De R&D Hub: Research & Development Hub for Plastic Waste Processing

Status project

1 March 2023 - 1 March 2028

In cooperation with

BASF, Covestro, Dow, LyondellBasell, Mitsubishi Chemical Group, SABIC, and Syensqo

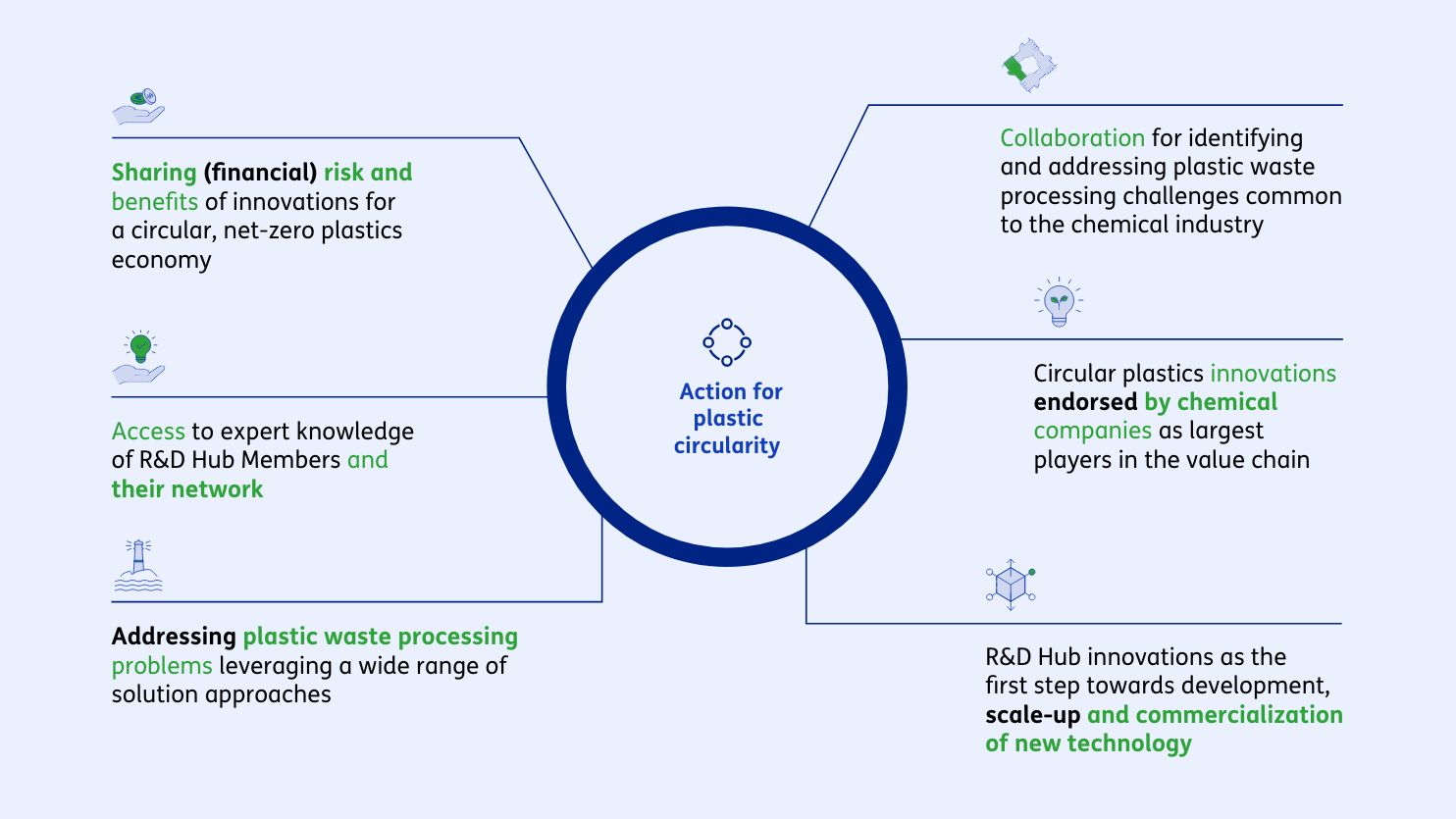

Plastics are vital in our everyday society, but plastic production accounts for about 6% of global oil production. Recycling technologies lag behind the demand for sustainability. The R&D Hub for Plastic Waste Processing, led by TNO, is breaking barriers with innovative solutions. By driving collaboration and advanced recycling, we are paving the way for a circular plastics economy-reducing waste and emissions for a more sustainable future.

Collaborative innovation to tackle waste processing challenges

TNO leads the R&D Hub for Plastic Waste Processing, which was incubated by the Global Impact Coalition (GIC), previously part of the World Economic Forum. The Hub focuses on developing low-carbon waste processing technologies to tackle challenges in plastic recycling.

It brings together 7 industry leaders -BASF, Covestro, Dow, LyondellBasell, Mitsubishi Chemical Group, SABIC, and Syensqo-to collaborate on research projects. This collaboration reduces costs and accelerates results, driving impactful innovations.

The pre-competitive nature of the Hub enables competitors to work together on shared solutions by pooling knowledge and resources. This approach accelerates breakthroughs that benefit the entire industry, from improving recycling efficiency to significantly reducing CO2 emissions.

Key projects driving technological advancements

The R&D Hub focuses on four key projects aimed at overcoming specific hurdles in plastic waste processing and recycling:

- Sensing for sorting: Developing advanced sensor technologies to improve plastic waste sorting and recyclate quality.

- Polymer/inorganics separation at millimeter scale: Improving separation processes at the millimeter scale for mixed waste streams.

- Polymer/inorganics separation at micrometer scale: Addressing even finer separations, crucial for recycling complex materials like composites.

- Enhanced solvolysis for composite recycling: Developing advanced solvolysis techniques to recycle carbon fiber composites more efficiently.

Each of these projects targets critical bottlenecks in the recycling process, offering the potential for reduced operational costs, increased material recovery, and compliance with stricter environmental regulations.

The Global Impact Coalition (GIC)

The Global Impact Coalition (GIC) is a collaborative platform enabling the chemical industry to achieve a circular and net-zero emissions future. Incubated at the World Economic Forum, GIC is an independent coalition guided by global industry leaders. As the industry’s first ever CEO-led coalition, the GIC’s members collaborate to address challenges that cannot be effectively tackled alone.

The GIC provides a cross-industry platform to co-develop and scale-up new technologies and innovative business models to reduce carbon emissions and advance circularity along the value chain.

How does the R&D Hub work?

In annual Ideation workshops TNO together with the 7 Hub members jointly define technology needs and challenges that are subsequently captured in a set of project ideas. The members select the most relevant project ideas which TNO then translates into research projects. These research projects are executed within TNO labs in the Netherlands, with the involvement of European research partners or facilities where needed.

Members actively contribute to shaping the Hub’s research agenda and gain exclusive insights into the resulting technological advancements. This collaborative model ensures that participating companies are equipped with the latest innovations and solutions, positioning them as leaders in sustainable plastics processing. The R&D Hub, open for new members to join twice a year (January and July), fosters broad industry participation, benefiting not just its members but the entire plastics sector.

Impact on the circular economy and plastics recycling

The R&D Hub’s work is expected to have a significant impact on the circular plastics economy. By focusing on the development of sorting and recycling technologies, it will improve the efficiency of plastic waste processing, ultimately leading to more plastics being recycled and reused. The long-term goal is to reduce reliance on virgin materials, lower carbon emissions, and enhance sustainability across the value chain.

Exciting innovations brought along by the ongoing Hub projects include new sensor technologies and advanced separation techniques for complex materials. These innovations could revolutionize plastic recycling by improving purity, reducing contamination, and cutting costs.

Listen to the podcast

Listen to the latest insights on this transformative effort in the "Radio Davos" podcast, hosted by the World Economic Forum, and learn more about how your company can contribute to-and benefit from-these groundbreaking innovations.

Listen to the experts:

- Jan Harm Urbanus, Principal Consultant Circular Carbon, TNO

- Hella Koops, Senior Project Manager Circular Plastics, TNO

- Charlie Tan, CEO, Global Impact Coalition

Ready to collaborate?

The work of the R&D Hub continues, with new projects and innovations being defined through ideation workshops. The next phase will focus on further enhancing these technologies.

As TNO continues to lead these efforts, we are actively seeking new members to join the R&D Hub and benefit from the joint development of groundbreaking plastic waste processing technologies. Don’t miss the opportunity to be at the forefront of innovation in plastic waste processing. Contact us now to join the next wave of technological breakthroughs.

Get inspired

From lab to market: TNO steps up sustainable plastic recycling with dissolution

Webinar: Biobased plastics in a sustainable future

Biobased plasticisers: from compliance to competitive edge

Early results show the potential of circular healthcare plastics

Enhanced solvolysis contributes to the future of composite recycling