How does the R-ladder lead us to a circular economy for plastic products?

Many people think of a circular economy in terms of recycling and reusing. But it means looking at waste differently, by giving value to products at every stage of the cycle. The R-ladder is a powerful concept for determining the best strategies for this purpose. What does the R-ladder entail, and how can we use it to create a truly closed cycle? Read about our vision and the steps to a circular and sustainable future with plastics.

We cannot live without plastics. However, can we live with them?

Plastics are an integral part of our daily lives. In clothing, packaging, appliances, cars, construction, etc. Plastics are used everywhere because of their versatility. A plastic-free world therefore seems impossible.

At the same time, plastics are a source of carbon emissions, and they introduce microplastics into the ecosystem. Making the plastics economy circular is therefore an important step towards a sustainable future.

The R-ladder: towards fewer plastics, one step at a time

The R-ladder is often mentioned in relation to circularity. This sustainability ladder clearly shows which measures you can take, and in what order, to reduce waste and close cycles. Examples of measures are reduce, reuse, repair, and recycle.

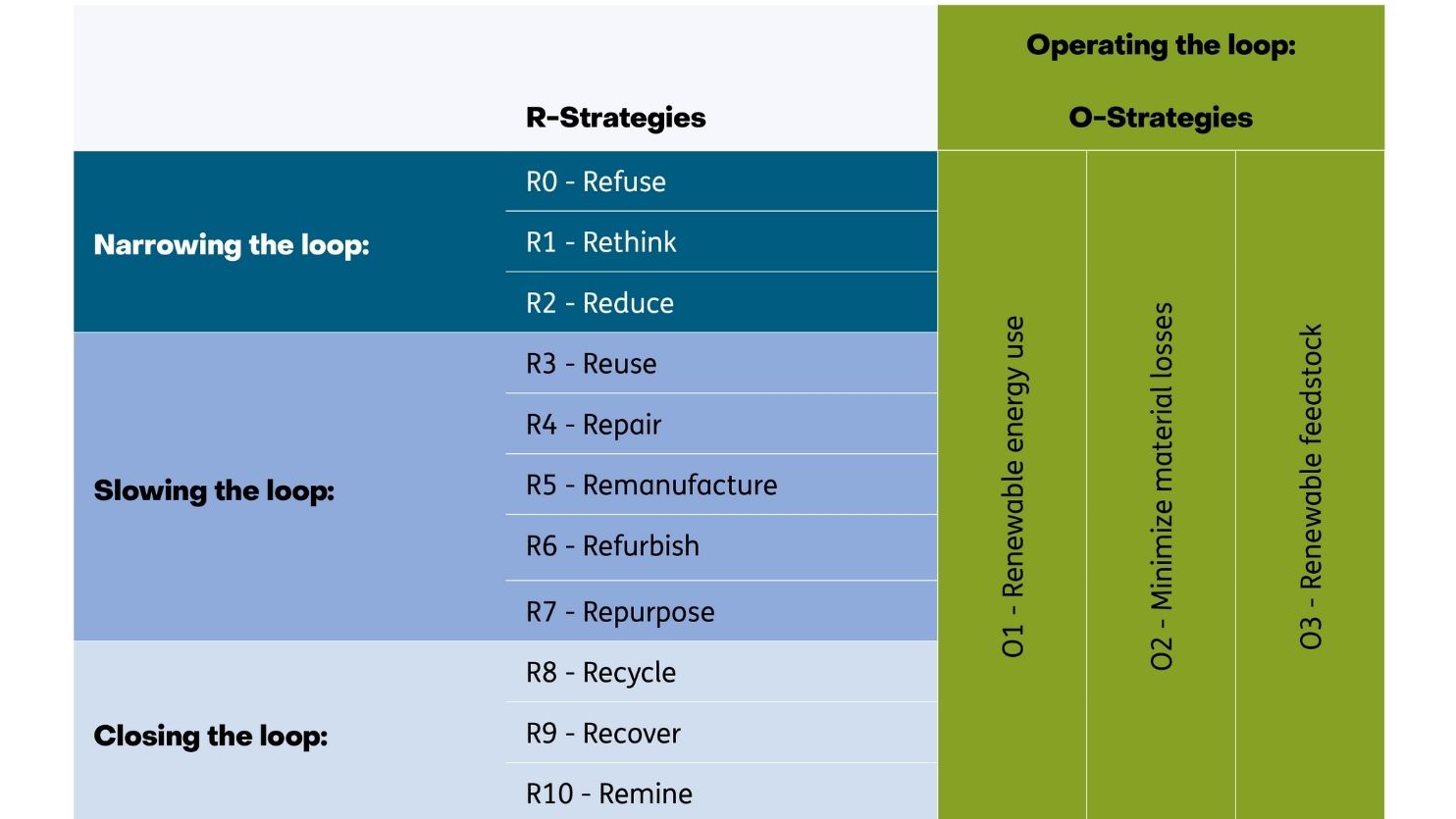

The figure below gives an example of this R-ladder. The various R-strategies can influence the value chain (‘the loop’) of materials and products in 3 ways:

- Narrowing the loop: using fewer materials and products

- Slowing the loop: extending product life

- Closing the loop: recycling and recovering materials from discarded products

An important extra step: 'operating the loop'

The plastics economy is still largely linear rather than circular. To achieve as many environmental gains as possible on the way to a closed loop, we encourage industry to extend the R-ladder with an essential extra step, 'operating the loop'.

Operating the loop involves making circular choices in the design, production, and use phases of products. We call these O-strategies. We distinguish 3 such strategies:

- Procuring sustainable, renewable raw materials for plastics production

- Using renewable energy in all processes

- Reducing materials losses at all stages, from production to use

The figure shows how we add these O-strategies to the R-ladder. You do not have to make a choice in applying the O-strategies, as all 3 should be applied at the same time and as comprehensively as possible.

The higher up the R-ladder, the greater the gain

Back to the R-ladder. If we bring fewer plastics into the world, we will also need to reuse and recycle less. The highest category of the R-ladder – narrowing the loop – therefore enables us to make the greatest environmental gains. This highest category consists of three R-strategies:

- Refuse: refuse unnecessary products and packaging. One example is water fountains instead of plastic bottles.

- Rethink: reconsider why you should use a disposable cup when you can choose a reusable one?

- Reduce: reduce the use of materials, such as vegetables in a plastic bag instead of a plastic tray with a bag around it.

Slowing the loop by extending service life

Once a product has been made, the next category on the ladder is slowing the loop: extending its service life. R-strategies at this level include reuse, repair, remanufacture, refurbish, and repurpose.

- Reuse: reusing products such as clothes and offering refillable bottles

- Repair: repairing broken products and stocking parts

- Remanufacture: disassembling and reassembling products to make them like new

- Refurbish: refurbishing and reconditioning, for example of phones and laptops

- Repurpose: repurposing for other uses, such as making glasses from used wine bottles

Finally: closing the loop

If a product can no longer be made usable, we enter the lowest category: closing the loop by recycling, recovering, and remining. Recycling is seen by many people as sustainable. But although it is important, recycling is lower on the ladder because it uses energy, and losses always occur. The bottom steps of the R-ladder are therefore:

- Recycle: reusing materials, such as making fleeces from PET bottles

- Recover: recovering energy from materials that cannot be recycled – for example, generating energy from waste incineration

- Remine: collecting ocean plastic to make new products

Together, we can close the loop

The R-ladder, combined with the O-strategies, provides a structured approach to using less plastic and making the plastics economy circular. In this process, it is important at all times to consider measures at the highest possible level. These yield the most gains in terms of circularity and sustainability. Both companies and consumers play a crucial role in this transition. Together, we can work towards a more sustainable future where we can use plastics sustainably. So that waste becomes a thing of the past and raw materials are reused again and again.

Would you like to make strides towards a circular plastics economy? TNO makes it possible to identify opportunities and obstacles and work on promising circular solutions.

4 strategic approaches for a circular economy

What does a future-proof, circular, and sustainable plastics economy look like? And what place do plastics have in it? Together with Fraunhofer UMSICHT, we shared 4 strategic approaches for a circular economy in a white paper.

Get inspired

From lab to market: TNO steps up sustainable plastic recycling with dissolution

Webinar: Biobased plastics in a sustainable future

Biobased plasticisers: from compliance to competitive edge

Early results show the potential of circular healthcare plastics

Enhanced solvolysis contributes to the future of composite recycling