Sustainable fuels from useless waste streams

Status project

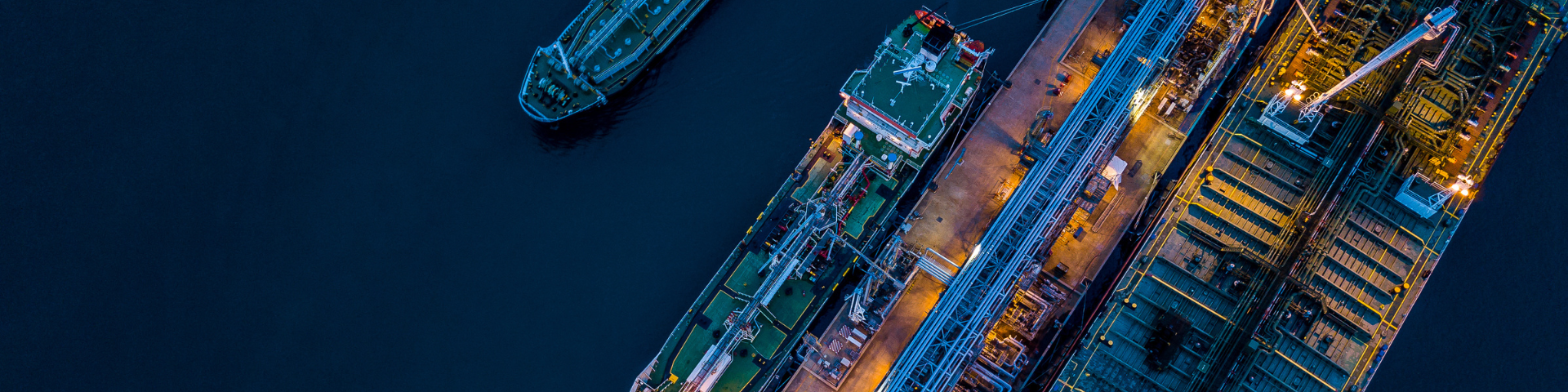

Currently running: Sustainable fuels as a solution for sectors such as shipping

In cooperation with

Consortium of 10 partners from 7 EU Member States

Producing sustainable fuels from agricultural waste streams in a highly efficient and flexible way. That, in a nutshell, is the mission of Butterfly, a European innovation project led by TNO in a consortium of 10 partners from 7 EU Member States. Sustainable fuels are a solution for sectors that are hard to electrify, such as shipping and the steel industry, but also companies and households in outlying areas.

Flexible switching

We previously developed the adsorption technology SEDMES (Sorption Enhanced DME Synthesis), which converts CO2 and green hydrogen into renewable DME in a single step. DME can serve as a replacement for diesel and LPG as a fuel for industry and transport. It is also a sustainable alternative to propane and butane gas, which are widely used in remote areas. By coupling SEDMES with TNO gasification technology MILENA, two biofuels can be made in a very flexible way: DME and synthetic natural gas (SNG). "Depending on the changing demand in certain seasons or areas, you can then switch very flexibly from one product to another," says TNO researcher André van Zomeren.

Sustainable fuels as a solution for sectors such as shipping and steel industry

Participants in the Butterfly consortium include universities from Finland, Italy, and Germany, energy company ENGIE, DME producer Dimeta, and TNO spin-off TORWASH, which processes sludge as residue from sewage treatment plants into a substance that can serve as a sustainable fuel. As with the biogenic waste streams, a useless product that would normally end up in a waste incinerator now supplies a valuable product through gasification.

"We’ll conduct lab-scale tests with a wide variety of waste streams to turn them into the sustainable fuels syngas and DME. Larger-scale demonstrations will follow. Only one party has so far managed to do this in a flexible and cost-effective way. In Butterfly, we’re going to show that it can be done."

Developing technologies further

A key partner in this project is ENGIE, which is making its Gaya platform near Lyon available for the experiments with and demonstrations of gasification technologies. There, we can contribute knowledge gained in our own laboratory and develop it further in larger-scale demos.

Basis for numerous innovations

In the first phase of Butterfly, we tested a variety of residues with the gasification technology MILENA. We also investigated the possibility of replacing steam, which is used during gasification, with hydrogen, because steam is unsuitable for SEDMES and must be dispensed with in order to couple the two technologies. Hydrogen is what is needed in the SEDMES process, while either steam or hydrogen can be used for the MILENA technology. Initial results have been successful. During 2024, a physical underground connection will be built between two TNO labs in Petten to extensively test the coupling between SEDMES and MILENA. This will be followed by tests and demonstrations at ENGIE in France.

"That connection is a long-held wish that is now becoming a reality thanks to EU funding. We bring the gas produced through MILENA to the SEDMES process. This is not only of great importance for Butterfly but also serves as a basis for many other innovations we can develop," says André.

Sufficient biogenic waste available

The EU and the Netherlands have large ambitions to replace fossil fuels with renewable ones. Agricultural waste streams and waste wood can be converted into biofuels using TNO technologies. Butterfly offers the additional advantage of flexibility, i.e. being able to switch easily between the production of DME and SNG, depending on demand at a specific time in a specific region or price trends.

"And because you can convert so many different waste streams into biofuels, you become less dependent on other energy sources or countries you would rather not do business with. We have enough biogenic waste in Europe to produce sustainable fuels on a large scale. Moreover, the technology will soon be applicable anywhere in the world where there are sufficient waste streams. This will be a major step in the energy transition.”

High-quality building blocks for chemistry

By being able to combine different technologies with all kinds of waste streams, TNO now has a platform that companies can turn to with all their questions about biofuels. In the biofuels lab, all conceivable steps in the processing of biomass and CO2 sources into sustainable fuels can be fully tested.

"In this way, we’re also laying the foundations for providing chemistry with high-quality building blocks in the future," says André.

Get inspired

Local, circular, and biobased: towards the textile industry of the future with HEREWEAR

Renewable fuels

TNO develops method to produce biocarbon

New technology combines biocarbon production for industry with negative emissions

Producing renewable DME using renewable energy and CO2