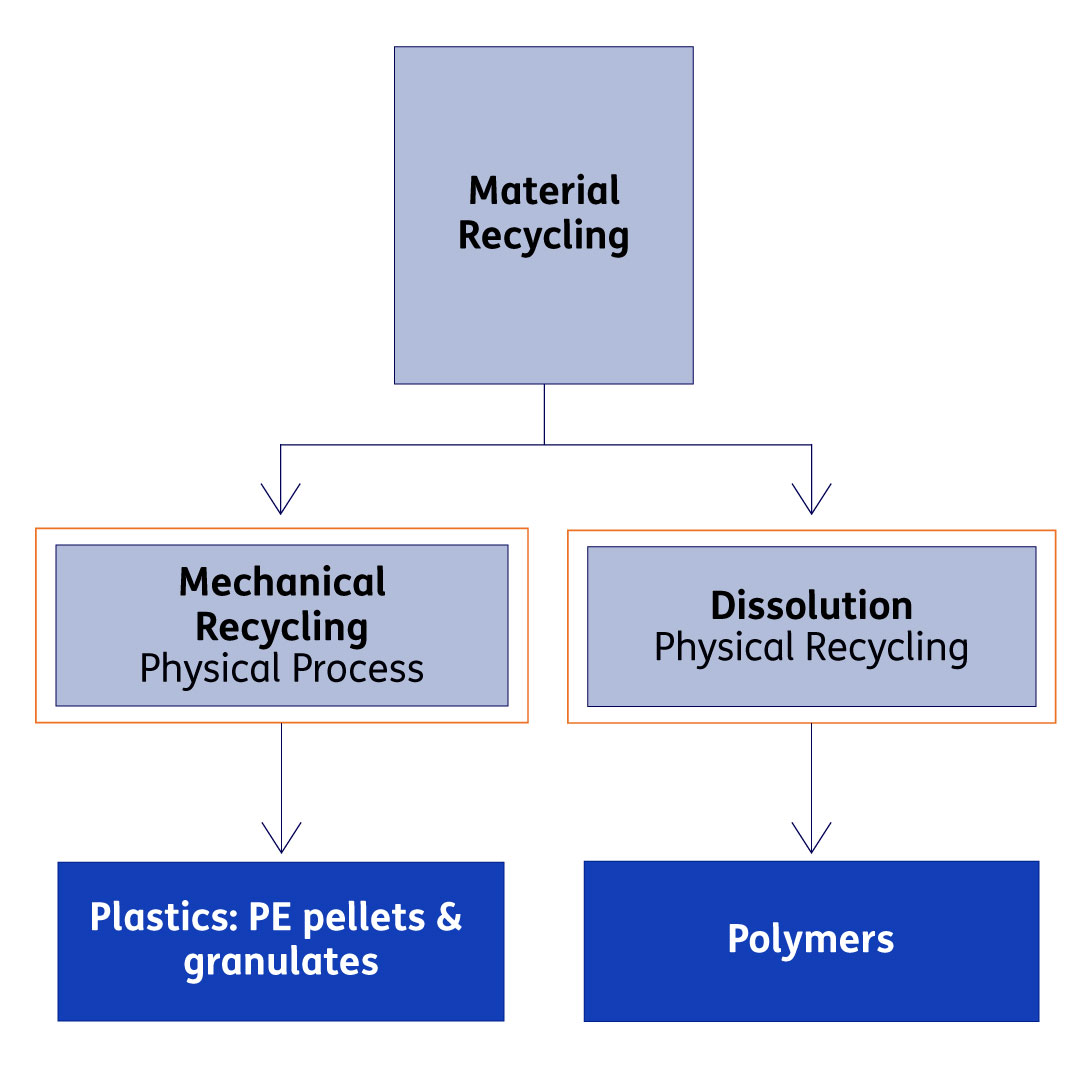

Material recycling

Material recycling is the most prevalent method for recycling plastics. When dealing with a relatively clean and well-sorted waste stream, this method is preferred due to its cost-effectiveness, lower environmental impact, and simplicity

As the illustration below shows, material recycling is split into two categories: mechanical recycling & dissolution. Both with a different output.

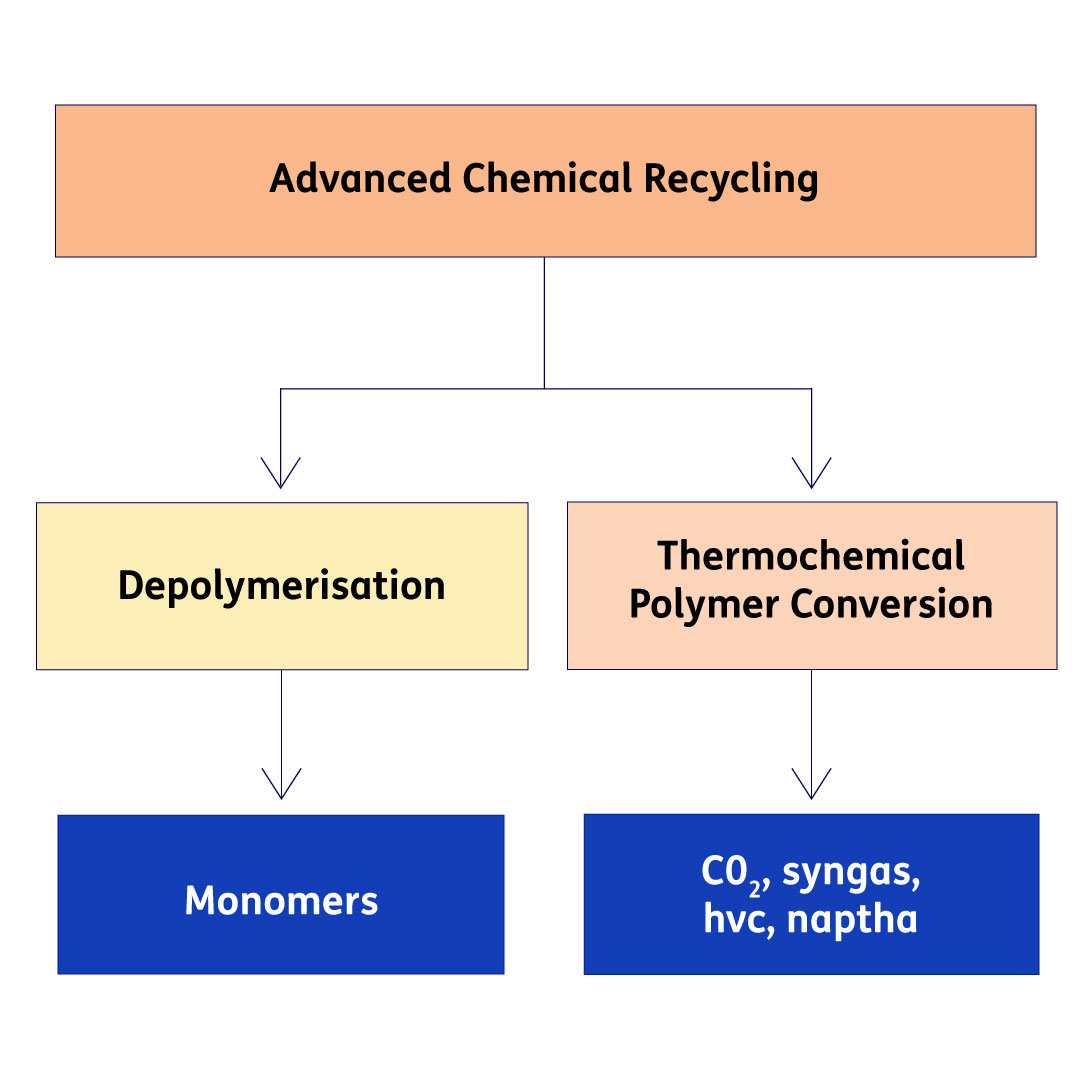

Chemical recycling

Mechanical and physical recycling are usually preferred but they cannot be applied infinitely. To fully recover the quality of the plastics, we can apply chemical recycling techniques.

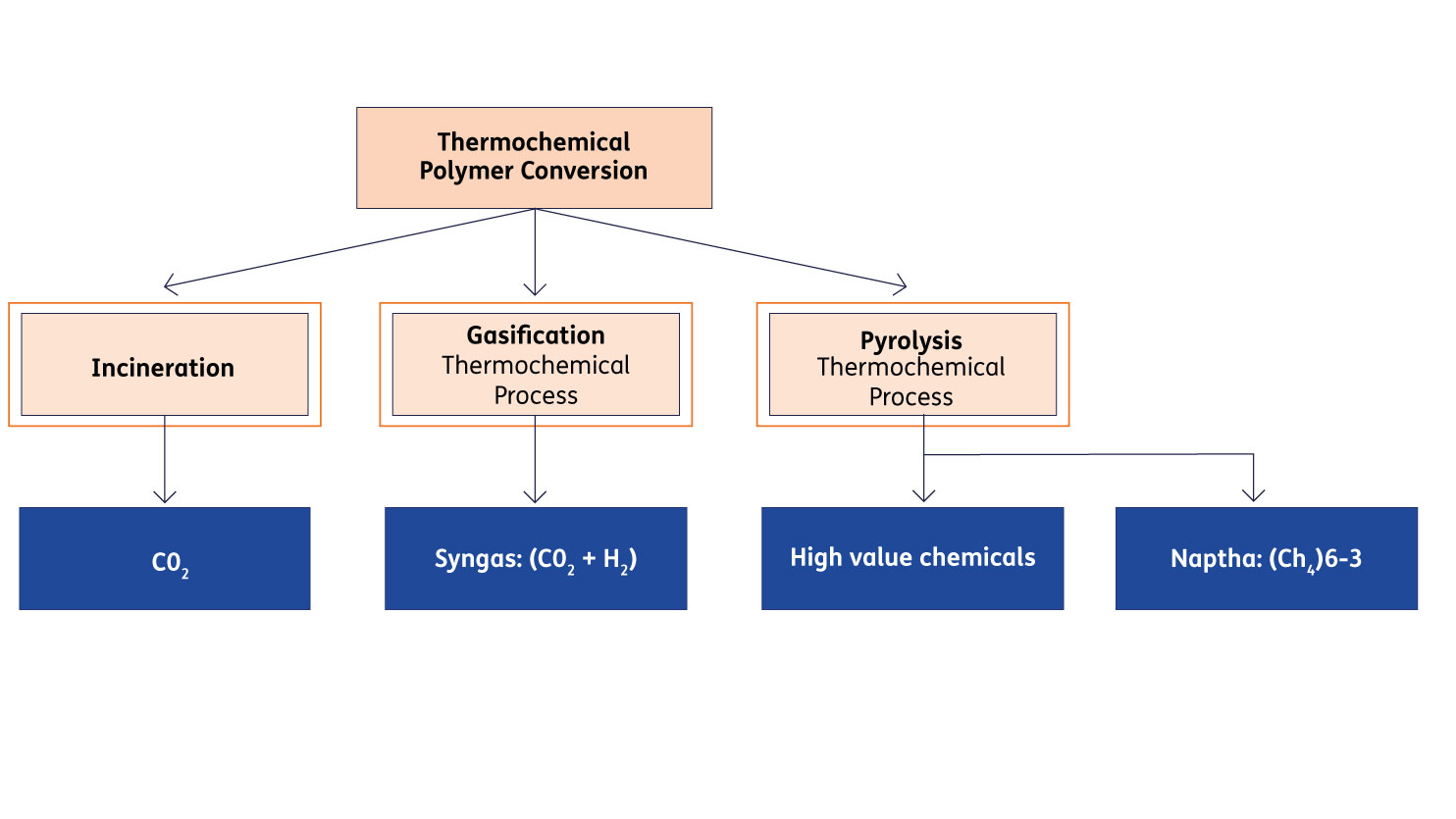

As the illustration below shows, there are various chemical recycling technologies. They are split into two categories: depolymerisation & thermochemical conversion. In both cases, the polymers are broken down into chemicals from which new polymers can be made.

Two types of material recycling explained

The most common plastic recycling method is mechanical recycling. If you have a relatively clean, well-sorted stream, this is the preferred option in terms of cost, impact and complexity.

It uses mechanical processes like washing, grinding, melting and compounding. It does not significantly change the chemical structure of the material, so plastics like PET (polyethylene terephthalate), HDPE (high-density polyethylene) and PP can be reused directly. The downside of mechanical recycling is the presence of contaminants. In addition, recycling loops lower the quality of the products.

We develop novel strategies to mechanically recycle more challenging waste streams, such as composites from the automotive sector. Currently, thermal conversion techniques are widely used, resulting in low-quality glass or carbon fibres. At TNO (BMC) and within the R&D Hub for plastic waste processing, we set out to develop cost-effective technologies that preserve the quality of these complex materials and their components, including fibres and plastic material. This involves innovative separation, recycling and decompounding technologies.

Dissolution is a physical recycling method that dissolves only the desired polymer, and not the unwanted polymers, additives or contaminants.

Several dissolution technologies for plastics recycling have been developed on pilot and market scale. TNO have proven that with its Möbius technology high-quality polymers can be obtained and directly compounded into plastic products. It involves the selective dissolution of the target polymers using an organic solvent, and a combination of separation technologies (e.g. filtration, adsorption) to remove any contaminants, additives and undesired polymers. It delivers higher quality products than mechanical recycling and is more suitable for complex waste flows. However, the use and recovery of organic solvents typically result in higher processing costs.

Two types of chemical recycling explained

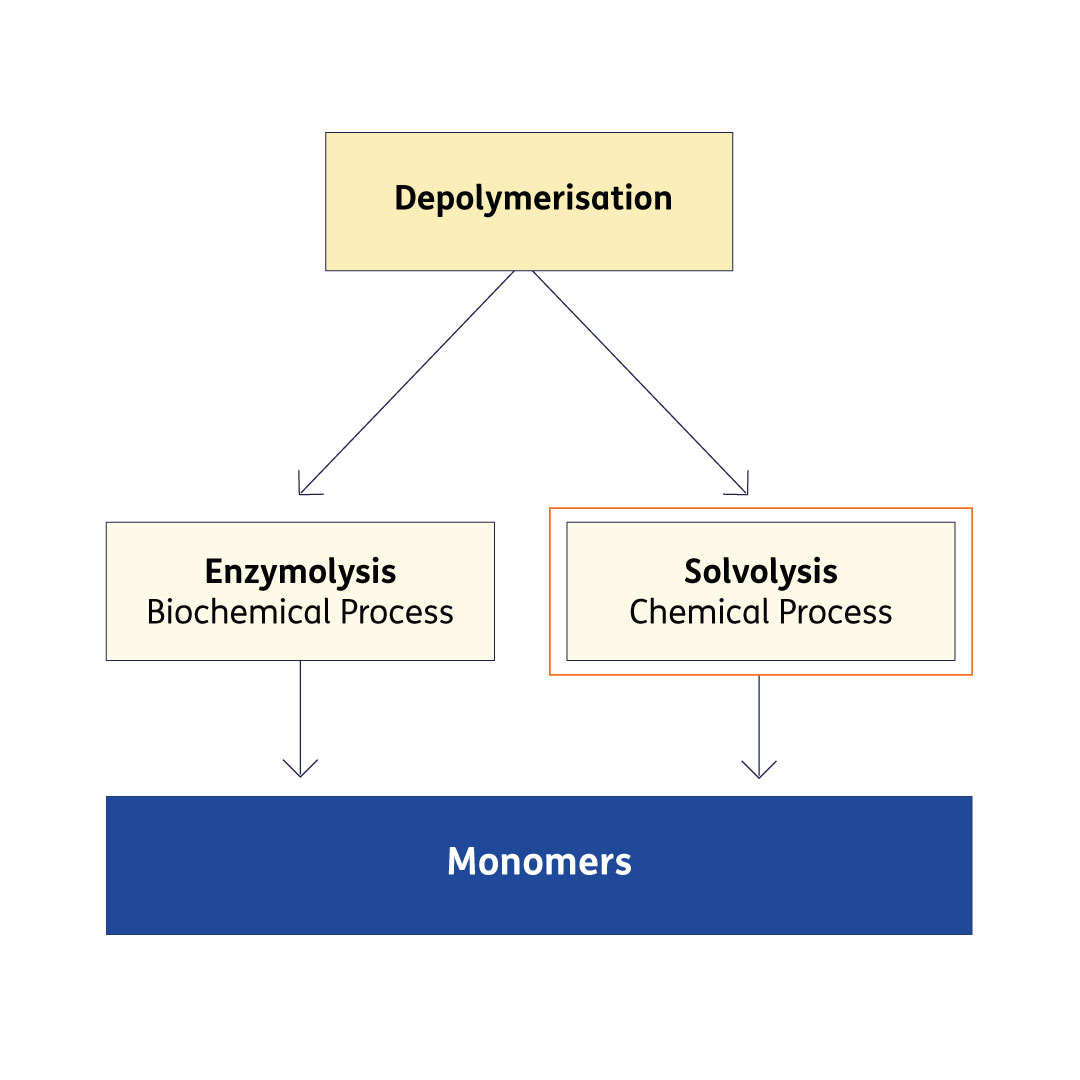

Depolymerisation is used when polymers are broken down into smaller units – the original building blocks:

- Enzymolysis (a biochemical process) involves the splitting or cleavage of a substance into smaller parts through the action of an enzyme.

- Solvolysis (a chemical process) involves a chemical reaction in which a solvent, such as water or alcohol, works as a reagent and is present in excess compared to the quantity required for the reaction itself. As a result of the chemical reaction, the polymer is split into smaller entities, either oligomers or monomers, the original building blocks.

After purification, both can be used to produce new polymers, with the same quality as virgin materials.

Thermochemical conversion is the breaking down of polymers at high-temperature, either in the absence or presence of oxygen. This produces an assortment of molecules that can be used in the petrochemical industry as the building blocks for chemicals, polymers and/or fuels.

Incineration combined with Carbon Capture and Utilisation (CCU);

Incineration combined with Carbon Capture and Utilisation (CCU);

Incineration should be used in combination with full heat integration and Carbon Capture and Utilisation for maximum circularity. TNO has developed various carbon capture and utilisation technologies to optimise the elimination of CO2 and the sequestration of carbon.

Gasification thermochemical process

Gasification is the most versatile solution for highly complex waste streams not suited to chemical recycling. This technology converts waste into syngas (CO+H2) using a limited amount of oxygen. Syngas is a very versatile raw material for a large variety of chemicals and fuels. TNO uses different technologies to convert syngas into highly valuable products> nog linken nieuwe.

Pyrolysis

One widely investigated technology is pyrolysis, in which plastics are heated in the absence of oxygen to crack the chains of polymers. The process yields a complex mixture of hydrocarbons in solid, liquid and/or gas form, depending on the conditions and the quality of the feedstock. Technologies vary depending on the input used and the products targeted.

Most pyrolysis technologies aim to convert polyolefin-rich waste into pyrolysis oil. After further treatment and separation, this oil (naphtha) can be used in a steam-cracking process to produce olefins, the building blocks for polymers.

In this field, many organizations explore the use of a catalyst. By using catalysts, milder conditions like a lower temperature can be used and more selective products are obtained.

Another example is the TNO Milena Technology , a thermal cracking technology that applies a higher temperature and a specially designed process. It produces a range of high-value chemicals such as olefins, BTX and syngas, depending on the composition of the waste input. Generally, thermal cracking can deal with much more contaminated waste streams compared to pyrolysis techniques. As such, cascading of technologies becomes a feasible option.

Which is the most sustainable, cost-effective and technically viable recycling option?

There are pros and cons to each technique. The most appropriate method for managing and recycling waste depends on the type and quality of the plastic waste in question.

To make a thorough comparison of recycling methods, we need to consider the complete cycle of each technology: how do we recycle something so that it can be reused as a raw material? A thorough comparison will take into account not only the technology itself, but also the sorting, washing and collection processes. We also need to assess the efficiency, energy consumption, robustness, the impact and costs of the processes. Only then can we decide which technology to use.

The best overall approach can be assessed using scenario models. These show how sorting, pre-treatment and recycling techniques affect quality, quantity, technical and economic aspects and the resulting environmental impact. One example is the TNO Plastic Recycling Impact Scenario Model.

The race to circularity is on

Technically, a circular plastics economy could be achievable by 2050. However, even before we think about recycling, we should consider other strategies on the R-ladder for increased plastic circularity.

And its success largely depends on the diligence of the business and political spheres. A relevant system needs to be established, including laws and regulations for end-of-waste status, the import and export of materials and incentives for investors. Clarity is key. Take, for example, the mandatory 30 percent share of recyclate in plastics, put forward by the Dutch Transition Agenda on Plastics.

The race to circularity is on, and we’re proud to be working with companies across the globe with a shared purpose. We can work together to build a sustainable future. Get in touch to find out how we can optimise your recycling process.

Get inspired

Collaboration for sustainability: better results through joint innovation

Webinar: Biobased plastics in a sustainable future

Biobased plastics

The challenge of choosing between sustainable materials for textiles

23 questions about biobased plastics in a sustainable society