Martin Voorma and TNO tackle vibrations

‘Devise an innovative solution to ground vibrations caused by passing trains': this was the challenge thrown down by ProRail two years ago. Such vibrations may cause damage to buildings and nuisance to local residents. Martin Voorma of the company MIS7 was picked as the winner. His unique solution, respectful of nature and the environment, was a master stroke. The result was that his idea needed to be worked out in every detail. Martin knew that the calculations and output were not possible for him as a small company without help. Previous experience of collaboration with TNO meant he was quick to engage the organisation. We are now two years on and Martin, together with TNO Fast Track, is several phases further.

Martin Voorma is a biologist and for 10 years, he has been developing pipes that are biodegradable in the ground. This formed the basis of his innovation for ProRail: 'Worldwide, thousands of kilometres of plastic pipes are placed in the ground. These pipes eventually degrade and microplastics enter our environment and drinking water. I think that will be the new situation as regards PFAS in 10 or 20 years. And the pipes I develop are made from biopolymers with a degradation trigger. The addition of another substance causes the pipe to degrade completely. When ProRail's challenge came my way, I was reminded of a scientific paper on phononic crystal, which would absorb those vibrations. The combination of the crystal and the fact that it is 100% biodegradable ensured the win.'

'The real calculation work and in-depth scientific research to see exactly how it works – I couldn't do that alone. I engaged TNO and fortunately everything was handled very well by Aart Willem Benschop and his team," Martin explains. "Usually, scientists are very reserved in their statements. The team was enthusiastic right after the initial calculations. And if it makes a scientist happy, that means it’s quite promising.'

'The combination of the crystal and the fact that it is 100% biodegradable ensured the win.'

Together with TNO, Martin was able to go through the feasibility study phase and the second phase of the field trial followed. 'I provided the piece of land and TNO provided the computer simulation model that calculates at what depth and width the pipes made of the phonic crystal needed to be put into the ground. We laid out the pipe system and simulated the vibrations in various phases using a drop weight. Measuring the vibrations was outsourced to Movares and TNO processed the data in a simulation model. Weather conditions and broken sensors caused many delays, but finally the last measurements were taken in December 2024. It’s always exciting to wait for the outcome. Fortunately, in early 2025, the results appeared positive, so we can fine-tune further to absorb the vibration from a train.'

Martin is proud of the collaboration with TNO Fast Track and the results they have achieved. 'When I say that I’m working with TNO, it opens a lot of doors. It’s so incredibly important to work together on innovation in order to make any progress at all.'

'When I say that I’m working with TNO, it opens a lot of doors. It’s so incredibly important to work together on innovation in order to make any progress at all'

TNO Annual Report 2024

Read the story of MIS7, along with many other inspiring customer stories, in the TNO Annual Report 2024

Get inspired

Industrial and conceptual construction

Time setter story: Nienke Dijkstra

Building materials

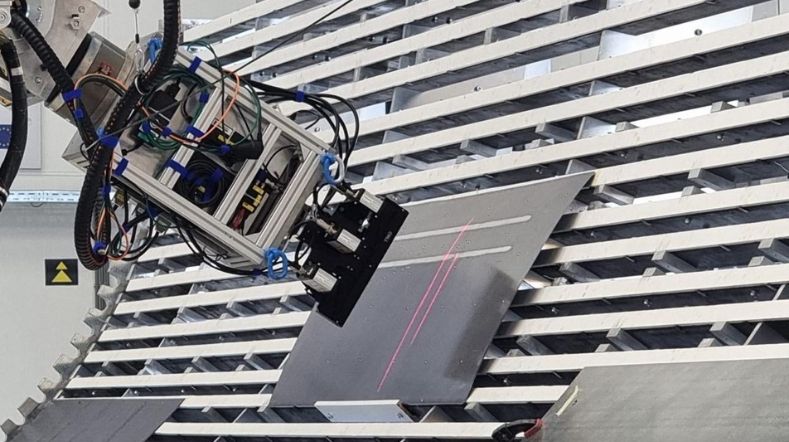

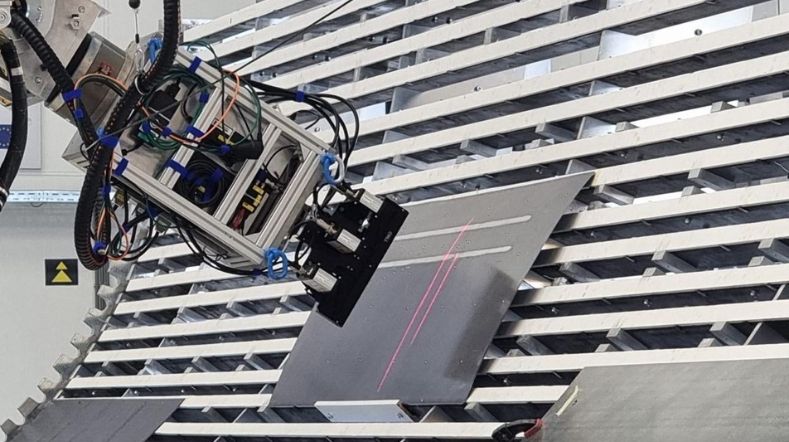

Non-destructive inspection

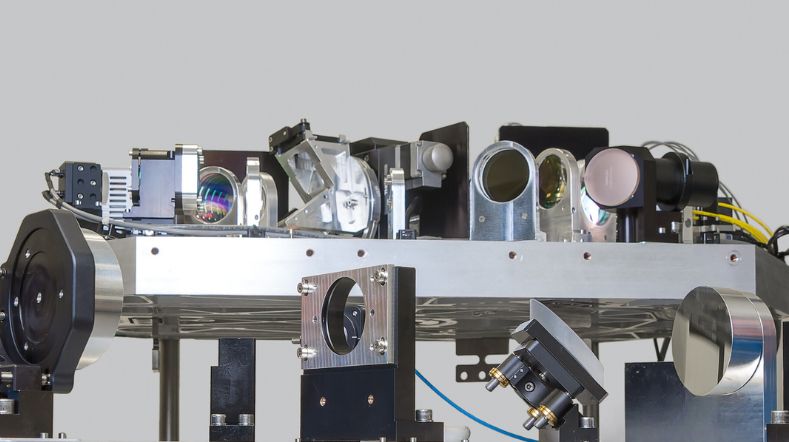

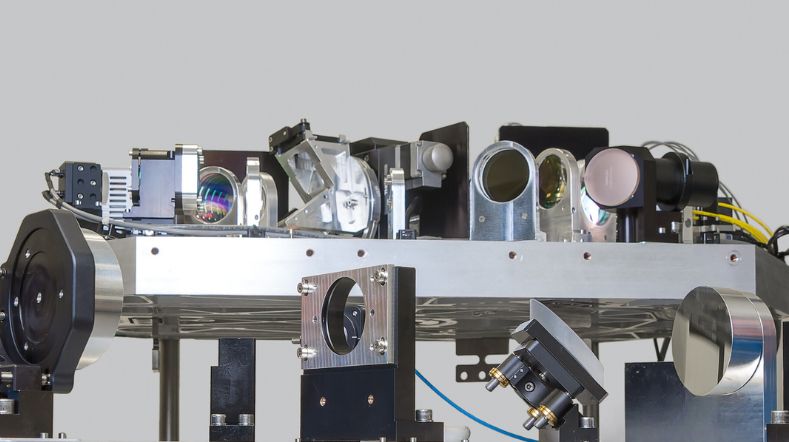

Optics