Green Transport Delta – Electrification (GTD-E)

Status project

1 October 2021 – 31 December 2024

In cooperation with

Ministery EZK, Brainport, VDL, DAF, NXP, Heliox, ELEO, Cleantron, Airborne, TU/e, UM.

To achieve climate goals, significant transitions are required both nationally and internationally in the field of sustainable transportation. The Green Transport Delta (GTD) - Electrification project has been initiated for this purpose. The project aims to develop a robust battery ecosystem in the Netherlands.

Climate-neutral mobility

The primary focus of the GTD-E project is to accelerate the transition to climate-neutral mobility, promote a circular economy, and further develop a strong Dutch (manufacturing) industry that is internationally competitive and contributes to the future earning power of the Netherlands.

How do we achieve this?

This is achieved by taking more activities in development, production, and application of batteries and charging solutions in-house and developing a unique R&D position in the field of battery-electric transportation. This is accomplished through in-depth and multi-year cross-sectoral collaboration at value chain level.

Who do we cooperate with?

Each consortium partner is a leader in the market and domain in which they are active. This includes both the international domain (e.g., VDL, DAF, NXP) and the innovative SME domain (e.g., Heliox, ELEO, Cleantron, Airborne). Additionally, the consortium includes research institutes such as TNO, Eindhoven University of Technology (TU/e), and Maastricht University (UM). VDL acts as the lead partner, with support from Brainport and TNO in coordinating the project.

For broader application and implementation of R&D developments, the consortium also involves cross-sectoral collaboration with the maritime sector (e.g., ESTFloattech, NPS Diesel) and the aviation sector (e.g., Eflight, DEAC). Bringing together the collective technological expertise and experience of the consortium partners is crucial for this project.

The battery chain is highly complex, with significant interdependencies during battery production from cell to modules to package, and during application between the vehicle, charger, and the energy grid. Only by bringing together the right players from the entire value chain can a unique R&D position and competitive position be achieved.

Impact on sustainability and digitalisation

Establishing an innovative and competitive Dutch battery value chain can significantly accelerate the growth of battery-electric transportation in the Netherlands. The introduction of a modular, bi-directional energy system, where vehicle, charger, storage, and generation are interconnected, provides a solution to seamlessly integrate electric transportation into an overloaded energy grid.

Optimisation tools will be used for energy and fleet planning. This project supports the growing demand and ambition of the Dutch mobility sector, including the automotive, maritime, and aviation sectors, to strive for sustainable transport and reduce dependence on international suppliers.

Project details

The project Green Transport Delta – Electrification is made possible with the support of the Ministry of Economic Affairs and Climate (EZK).

Project Period: October 1, 2021 – December 31, 2024

Project Budget: €36,082,844

Reports

Work package 6 of the GTD-E project (pdf) focusses on the recycling of lithium ion batteries. This report provides an overview of the developments in lithium ion battery technology in the context of recycling technologies and capacity. The composition of the components in Li-ion batteries currently being put on market as well as expected future battery technologies are described. This is done with the aim of creating insight in what materials should be taken into account in future recycling facilities. In addition, a brief market outlook shows what quantities of the different lithium-ion battery technologies may be expected to be put on market and eventually in recycling.

Work package 6 of the GTD-E project (pdf) focusses on the recycling of lithium ion batteries. This report gives a detailed description of the field of lithium ion batteries recycling in Europe, including a proposal for (a combination of) recycling technologies for a new recycling plant. The focus is on hydrometallurgical processes over pyrometallurgical processes because the former are considered to have advantages over the latter with respect to recovery of lithium (i.e., losses in the slag), energy use, and concerns over health and environmental impact. A selection of five processes, consisting of both mixed precipitation and solvent extraction processes, is studied in more detail using a semi-quantitative approach to assess the (dis)advantages of every process and come to an optimal combination of process steps.

Work package 6 of the GTD-E project (pdf) focusses on the recycling of lithium ion batteries. This report focusses on the assessment and optimisation of a pretreatment process. The process assessment is done by determining:

- The black mass recovery efficiency by setting up a mass balance for the process,

- The quality of the output materials by looking at its chemical and physical composition,

- Efficiency of the removal of the electrolyte by looking at the mass balance and analysing various output streams,

- The impact of the partial pyrolysis due to shredding of charged batteries on quality of output materials by varying the charging state of the input materials.

Additionally, the ability to increase the recovery of cathode active materials was studied by testing several extra processing steps for the residual fraction.

The main objective (pdf) of the work presented here, is to further build on the earlier published report Literature assessment of Li-ion battery recycling steps. This is done by the development of a perspective on a scalable and flexible battery recycling process by setting up a blueprint for battery recycling and evaluate it through the preliminary techno-economic assessment. The development of the methodology used in this work was a major goal of this project, with the benefit that it is also suitable to apply for alternative metal recycling processes or new iterations of techno-economic assessment with better specified information.

Get inspired

Health of electric bus batteries now measurable on-site via charger

Transition co2 neutral mobility 2050

TNO accelerates electrification of logistics and construction through a deeper understanding of batteries

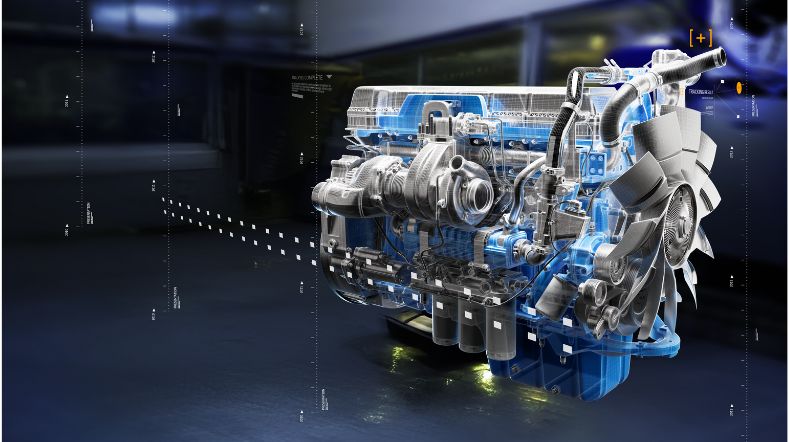

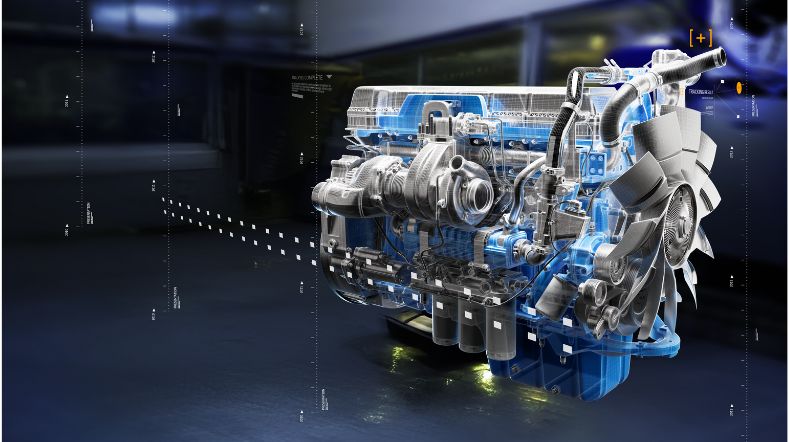

The hydrogen engine ignites the future and earning power of Europe

Clean and robust hydrogen engine pivotal for achieving emissions targets heavy transport