Prospective Life Cycle Assessments for future-proof product design

To prevent novel materials and products from doing harm to humans and ecosystems, the European Commission (EC) is aiming to steer industry towards safer and more sustainable products on the EU market. As an industry, how do you choose from the many different frameworks and methods to fulfil this? And how can you anticipate future regulations now? TNO bridges policy, science and industry, by developing insightful prospective Life Cycle Assessments (LCA’s) to guide safe and sustainable product design.

‘The products you make should have minimal negative impacts on the environment, society and economy.'

How to anticipate safe & sustainable product design

Carlos Felipe Blanco is a senior scientist at TNO, specialised in Circularity & Sustainability Impact. When he describes safe & sustainable product design, he emphasizes the triple bottom line:

‘The products you make should have minimal negative impacts on the environment, society and economy. The EC is pushing this concept, so guidelines and regulations for product development are coming. We want to help industries to anticipate those regulations in the early stages of product development. To reduce costs, minimize risks and identify opportunities.’

What is a prospective LCA?

‘A Life Cycle Assessment is a way to size the environmental implications of human economic activities. A standard LCA measures the impact of every step in the lifecycle of an existing product. Not only going back to the raw materials and manufacturing, but also during the use and the end of the product’s life. A prospective LCA is meant for future products. What could be the future impact of a product that is still at an early stage of development?’

How TNO develops more insightful prospective LCA’s

At TNO, we support producers, innovators, researchers, and governments in developing a Decision Support approach that enables the industry to effectively weigh risks and benefits in the early stages of their design process.

Additionally, TNO informs prospective LCA methods with deep sector-specific knowledge from in-house expertise groups, like circular plastics and energy technologies. TNO has a profound understanding of innovation.

Felipe: ‘At TNO we are innovators ourselves. We know about the many uncertainties related to the product’s evolving design and the dynamic external context where the product will be released in the future. Also, we can manage those uncertainties and assumptions in a responsible way, because we are neutral by definition.’

Reducing costs and other benefits

Conducting an insightful prospective LCA at early stages of product development offers many benefits. Felipe sums them up:

- ‘First of all it reduces costs: making changes while you’re still designing is much cheaper than when you’re already producing.

- Another benefit is that developers can derisk the product, by anticipating design choices that could go wrong.

- The third benefit is that it helps prioritize research. Usually the focus is on quality and cost. But when you also focus on safety and sustainability you’ll have a more complete roadmap for addressing the things that matter during the remaining steps of innovation.’

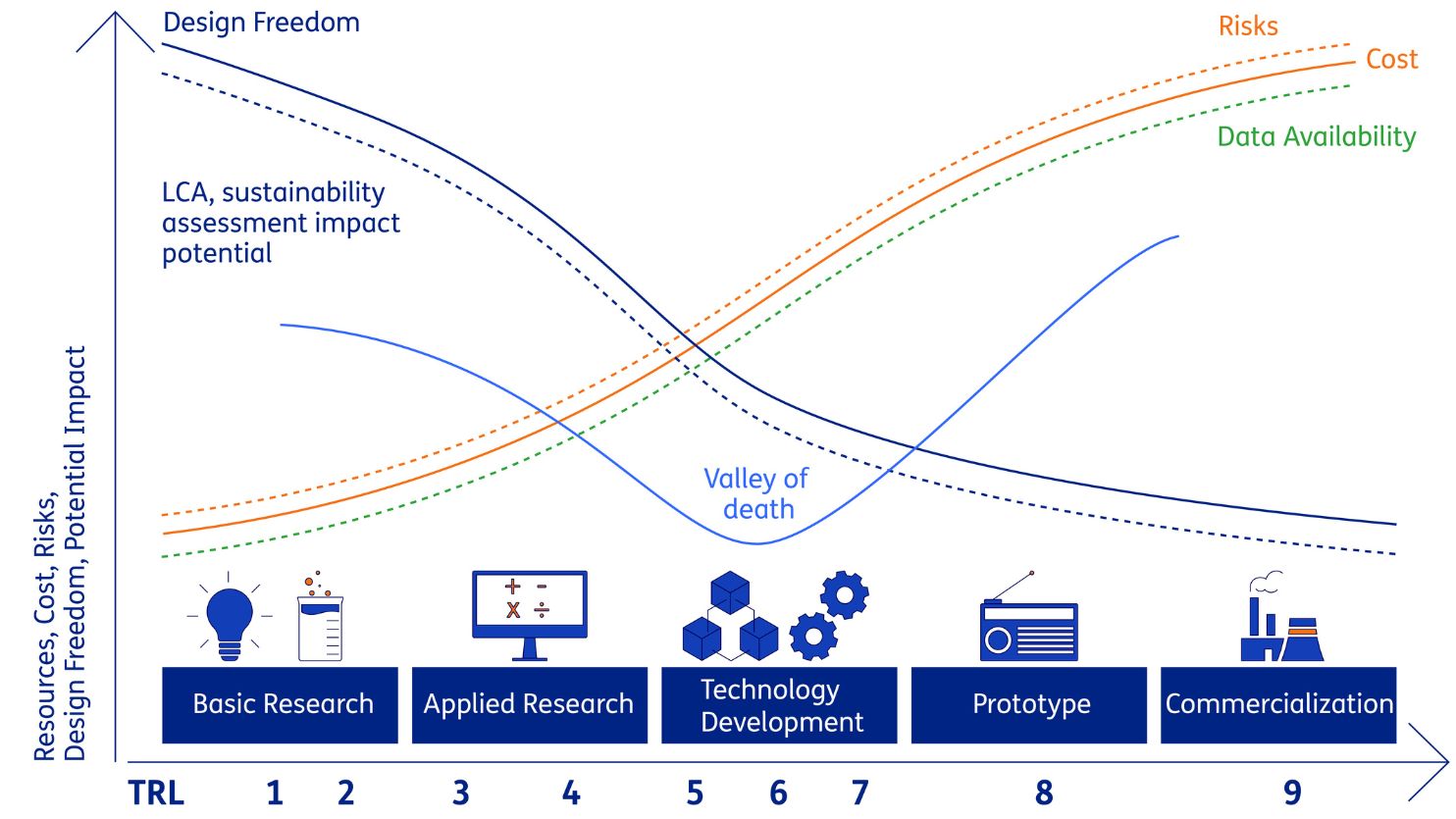

In this way, an LCA can also help bridge the so-called “valley of death”, where products are too advanced to receive basic research funding but still too risky or underdeveloped for substantial private investment. An insightful prospective LCA can avoid product developers from getting locked in a type of design that won’t be able to overcome the risks.

Moreover: increase opportunities

As a designer or manufacturer you could settle for standard LCA’s or online tools that advertise quick, simple and cheap LCA calculations. But you will miss opportunities. At TNO we tap into the design freedom in early stages of product development. For example: at the design table, you can easily change your mind about materials. With our systematic approach you can explore all possibilities and identify opportunities for more competitive and sustainable products at the end of the R&D pipeline.

We recently applied this approach with a partner developing an innovative type of solar panel. They were evaluating numerous design alternatives, all with different levels of technological complexity and cost, yet we were able to identify a simple material change that would substantially improve the environmental profile of the panel. It was an easy change that far outweighed any benefits obtained from other more difficult changes. And this remained true while taking into account more than 15 types of environmental indicators and considering future developments in recycling, renewable electricity and other relevant sectors.

How does a prospective LCA work?

Felipe first explains a standard LCA: ‘With an existing product we analyse the activities that comprise the whole value chain: raw material extraction, equipment manufacturing, usage, disposal, etc. Each activity has an impact, like emissions or the use of water. These impact data add up to an LCA score.

An insightful prospective LCA will not give you a single score. Rather, due to design choices that are still to be made and uncertainty about future legislation and context we make assumptions,

we draw and evaluate scenarios, and we make recommendations. Furthermore, we’ll take competitors into account: how will their competing product’s performance evolve in the future.’

'We have effective ways to fill these gaps and extrapolate (assumed) data to an industrial scale.’

Challenges and collaborations

With prospective LCA, the lack of real data can be a challenge. But to Felipe that isn’t a big concern: ‘Of course there is a data-gap when working with future products and contexts. But we have effective ways to fill these gaps and extrapolate (assumed) data to an industrial scale.’

To further develop the field, TNO is collaborating actively with various industry partners, government institutions, universities and research centers.

Enhance your innovation power

Are you developing new products and services and do you fundamentally want to transform the way you innovate? Work with us at TNO. We do more than just provide you with indicator LCA scores. We guide you on how to interpret and use the results of the LCA to take practical decisions to improve your product designs and R&D pipelines.

Let’s innovate together.

Get inspired

Urban mining crucial: more critical and strategic materials from electronics and electrical devices

Netherlands Materials Observatory (NMO) officially opened

Recovering critical raw materials from LFP Batteries

Critical raw materials

Circularity of large household appliances in Kenya