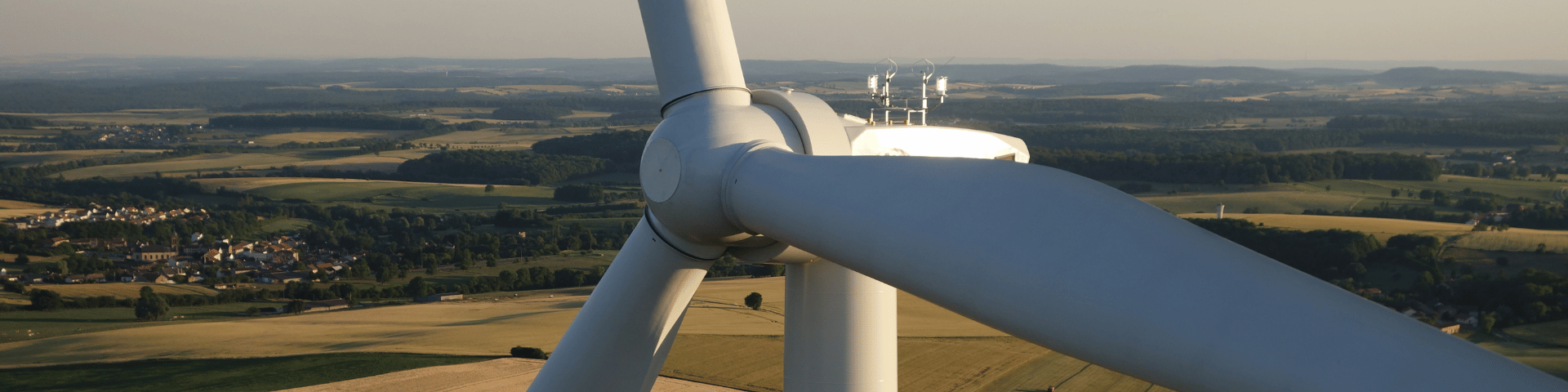

Structures for offshore renewable energy production

At TNO, our ambition is to enable safe, reliable and cost-effective offshore structures for renewable energy production. This applies to both new and existing offshore structures, pushing the existing envelopes and adapting to new circumstances and extreme environments.

Offshore structures

These structures play a important role in the energy transition of the XXI century, and it is crucial that they can operate in an optimal way. This means maximising renewable energy output with minimised downtime and optimised maintenance (time and resources). However, these offshore structures operate in extreme conditions of temperature, humidity and combined loading (e.g. strong wind and waves), which lead to complex structural degradation phenomena, such as corrosion and fatigue.

Viability of these structures will depend on optimised designs, reduced down-time, optimised maintenance resources and activities, and increased structural reliability. It is crucial to be able to understand, measure and predict the behaviour of such structures and their uncertainties, so that it becomes possible to keep their initial price at a competitive level, and to execute and plan maintenance only when and where actually needed.

An effective utilisation of different renewable energy sources, such as wind and solar, implies different types of structures. Hence, we divide our activities in three main research areas:

1. Lifetime prediction for foundations

Our focus areas are:

-

Corrosion-fatigue modelling and testing of base material and welded connections;

-

Combining data, models and probabilistics for bolted ring-flange remaining useful lifetime predictions;

-

Development of customised test setups for different scales from coupon to large components.

2. Lifetime prediction of composite blades

Our focus areas are:

-

Modelling and testing of critical wind turbine blade failure modes, such as thick adhesive bond line failure-, or delaminations, under mixed-mode loading;

-

Development of tools for damage detection in composite structures based on monitoring data;

-

Prediction of wind turbine blade remaining useful life using model updating based on data collected from operational blades offshore.

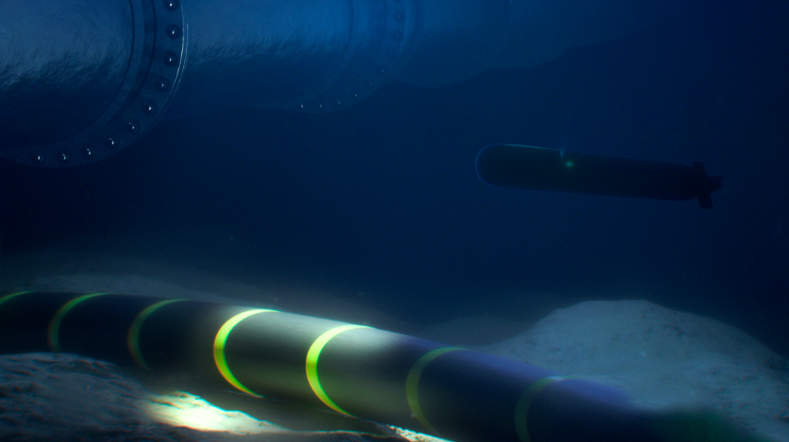

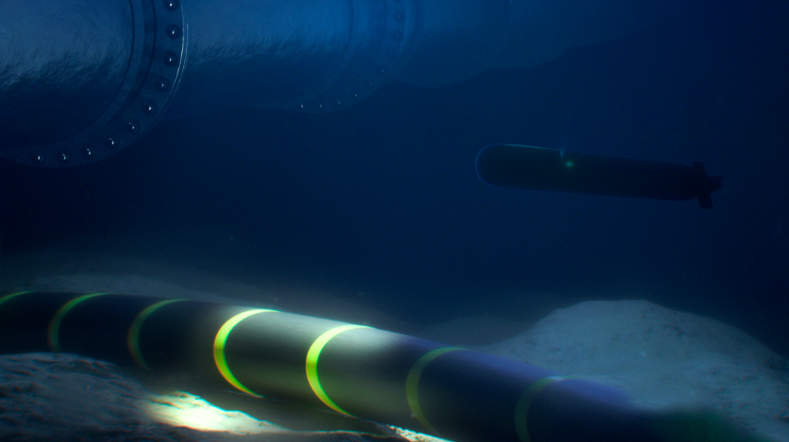

3. Large floating structures

Our focus areas are:

-

Modelling and testing of (components of) dynamic power cables for large floating solar platforms and floating wind turbines;

-

Load determination in mooring lines for large floating solar platforms and floating wind turbines.

Get inspired

Wind energy webinars

The transition to sustainable shipping

Ship materials and structures

Naval and Offshore Structures

TNO develops detection system to protect cables and pipelines on seabed