CO2 infrastructure and transport

As long as fossil fuels and raw materials are still used, CO2 capture and storage (CCS) is essential in the fight against climate change. It is also expected that CO2 storage will still be needed in the future to meet negative emission targets. Transporting CO2 from capture to storage is not straightforward. Using models and innovative test facilities, we map the unique properties and technical challenges of CO2 transport and contribute to safe, efficient, and affordable CO2 transport and infrastructure.

CO2 transport is essential for CO2 capture and storage

The energy transition demands a lot from the industry. Adopting a completely new, sustainable way of working overnight is not feasible. With Carbon Capture and Storage (CCS), we can immediately impact the CO2 levels in our atmosphere. We capture CO2 directly at the emission source and store it in deep saline aquifers or empty gas fields, where it can be stored safely and long-term.

The transport phase brings unique challenges. CO2 behaves differently from other gases like natural gas. The various transport methods (pipelines, ships, trucks, trains) require specific expertise. Contaminants in CO2 streams can cause significant damage to transport infrastructure, and phase transitions due to pressure or temperature changes must be accurately modeled for safe transport.

As a knowledge partner, TNO helps the industry, policymakers, and other stakeholders overcome these complex challenges, making it easier to deploy CCS to reduce CO2 levels in emissions and the atmosphere.

The transport chain: from capture to storage

CO2 transport begins where the capture process ends: when CO2 is captured at an industrial source, such as a cement plant or waste incinerator, and needs to be transported to the storage location. For large-scale projects, we know three methods of CO2 transport:

Pipelines are most suitable for large-scale transport, where CO2 can be transported as a liquid or gas, depending on the pressure.

Porthos and Aramis are examples of Dutch pipeline infrastructure projects for CO2 transport, where TNO plays an important role in designing and assessing the transport infrastructure.

CO2 transport over water has three variants: low-pressure, medium-pressure, or high-pressure ships. As the number of CCS projects grows, old transport ships are being adapted, and new, larger ships are being developed.

TNO can advise on developing new safety protocols and standards for ship transport. TNO can also provide advice for the direct injection of CO2 from ships into storage locations.

Trains and trucks are suitable for smaller volumes, such as waste incinerators not connected to pipeline infrastructure. The captured CO2 often needs to be liquefied first.

TNO can advise on the behavior of CO2 in different phases and conditions during phase transitions.

Our focus

To achieve safe, efficient, and easily implementable CO2 infrastructure and transport, we focus on the two-phase behavior of CO2 in transport and storage infrastructure, CO2 streams with certain contaminants, and the requirements for integrating new and existing CO2 equipment, such as compressors, valves, and pumps in CO2 networks.

Captured CO2 usually cannot be transported as is. Contaminants in the CO2 stream, such as NOx, SOx, water, and oxygen, can cause corrosion of transport infrastructure, even in small amounts. The precise effect of various contaminants is not well known.

Mixing CO2 streams from different emission sources (e.g., cement plants, energy suppliers, and waste incinerators) using different capture technologies increases complexity.

Too lenient specifications create safety risks, while too strict specifications lead to unnecessarily high costs, such as for CO2 purification or expensive pipeline materials. TNO's simulations, models, and test infrastructure help find a balance that is both safe and cost-effective.

CO2 may be less explosive than hydrogen or natural gas, but it brings its own challenges and technical requirements. Pressure changes or temperature fluctuations can cause CO2 to transition to another phase.

What if CO2 suddenly transitions from liquid to gas during transport due to temperature changes? And how can this be prevented?

TNO has advanced flow assurance models that predict how CO2 behaves under different conditions. These models help determine the temperature and pressure ranges within which transport remains safe and how much CO2 can flow through a system. In our innovative test facility, the 'Colorado Flow Loop,' we can test the phase behavior of CO2 with and without contaminants more precisely.

Existing equipment such as compressors, valves, and pumps designed for other gases cannot simply be used for CO2 infrastructure. Existing CO2 equipment is often designed for smaller-scale projects. For new equipment, we need to know what is required for safe CO2 transport. To measure this, we conduct pulsation and vibration measurements and advise on measures to safely use equipment in CO2 infrastructure.

Our approach

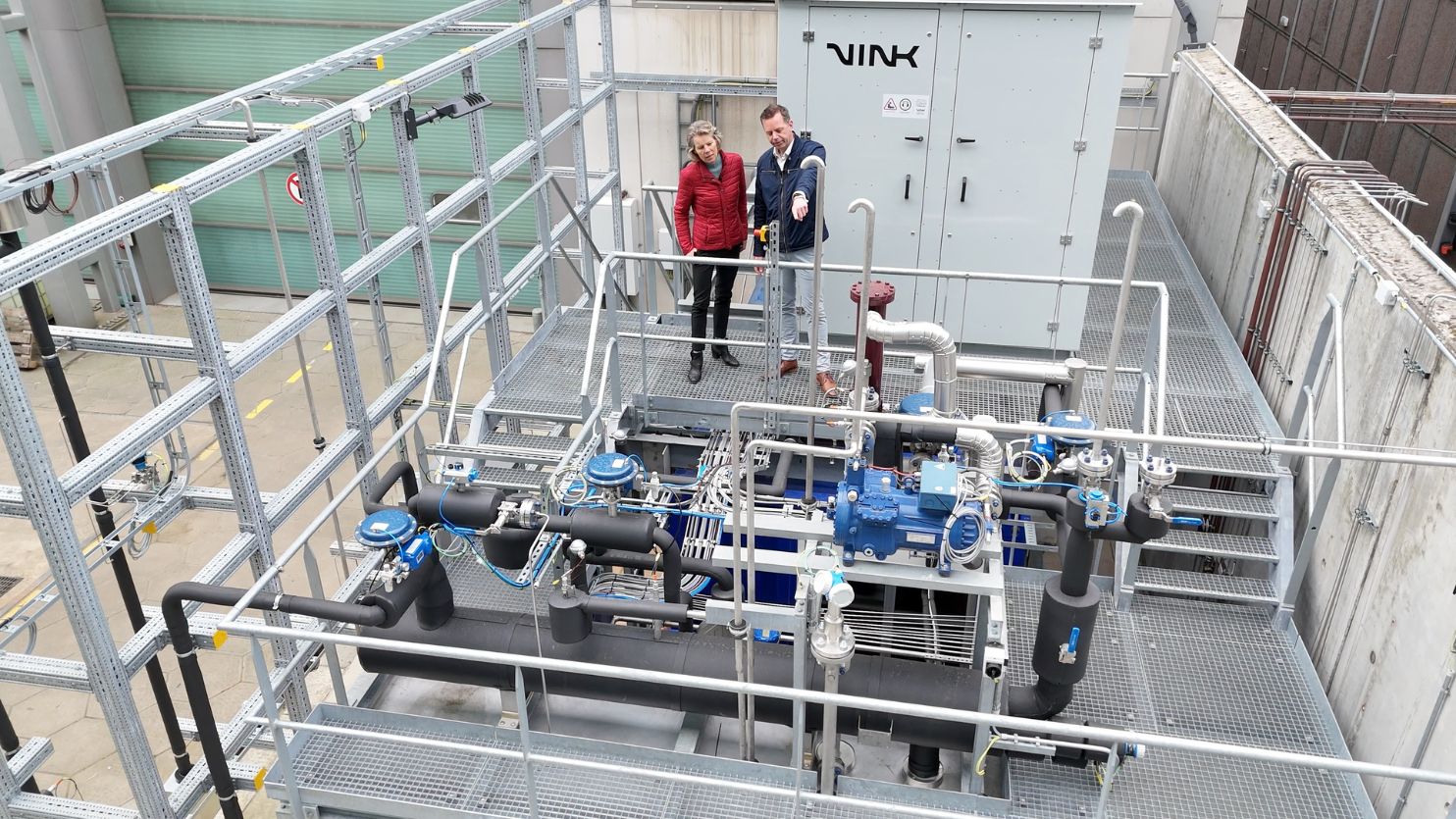

TNO's Colorado Flow Loop is a unique test infrastructure that allows us to reproduce and study the (flow) behavior of CO2 through pipes and equipment typical for CO2 transport and storage.

This facility enables us to study the two-phase behavior of CO2 streams, test the effect of contaminants on CO2 streams, evaluate material properties under different conditions, and identify safety risks.

The Colorado Flow Loop is a valuable intermediate step between theoretical research and full implementation. With the Flow Loop, TNO tests in a controlled manner what can happen in reality without first building a complete infrastructure.

At TNO, we have years of experience modeling flow phenomena, for example, for natural gas networks. Our flow assurance models for CO2 transport help predict phase transitions and determine the optimal conditions for transport. The results can then be tested in the field or in TNO's Colorado Flow Loop.

Specialized equipment is needed for efficient CO2 transport. TNO conducts pulsation and vibration measurements to determine how compressors, valves, and other components can function optimally in CO2 transport infrastructure, both for new and existing equipment.

Collaborating with TNO

In the field of CO2 transport and infrastructure, we collaborate with both national and international partners. Our projects have various forms of collaboration:

- One-on-one collaborations, for example, for organization-specific issues or when information is preferably not shared with other parties.

- Joint Industry Projects (JIPs), where we bring together like-minded partners to address shared challenges in the sector. JIPs provide more knowledge exchange and expertise, a larger research scope, often faster progress, and lower costs.

- European research projects, where we collaborate in European research consortia with sometimes dozens of partners on broader innovations in the CO2 transport chain, often (partially) funded by the European Union or the national government.

Are you involved in the development or implementation of a CCS project? As an independent research institute, TNO can help you identify and address technical and economic challenges in CO2 transport, making your CCS project faster, safer, and more cost-effective.

TNO has broad expertise that can be widely applied in the CO2 transport chain. Think of store operators preparing storage locations, compressor manufacturers, equipment suppliers, EPCs designing and building transport networks, and industrial emitters looking to reduce their CO2 emissions.

Get inspired

Energy infrastructure and transport

Tomorrow’s hydrogen production and infrastructure: building towards a secure and robust energy system

Energy system with systems integration

Expansion of energy infrastructure

European Industry & Energy Summit 2021