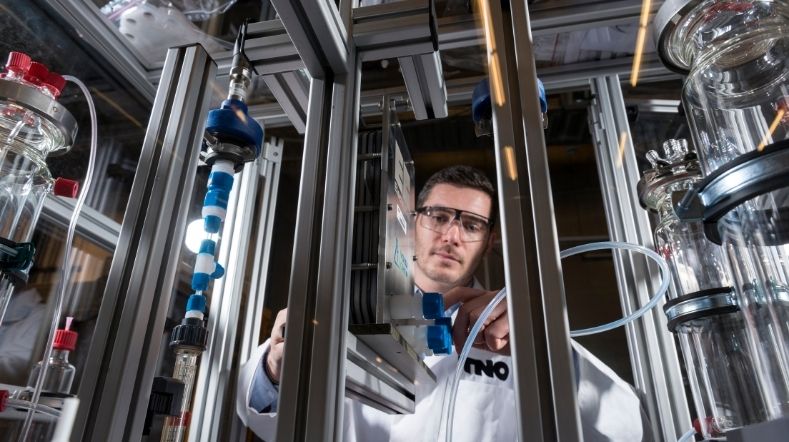

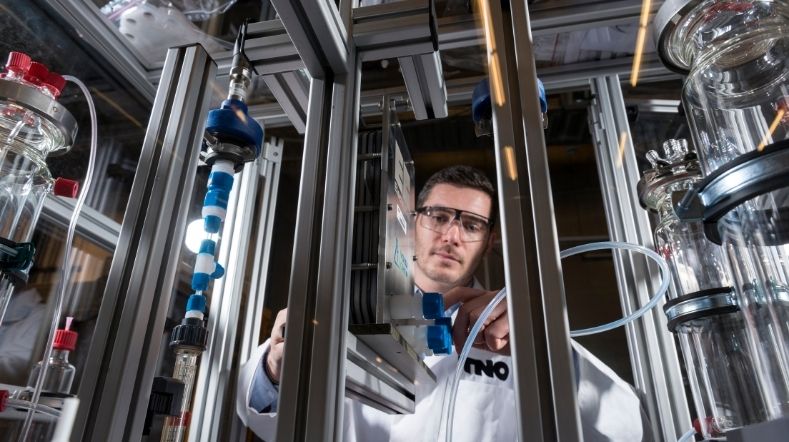

Carbyon: the TNO spin-off innovating in CO2 filtration technology

One day as Hans De Neve was working at TNO, he had a brilliant idea for an innovative CO2 filter. With TNO’s support, he founded the cleantech start-up Carbyon, which has since grown into a thriving company. With 50 dedicated employees, Carbyon is already building its first machine. ‘Our mission is to capture billions of tonnes of CO2 from the air.’

Climate change is a major focal area for TNO, which is working on all kinds of innovations, from the latest solar and wind energy technologies to satellites that monitor greenhouse gases and a global emissions atlas. What’s more, TNO itself is starting up promising companies that use its own technology to come up with innovative solutions. One of those start-ups is Carbyon, which aims to make CO2 filtration from the air scalable and affordable.

Traditional filters are far too slow

Carbyon was founded by physicist Hans De Neve, who worked at TNO on solar panels for the European market. In his spare time, he immersed himself in the subject of CO2 capture. ‘I knew it was possible to extract CO2 from the air using filters,’ says De Neve. ‘These filters consist of a carrier with a special layer. They are placed in a machine that blows air through the filters. The CO2 then sticks to the layer, penetrates it, and is retained in the filter. The captured CO2 can be used to make green fuel or stored safely underground.’ While the technology is promising, the project also had its challenges. For every 1 million air particles, there are only 420 CO2 particles. This means a huge amount of air has to pass through the filter for it to have any meaningful effect. With existing filters, this process was far too slow.

Innovation on the back of a failed experiment

When De Neve worked with solar panels at TNO, he dealt with technologies such as atomic layer deposition, which allows material one atom thick to be applied to a carrier. ‘My thinking was: if we applied a layer that the CO2 sticks to just as thinly, the CO2 could penetrate the filter much faster. However, that still left the problem of the carrier. To really filter faster, the carrier needed to have a large surface area, so that it would come into contact with a lot of air. For that, you need a very light material, otherwise the filter will be too heavy.’

One day at work, he experimented with amorphous silicon. Although the experiment didn’t work out, it did produce a highly porous material. ‘Because it was so porous, it was also very light. Suddenly, it occurred to me that this might be good carrier material! And that’s how Carbyon came into being.’

‘I knew it was possible to extract CO2 from the air using filters. These filters consist of a carrier with a special layer. They are placed in a machine that blows air through the filters.'

Experimenting elsewhere while on the payroll

That same year, in 2018, TNO organised a challenge within the company. De Neve: ‘You could submit the wildest ideas you ever dreamt of. Some colleagues and I entered with the idea of developing a filter that captures CO2 much more efficiently than existing filters.’ They were one of the three lucky winners, receiving a prize of €50,000 .

De Neve and his colleagues used the money to carry out some experiments, which produced some interesting findings. Under the Tech Transfer programme and in cooperation with HTXL, the high-tech incubator organisation from Eindhoven , TNO helped De Neve launch a start-up. Thus Carbyon was born, with TNO as a co-shareholder. ‘TNO offered to continue paying my salary in the initial phase while I got my company off the ground,’ De Neve says. ‘This gave me the space I needed to really get going.’

TNO Tech Transfer

TNO starts new companies, would you like to know how? Check out the link below.

Filtering 200 times faster

De Neve and his colleagues spent more than 3 years refining the filter. ‘We now have a filter that works 200 times faster on CO2 than traditional ones,’ De Neve enthuses. ‘It’s cheap to make, so the technology is scalable. What seemed impossible just a few years ago is now right there in front of us.’

The next step for Carbyon is to work more on developing the machines to hold the filters. ‘Next year, we’ll build the first outdoor machine, which will be installed on the High Tech Campus in Eindhoven. That will be the first concrete proof that our innovation works.’

‘We’re the only country in the world with this equipment. If we gain an international foothold and start exporting machinery, it will create new high-productivity jobs and strengthen our position as a country of innovation.

Value for the environment and the economy

Filtering CO2 from the air is crucial, De Neve asserts. ‘If we don’t act now, the planet will become unliveable. We also need to reduce our current emission levels, of course: we’ve been emitting far too much for the past 150 years. With Carbyon, we’re giving future generations a tool they can use to right our wrongs.’

Carbyon’s innovation is not only useful in the fight against climate change. It also offers great opportunities for Dutch earning power, as De Neve explains. ‘We’re the only country in the world with this equipment. If we gain an international foothold and start exporting machinery, it will create new high-productivity jobs and strengthen our position as a country of innovation. Moreover, our innovation can help make our chemical and steel industries more sustainable – two sectors that are a major part of the Dutch economy, but badly need to reduce CO2 emissions.’

Machines around the world

Carbyon has now grown into a company of 50 employees. What does De Neve think the next 10 years have in store? ‘We want to set up production lines quickly and supply our machines to the entire world. We’re in talks with a number of machine builders to see if they can help us scale up the filters and machines. TNO remains a key partner for us at this stage. I see no insurmountable problems: the materials we need are cheap, safe, and widely available. The main thing we need to do now is secure more funding and start building.’

‘Our ultimate mission is to remove billions of tonnes of CO2 from the air to keep our planet liveable. This will take some time, but I’m confident we can do it.’

Climate change

Want to know more about TNO's impact on climate change?

Get inspired

Scaling-up electrochemical technologies for renewable ethylene production

CO2 infrastructure and transport

Transition co2 neutral mobility 2050

TNO’s next generation biorefinery accelerates material transition

Port of Rotterdam as a key European hub for sustainable carbon