Process safety and dangerous goods

Chemistry can be hazardous and involve dangerous reagents, energetic reactions and/or risky process conditions. The industrial production of chemicals, their storage, transportation and end-use must occur in a safe, reliable and efficient manner. For this reason, understanding the chemistry and behaviour of a dangerous substance is paramount; this is the goal of our work.

TNO has contributed to the development of many tests and criteria in the field of hazardous chemicals. TNO’s so-called “Coloured Books” are used around the world as standard reference material for safety studies and as the basis for software models.

TNO Process Safety Solutions applies its recognized hazardous chemistry expertise, explosion safety knowhow and highly specialist infrastructure to support the safe chemical handling and improvements to process performance.

Chemistry under Extreme Conditions

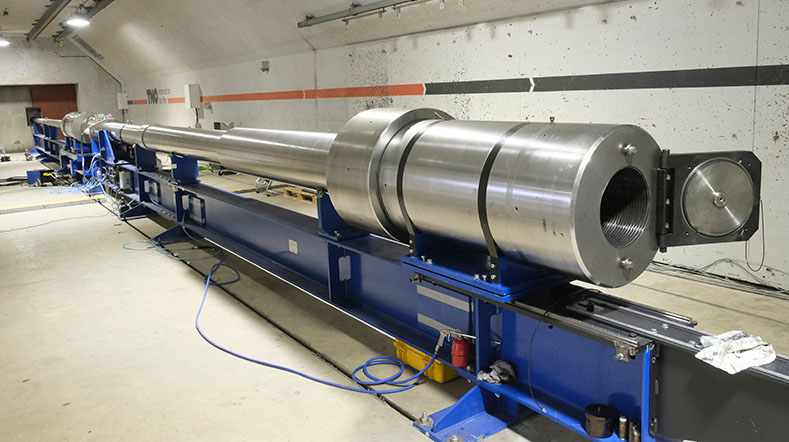

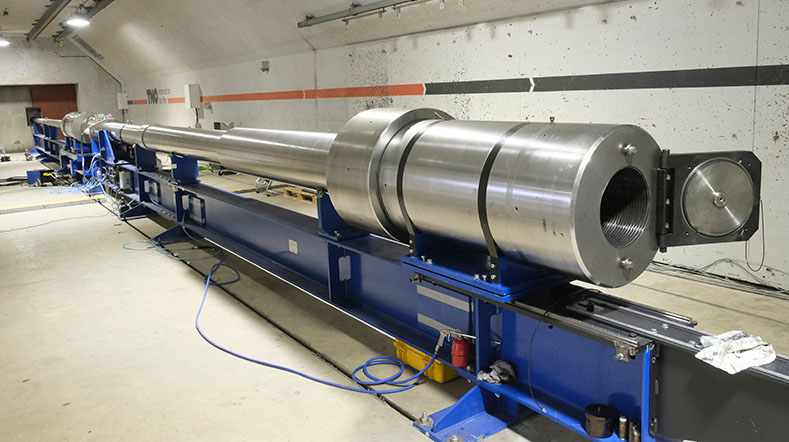

Unique problems require unique expertise and capabilities. TNO Process Safety Solutions has a proven track record in the customized testing of processes and materials under extreme conditions. We can help you identify whether certain materials, equipment or processes can handle extreme temperatures, pressure or explosions. Our fume hoods, analysis equipment and testing infrastructure are placed in fortified bunkers. This enables us to perform experiments under extreme conditions such as temperatures ranging from -180°C to 1000°C, pressures ranging from 0 to 2000 bar, from no hazard to highly explosive and from lab scale to pilot scale. Our expertise includes:

- hydrogen, ammonia, hydrocarbons, reactive chemicals, composite materials

- experiments in cryogenic conditions, high temperatures, high pressure

- permeability and compatibility tests with high pressure and/or hazardous chemicals

- explosion safety

- runaway reactions

This broad range of possibilities enables our customers to develop new materials, novel applications, explore innovative production routes or intensify their current processes without compromising on safety.

An overview with showcases is given in this document (pdf).

Classification and Testing of Dangerous Goods

At TNO Process Safety Solutions we have extensive knowledge of testing and criteria standards in the field of handling, transporting and classifying hazardous materials. We understand their background and can carry them out efficiently and effectively on short notice. With decades of experience in testing and classifying materials for all kinds of industries, we are able to provide sophisticated chemicals safety studies. Our activities include:

- classification of dangerous goods (according to UN Manual of Test and Criteria, ADR, IMDG code, CLP, etc.)

- thermal stability tests (DSC, TGA coupled with FTIR/MS, HFC)

- sensitivity tests (sensitivity to spark, friction, impact or detonative shock)

- detonation and deflagration tests

- response to heating or ignition under confinement (Koenen, DPVT, TPT)

- burning behaviour test

These analyses play an essential role in identifying potential risk factors related to the processing, handling and storage of hazardous materials and are key to preventing industrial, logistics and warehousing incidents. TNO Process Safety Solutions continuously applies these tests and our expertise includes materials such as:

- explosive substances and articles

- ammonium nitrate based fertilizers

- fireworks

- organic peroxides and self-reactives

- self-heating substances

- thermally instable substances

- pharmaceuticals

In addition to the actual testing, we are involved in the development of new regulations and test methods, we participate in international expert groups and we maintain a good relationship with various national research and test institutes around the world. This means we are always at the forefront of new developments and can provide the best possible support to our clients in their continuous advances.

You can see an overview of our testing capabilities in this document (pdf).

Responding to customer focus

Our broad clientele includes large chemical, food and pharma companies, SMEs, national authorities and insurance companies. We can easily adapt to the specific focus of our customers, partners and stakeholders. Our Process Safety Solutions team consists of multi-disciplinary specialists who are able to apply their expertise to find a solution to your challenge.

Get inspired

Responsible for safety: the crucial role of the shooting master in bulletproof protection

Is the race between protection and weight of Defence vehicles changing?

Prevent mild brain damage (mTBI) in the military? TNO is helping to build knowledge

How does TNO help protect us from hypersonic weapons?