Clean and robust hydrogen engine pivotal for achieving emissions targets heavy transport

The hydrogen engine is a technology, which uses hydrogen directly as a fuel in an internal combustion engine. It’s an extremely clean, robust and cost-effective alternative to fossil fuel engines. TNO is working with industry partners on innovative hydrogen concepts like High Pressure Direct Injection (HPDI) that meet European zero emission standards. Xander Seykens and Jack Bloem, experts in innovative combustion concepts, explain how it works.

Hydrogen engine for climate goals in heavy transport

‘It is quite remarkable how little attention the hydrogen engine receives, both among transport entrepreneurs and in sectors such as construction,’ says Xander Seykens, Senior Research Scientist at TNO and an expert in innovative combustion concepts.

Seykens explains: ‘To meet the 2030 emission targets, the priority order for alternatives can be structured as follows: electric first, then hydrogen, followed by e-fuels. Battery-electric vehicles are highly efficient with minimal energy losses, so they should be deployed wherever possible. Electric trucks are already available, and development is ongoing. However, given the projected demand and the number of trucks that would need to be electrified to meet emission targets, there simply will not be enough charging capacity—not even by 2030-2035. This is why a second alternative is essential, and given the targets set, hydrogen is the logical choice, particularly for heavy-duty transport, industrial applications, and long-distance or extended operations. If hydrogen is not viable in certain cases, e-fuels can be used, but their availability and short-term scalability remain limited.’

Hydrogen (combustion) engine

So hydrogen will play a pivotal role in making logistics CO₂-neutral. In the construction sector, it can significantly reduce both CO₂ and NOx emissions to extremely low levels. This can be achieved either through hydrogen fuel cells, which truck manufacturers and shipbuilders are actively developing, or through hydrogen engines, where hydrogen is used directly as fuel in a traditional combustion engine. However, the latter solution remains largely overlooked by transport entrepreneurs, contractors, and governments.

Jack Bloem, Business Developer at TNO, offers an explanation: ‘Due in part to 'Dieselgate', the combustion engine has been cast in a highly negative light. Additionally, the word ‘combustion’ often evokes associations with polluting emissions. Yet, the beauty of hydrogen engine technology is that it is remarkably clean. Just like battery-electric solutions, the hydrogen engine is classified as zero-emission under European emissions legislation.’

Sign up for our webinar

Join our Meet the expert session to discover our latest research and development on hydrogen engines, our vision on the future and necessary next steps for upscaling. Together towards sustainable HD transport.

How does a hydrogen engine work?

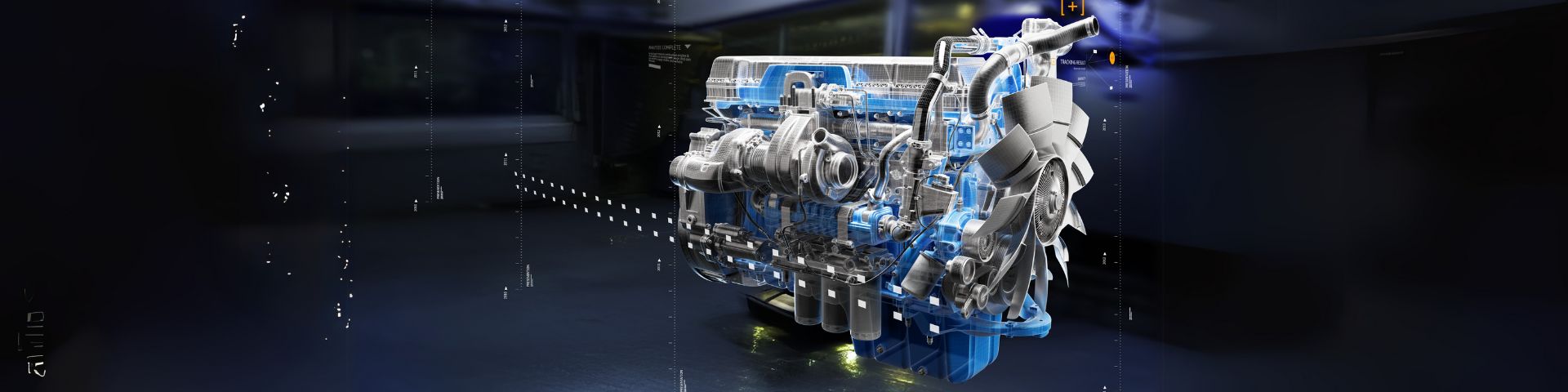

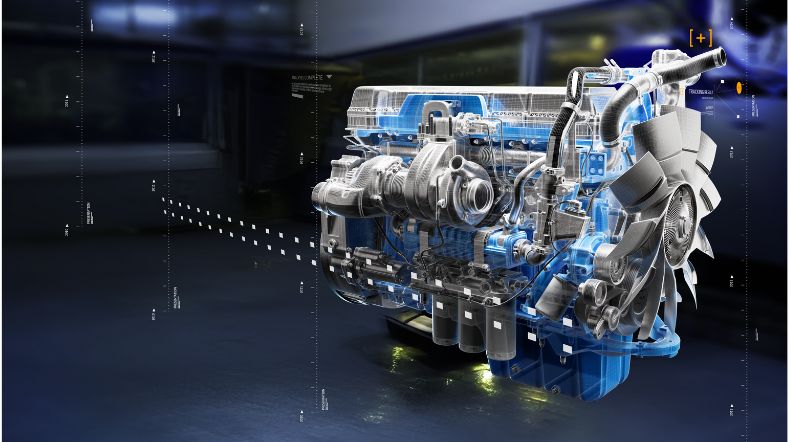

Fundamentally, a hydrogen engine operates similarly to a petrol or diesel engine, with both concepts being adaptable for hydrogen application.

Xander Seykens explains: ‘In the petrol-based concept, where a fuel mixture is ignited by a spark plug, the goal is to maximise power and efficiency while maintaining stable combustion. This allows for exceptionally clean emissions. In our test cell, we have already created conditions where the exhaust gases were cleaner, with lower NOx levels, than the outside air entering the engine.’

The hydrogen-powered petrol engine is particularly robust due to its low complexity, especially when no exhaust aftertreatment is required. This makes it highly suitable for marine applications, such as ships, as well as stationary power generation for construction sites, festival grounds, and shore power systems.

Additionally, this concept offers an easier conversion solution for making existing engines more sustainable. Seykens notes: ‘Inland and coastal vessels typically last around 30 to 40 years. With this approach, the powertrain can be upgraded mid-way through its technical lifespan, avoiding the need for costly replacement.’

‘Hydrogen can also be applied in the diesel engine concept, offering even higher efficiency and performance than conventional diesel engines. This makes it an interesting and sustainable alternative for heavy freight transport, without significant technical modifications to the truck powertrain.’

TNO unique research partner in High Pressure Direct Injection (HPDI)

Hydrogen can also be applied in the diesel engine concept, offering even higher efficiency and performance than conventional diesel engines.

‘This provides a highly promising and sustainable alternative for heavy freight transport, without requiring major technical modifications to the truck powertrain,’ explains Xander Seykens.

Since high power density is particularly crucial for trucks, TNO is developing High-Pressure Direct Injection (HPDI). ‘TNO made timely investments in facilities to advance this new technology, making us one of the few research institutions worldwide with this expertise,’ Seykens adds.

HPDI operates similarly to a diesel engine, with fuel self-igniting through compression. Seykens: ‘However, since hydrogen is more difficult to self-ignite, a very small amount of diesel — about 2% of the total fuel volume — is injected just before the hydrogen. This initiates ignition due to the heated environment, allowing the hydrogen to combust efficiently. At TNO, we are also working towards eliminating the need for that small amount of diesel entirely.’

Advantages hydrogen engine

The hydrogen engine offers several significant advantages over fuel cells, as Xander Seykens explains: ‘It is a robust technology. Fuel cells degrade over time and are highly sensitive to hydrogen quality. This becomes a challenge as we scale up hydrogen distribution with backbone networks — contamination will occur, requiring filtration at the refueling station. As a result, long-term reliability is not guaranteed. The hydrogen engine, on the other hand, does not suffer from this issue; it is largely a proven technology. This makes downtime — an important and costly factor in logistics — a much smaller risk.’

Additionally, the hydrogen engine has a clear cost advantage over fuel cells. Seykens also highlights the geopolitical benefits: ‘A hydrogen engine can be produced entirely within the EU, whereas fuel cells and their batteries rely on raw materials sourced from outside Europe. Investing in hydrogen engine technology strengthens our economy by reducing dependence on foreign supply chains, making Europe more energy-secure.’

40 years of experience in combustion engines research

TNO has an outstanding track record for accelerating hydrogen engine development. For over 40 years, TNO has been at the forefront of innovation and research, making combustion engines cleaner and more efficient.

Jack Bloem explains: ‘For the past five years, we have specialised in sustainable fuels and developed test facilities with our own hydrogen infrastructure. This enables us to connect trucks with trailers and use hydrogen across all our test cells.’

Powertrain Performance Assessment Center

In our Innovation Center for Sustainable Powertrains (ICSP), we test new fuels on engines and fuel cells. There is even a unique Altitude Climate Chamber, where we test vehicles under extreme conditions, such as very low and high temperatures and driving at 4000 meters altitude.

Through numerous projects and innovation programmes, TNO has translated hydrogen engine technology from theory into practice. Xander Seykens adds: ‘In the Green Transport Delta - Hydrogen (GTD-H) programme, we developed the first prototypes in collaboration with industry, including a truck, a barge, and a genset. These prototypes successfully demonstrated that hydrogen engines are viable for such applications. Moreover, GTD-H has further strengthened our already solid position in engine technology.Within the emerging sector of sustainable powertrains, hydrogen engines can play a key role in boosting the Dutch earning capacity. Moving forward, the focus should extend beyond engines to include advancements in hydrogen storage.’

Challenges of hydrogen

Just like petrol and diesel engines, hydrogen engines have significant potential for further efficiency improvements. However, hydrogen also presents unique challenges, as Xander Seykens explains: ‘Hydrogen combustion is more difficult to stabilise in the petrol engine concept. Additionally, hydrogen's low energy density makes storage a challenge. On the other hand, hydrogen has the potential to achieve greater efficiency than diesel due to its rapid combustion process.To fully harness this potential, we are exploring the necessary hardware and control systems. We are only at the beginning of a long development journey, with enormous possibilities ahead.’

‘For the past five years, we have specialised in sustainable fuels and have test facilities with our own hydrogen infrastructure. This allows us to connect trucks with trailers and use hydrogen in all our test cells.’

Shorten time to market

OEMs are increasingly turning to TNO to expand their expertise in hydrogen engine technology. Xander Seykens explains: ‘Some manufacturers lack hydrogen infrastructure entirely, while others are specifically interested in our HPDI innovations. Partners approach us with a range of technical questions, such as: ‘What compression ratio should be used?’, ‘Which injection technology is best?’, ‘How can a homogeneous mixture be achieved?’, ‘How much can HPDI improve engine efficiency?’, and ‘Which concept would work best for my application?’’

Jack Bloem adds: ‘Partners choose TNO because of our strong reputation in hydrogen engine technology. In recent years, we have made significant investments in this field and regularly present our findings at leading conferences. Moreover, we bridge the gap between theory and practice by validating our knowledge in real-world applications — an invaluable asset for our partners. As a result, we help them significantly reduce their time to market.’

Large-scale adoption from 2030

Both OEMs and potential customers appear to be waiting for further developments in hydrogen infrastructure. However, this is expected to change once European and Dutch plans for a robust hydrogen network are implemented.

Xander Seykens explains: ‘The Alternative Fuels Infrastructure Regulation (AFIR) mandates the establishment of hydrogen refueling stations along all major roads in Europe. In the Netherlands, this is being further developed through the SWIM regulation. It’s a promising start, and the strong interest from industry is encouraging. Unlike electric trucks, hydrogen requires a less dense refueling network, which makes large-scale implementation more feasible in a shorter timeframe.’

Jack Bloem is also optimistic: ‘Dutch Gasunie is developing a national hydrogen backbone, expected to be operational by 2031. The SWIM regulation aims to establish a nationwide network of 30 hydrogen filling stations by 2030. However, for hydrogen to compete with diesel, the price must drop from the current €20 per kilo to around €6 per kilo — the tipping point for cost competitiveness. Blue hydrogen production can play a key role in scaling up the hydrogen economy while simultaneously advancing green hydrogen production. Logistics could serve as a catalyst for hydrogen adoption, eventually expanding into other sectors. By that time, I expect higher production volumes for hydrogen trucks, with the hydrogen engine emerging as a viable zero-emission alternative, complementing electrification.’

Get inspired

Health of electric bus batteries now measurable on-site via charger

Transition co2 neutral mobility 2050

TNO accelerates electrification of logistics and construction through a deeper understanding of batteries

The hydrogen engine ignites the future and earning power of Europe

TNO helps battery and vehicle sector with future-proof implementation of battery passport