TNO accelerates electrification of logistics and construction through a deeper understanding of batteries

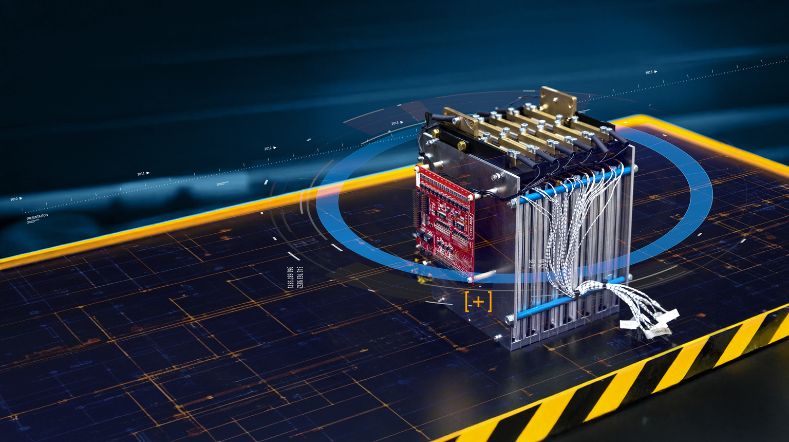

Battery-electric vehicles are already playing a crucial role in advancing fossil-free mobility. However, significant improvements can still be made, particularly in terms of longevity, safety, and sustainability. TNO develops Battery Management Systems (BMS) to enhance the understanding of batteries and optimise their performance. This way, smaller OEMs of specialised vehicles can benefit from batteries that are better suited to their specific applications, ensuring higher efficiency and reliability.

Increasing number of battery-electric vehicles

Battery-Electric Vehicles (BEVs) are currently the primary solution for decarbonising transport. With a wide range of models already available, the technology has reached a high level of maturity. Even heavy-duty electric transport, once considered unfeasible, is now a reality. As battery prices continue to fall and performance improves, electrification is set to expand even further.

Feye Hoekstra, Battery Scientist at TNO, explains: ‘Battery technology has accelerated rapidly. Five years ago, the idea of battery-electric trucks seemed unrealistic, yet today they are widely used. Batteries are achieving higher energy densities and greater power, making even battery-powered planes a possibility. However, with batteries capable of storing such high energy levels, new challenges arise — particularly in terms of lifespan and safety, which become even more critical. At the same time, affordability remains key. So how do we ensure costs remain under control while continuing to improve performance?’

‘We want to understand what happens inside batteries to achieve more energy and a longer lifespan. Building a functional battery pack is not difficult, but maximizing performance, lifespan, and safety is a challenge.’

Understanding batteries better

At TNO, multiple departments are working on the battery technology of the future, covering a wide range of research areas — from developing new materials to improving recycling techniques and second-use applications. At TNO Powertrains in Helmond, the primary focus is on optimising battery usage to enhance efficiency and longevity.

Feye Hoekstra explains: ‘We want to understand what happens inside batteries so we can extract more energy, extend their lifespan, and improve overall performance. Building a functional battery pack is relatively simple, but maximising its efficiency, durability, and safety is far more challenging. This requires a deep understanding of battery complexity. If you're not Tesla or Volkswagen, you likely don’t have this specific expertise in-house. Many of our partners are smaller OEMs in the heavy-duty sector, including manufacturers of trucks, buses, and marine applications. We also collaborate with partners in non-road mobile machinery, such as excavators, wheel loaders, and other construction equipment. Due to nitrogen regulations and local emission restrictions, the Dutch construction sector is increasingly transitioning to electrification. These industries typically use large battery packs in small production volumes, making optimised battery use crucial for performance improvements. In such specialised applications, there is significant potential for efficiency gains.’

Sign up for our webinar

Join our Meet the Expert session to discover our latest research and development on Battery Management technology, our vision on the future and how collaborations lead to joint improvement. Together towards sustainable HD transport.

Valuable for TCO

To better understand battery performance, TNO is developing advanced Battery Management Systems (BMS). Feye Hoekstra explains: ‘A BMS monitors how a battery is being used and assesses its current status. Initially, simple models provided minimal insights, but with increasingly sophisticated chips and more accurate models, these systems have become highly valuable. For example, during fast charging, you need to determine the maximum charging speed that won’t degrade the battery cells. At its most basic level, a BMS ensures the battery operates within safety limits. A slightly more advanced function is determining the remaining energy level, but it becomes even more complex when assessing a battery’s State of Health (SoH) — a key factor in predicting its lifespan and identifying ways to extend it. In this sense, a BMS is a crucial tool for reducing the Total Cost of Ownership (TCO). If you can extract more energy from a battery, a smaller battery pack may be sufficient to achieve the same range. Additionally, extending battery life further reduces overall costs.’

Battery fire safety

TNO collaborates with manufacturers to enhance Battery Management Systems (BMS), including testing sensors that predict thermal runaway—a critical safety risk in battery systems. Feye Hoekstra explains: ‘For one of our partners, we conducted thermal runaway experiments to test new sensors designed for early detection. Using controlled stress tests, we deliberately push batteries towards ignition, such as by overheating them. This process generates valuable data patterns that can be integrated into detection algorithms, enabling earlier and more reliable safety measures. By incorporating this technology into their BMS, companies can enhance battery safety without having to conduct complex experiments themselves.’

TNO Powertrains also works on fundamental innovations and patents in battery technology, often in collaboration with start-ups and scale-ups that are addressing specific challenges. ‘For example, in collaboration with LionVolt, a spin-off from TNO at Holst Centre, we designed a new charging algorithm for a novel battery chemistry. We then implemented and tested this algorithm on a prototype battery module developed by TNO Powertrains.’

Predicting battery life

To improve the accuracy of battery lifespan predictions, Feye Hoekstra and his team are continuously refining their models. ‘In the past, a Battery Management System (BMS) only monitored its own battery. Today, however, battery systems exchange data via the Cloud, allowing us to develop more complex ageing models. For OEMs, one of the biggest challenges in developing a new battery for a new vehicle is providing a reliable lifetime warranty. Large manufacturers can afford extensive ageing tests with endless field simulations, but smaller players often lack the budget for such costly and time-consuming experiments. Blindly relying on general estimates from battery manufacturers is not an option either. This is where our advanced lifetime prediction models provide a solution. By combining our models with real-world data from similar battery types, we can now deliver accurate lifespan predictions for new batteries in specific applications — without the need for expensive, lengthy testing.’

Preparing companies for the battery passport

Beyond technical advancements, TNO is also supporting the industry in electrification on a broader economic scale. As one of the founding members of the Battery Competence Cluster, TNO plays a key role in an innovation programme that brings together companies, knowledge institutes, and organisations to develop expertise in battery technology. The programme now has over 200 members.

One of the practical ways TNO assists companies is in preparing for the upcoming battery passport — a regulatory framework that will be crucial for traceability, recycling, and valuation of used batteries.

Feye Hoekstra explains: ‘The battery passport is essential for ensuring the responsible lifecycle management of batteries. At TNO, we are collaborating with our ICT, Strategy & Policy unit to develop a secure platform for centrally storing and retrieving battery data. The battery passport must report various key indicators, such as State of Health (SoH) and roundtrip energy efficiency. We are investigating which technical parameters are most relevant and how they can be accurately calculated using advanced algorithms. Through this initiative, TNO helps companies not only comply with regulations but also leverage battery data to optimise performance and sustainability.’

‘At TNO, we possess in-depth expertise on batteries and their performance — knowledge that remains scarce in the industry. We help companies better understand their batteries, enabling them to implement cleaner energy solutions.’

Tool provides logistical insight into grid congestion

TNO is applying its battery expertise to address real-world challenges, such as grid congestion in the logistics sector. One key innovation is the Charge Planning Tool, designed to optimise charging capacity and logistics planning.

Feye Hoekstra explains: ‘Carriers and shippers looking to electrify their fleets often face limited power connections, restricting their ability to charge vehicles efficiently. To help them make the most of their available charging capacity, TNO has developed the Charge Planning Tool—a system that integrates the charging cycles of electric vehicles into logistics planning. The algorithms behind the tool are powered by real-life data, enabling businesses to optimise energy use and charging strategies without requiring costly infrastructure upgrades. This directly contributes to smoothing the energy transition and achieving climate goals in logistics.’

TNO closes the knowledge gap

When asked to summarise the role of TNO Powertrains in the Dutch battery-electric domain, Feye Hoekstra provides a clear answer: ‘Closing the knowledge gap. At TNO, we possess in-depth expertise on batteries and their performance — knowledge that remains scarce in the industry. We help companies better understand their batteries, enabling them to implement cleaner energy solutions. We take a pragmatic approach, addressing today’s challenges in the electrification of mobility and transport. This includes developing practical solutions, such as the Charge Planning Tool, which optimises charging strategies in logistics. At the same time, our role extends beyond solving immediate issues. It is our job to anticipate future developments, prepare the market for new battery technologies, and bridge knowledge gaps within companies, ensuring a smoother transition to sustainable transport.’

Get inspired

Meet the Expert: Battery Management System algorithm development

The Hydrogen engine ignites the future and earning power of Europe

Clean and robust hydrogen engine pivotal for achieving emissions targets heavy transport

TNO helps battery and vehicle sector with future-proof implementation of battery passport

Optimal charging planning for logistics service providers considering grid congestion