The challenge of choosing between sustainable materials for textiles

Imagine preparing for your next football practice and pulling out your favorite team’s jersey, only to realize it’s made entirely from polyamide, a plastic derived from fossil resources. This scenario raises a crucial question for brand owners and textile producers in the fashion industry: Can we create the same jersey using more sustainable, renewable carbon-based materials? The short answer is yes

Identifying the best sustainable & affordable material

Finding the best sustainable material is complex. With numerous options available, from biobased polymers to plastics synthesized from captured CO2, determining the most sustainable and economically feasible choice can be daunting.

This is where TNO’s innovative 3-step framework comes into play, enabling brand owners to find the optimal pathway for sustainable plastic production.

TNO’s 3-Step Framework

Step 1: Search the options

The first step involves a search of options through an analysis of the value chains and technologies required to produce similar materials based on renewable carbon.

For instance, the fossil-based polyamide (PA) in your jersey can be replaced by a biobased or CO2-based version of the same polymer with identical properties. It could also be replaced by an alternative biobased polymer that provides the desired properties.

We define three pathways:

- (Novel) Biobased alternative polymers,

- Drop-in biobased polymers,

- CO2-based polymers.

In this case, the production pathways were specified for bio-PA6 (from forest residues via pyrolysis eventually to caprolactam polymerization into bio-PA6), and synthetic PA6 (from captured CO2 via methanol to BTX, cyclohexanon, eventually to caprolactam polymerization into CO2-based PA6).

To find the suitable novel biobased alternative polymer, we are leveraging TNO’s extensive knowledge of (biobased) polymers by identifying novel biobased alternatives that offer at least comparable properties. In this case, the search identified a novel copolymer (PPF) of 1,3-propanediol made from Used Cooking Oil and FDCA made from plant-based sugars, that could replace PA in jerseys. This step ensures a clear understanding of the production processes that substantiate the three pathways.

Want to know more?

Download our latest whitepaper to explore the pathways to sustainable plastics and join us for our webinar on 11 March 2025 for exclusive insights and expert discussions.

Step 2: Compare on sustainability and feasibility

To be able to choose the 'best’ material pathway for the jersey, the sustainability impact and economic feasibility of the different pathways was assessed in order to compare the options.

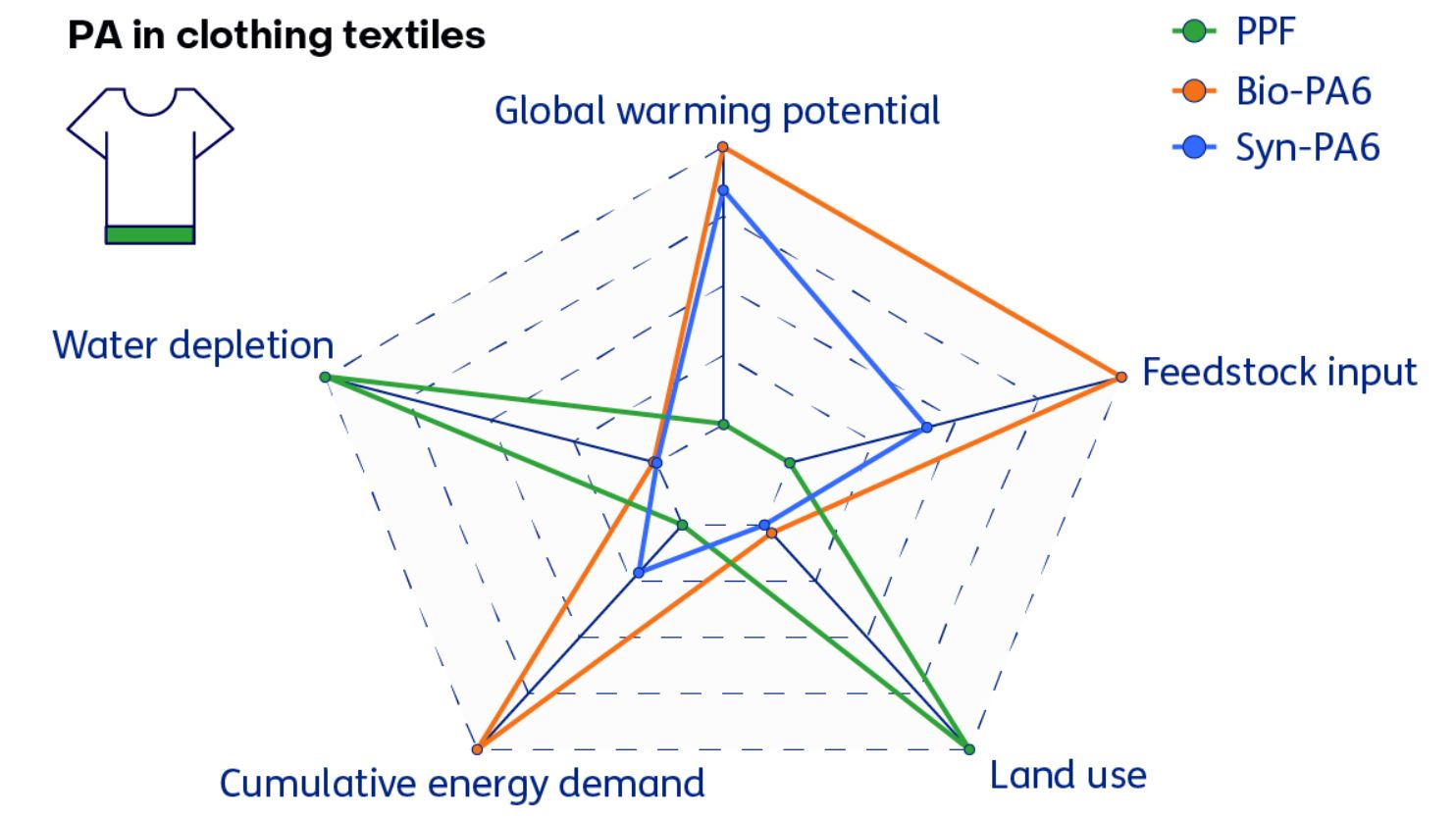

Sustainability impact was analyzed in terms of global warming potential, cumulative energy demand, water depletion, land use, and feedstock input required though an analysis model combining Material Flow Analysis (MFA) and Life Cycle assessment (LCA). Generally, a Life Cycle Analysis is the most reliable method to determine sustainability of a process. TNO’s sustainability assessment model allows for system optimization across impact factors and constraints.

The sustainability assessment results show that, overall, the novel copolymer PPF has the lowest sustainability impact. It scores best in terms of global warming potential (kg CO2eq/ton, cradle to gate), cumulative energy demand (MJ eq) and feedstock required (in tons). On the other hand, CO2-based PA6 scores best in terms of and land use, whilst Bio-PA6 scores best on water depletion.

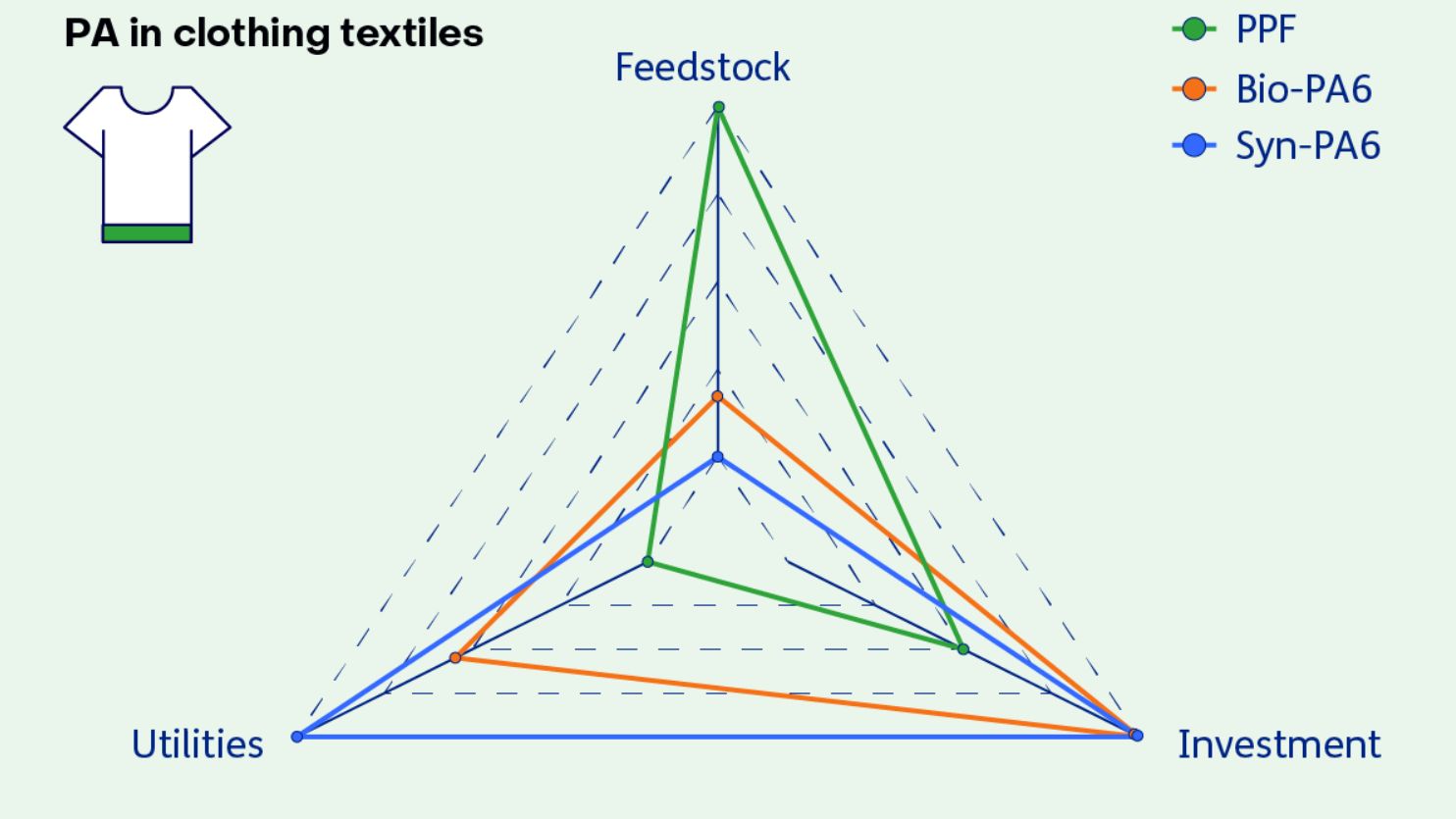

Subsequently, economic feasibility was estimated for the pathways by considering costs for feedstock, utilities (including energy, heat/steam, and hydrogen), and investment required. The results suggest that PPF scores best on economic feasibility, followed by bio-PA6, and lastly CO2-based PA6. Even though the cost of the (biomass) feedstock for PPF production Is significant, the lower costs in both utilities and capex make it the best option from a feasibility perspective.

Step 3: Decide on the best option for the jersey

TNO’s framework allows for optimization of the results based on the specifics of the situation. For example, in the case of the jersey we might consider the availability of biomass feedstock (forest residues or used cooking oil) for the options and/or examine what materials are already available or obtainable from existing or new suppliers.

Given its additional potential for improved property performance, economic feasibility, and sustainability benefits, the brand owner can further explore the use of the novel biobased polymer PPF in their football jersey's.

TNO provides a systemic, data-driven approach

In conclusion, TNO’s 3-step framework provides a clear, data-driven approach for brand owners to select the best renewable carbon-based alternatives to their fossil plastic materials. By evaluating value chains, material properties, economic feasibility, and sustainability impacts, this framework helps brands make informed decisions that align with both environmental goals and economic realities. The result is a more sustainable future for the fashion industry and beyond.

Discover how you can use sustainable, renewable carbon-based materials for your products. Need a tailored advice?

Get inspired

Collaboration for sustainability: better results through joint innovation

Webinar: Biobased plastics in a sustainable future

Biobased plastics

23 questions about biobased plastics in a sustainable society

Working on biodegradable plastic