Protection materials

In mission and weapon-platform development, lighter is always better, with a fresh incentive by the growing need for increased sustainability and reduced ecological impact. With our clients, the national and international MoD’s and defence industries, typically trying to slash their carbon footprint by upwards of 25 per cent, limiting fuel consumption by reducing weight is a natural objective.

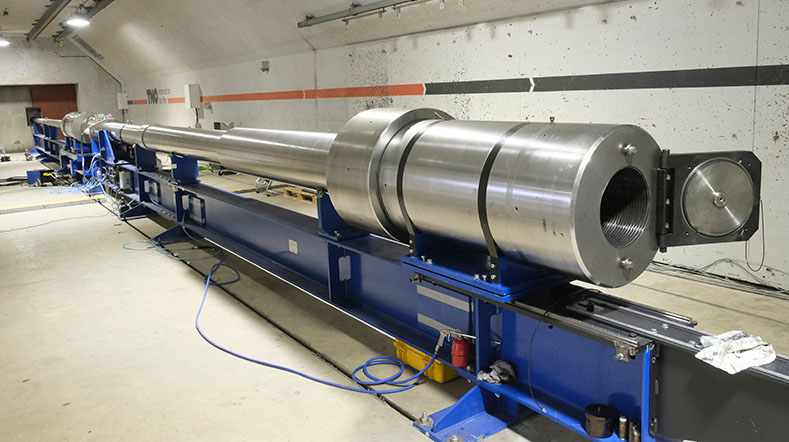

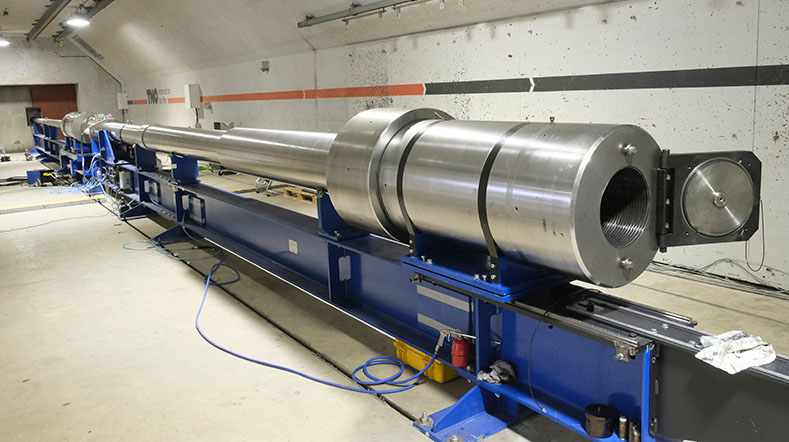

TNO has been working on the trade-off between weight and protection level for many years – and will continue to do so for many more to come. With composites, we have demonstrated that the same level of protection can be achieved on a military vehicle whilst yielding a weight reduction of 20 to 30 per cent. Already, TNO was able to demonstrate this with some impressive full-scale testing in 2019.

Shift towards composites

TNO covers a broad area of research and testing, mostly related to materials and their applications in protective equipment. Traditionally, protective equipment has always been heavy because of its very nature, aiming to stop kinetic threats. In the past such protective equipment was mostly made of metals and ceramics, the latter of which remains an important focus material for TNO.

However, in response to an increasing demand for lighter materials, our portfolio is now shifting perceptibly towards composites. These are typically carbon- and glass-fibre thermoset composites, but thermoplastic variations are likely to be considered in the near future.

Products and services

Our activities can be clustered in four categories:

- additive manufacturing (3D printing)

- composites

- ceramics

- advanced materials, e.g. Meta Materials.

We offer a range of products and services within these categories, including material or concept development. For example, the composite material we developed in-house and patented in 2019. We also carry out product evaluations for national authorities and commercial clients. In the field of additive manufacturing, we provide support in the implementation of this novel production technology in the military maintenance infrastructure and supply chain.

Terminal Ballistics

Another key research area for TNO is terminal ballistics, the physics behind the interaction between a projectile and a protective material. Basically, we investigate how a bullet, for example, reacts on finding a piece of armour in its path. Another challenge is that relating to the availability of materials. The prices of some exotic material compounds can be very high because the base materials are in short supply.

Customer focus

Our principal clients in this area range from Ministries of Defence (MoDs) to the defence industries that serve them. We are a trusted partner of the Netherlands Ministry of Defence, as well as the MoDs of many of our NATO partners.

In the defence industry, our clients include the companies that design and build military vehicles and protective equipment, including ballistic vests and helmets. We also collaborate with material development companies, as well as knowledge and education institutes throughout Europe.

Get inspired

How the use of passive radars and satellite signals can detect and identify aerial threats

Responsible for safety: the crucial role of the range operator in bulletproof protection

Is the race between protection and weight of Defence vehicles changing?

Prevent mild brain damage (mTBI) in the military? TNO is helping to build knowledge

How does TNO help protect us from hypersonic weapons?