Hydrogen internal engine accelerates energy transition

In order to meet climate goals and to accelerate the transition to more sustainable transport and traffic, other clean alternatives such as hydrogen are needed for heavy-duty road transport and shipping, in addition to battery electric solutions. Hydrogen used directly in an internal combustion engine is a promising solution in applications where electric power is not possible or not yet sufficiently available. TNO Mobility and Built Environment is using its long-standing expertise in internal combustion engines and hydrogen to further develop and scale up this technology.

Climate challenges in road transport

In line with the Paris Climate Agreement, EU member states have agreed to emit at least 55% less greenhouse gases by 2030 compared to 1990 (Green Deal). Moreover, the EU aims to be climate neutral by 2050. The new CO2 legislation for heavy road vehicles requires emissions to be reduced by 45% by 2030 compared to 2019, and as much as 90% by 2040.

With the number of trucks that need to be electrified to meet emission targets, there is by far not enough charging capacity available, even by 2030-2035. Although battery electric vehicles are seen as the main alternative to fossil-fuelled vehicles, they are not a one-size-fits-all solution.

In order to ensure that all means of transport are powered by renewable energy by 2050, it is important to rely on a mix of sustainable technologies and energy sources. In addition to biofuels and synthetic fuels, hydrogen is an interesting alternative for (heavy) road transport.

Biofuels and synthetic fuels contribute to reducing CO2 emissions from road transport. For truck manufacturers, however, these alternatives do not count towards the European CO2 standards that apply to new sales.

Our vision

This makes hydrogen – which contains no carbon and therefore produces no CO2 emissions – the only alternative to make heavy road transport more sustainable. Hydrogen can be converted into electricity using a fuel cell or an internal combustion engine with similar efficiency. Burning hydrogen in an engine produces only water and, at most, negligible amounts of nitrogen oxides (NOx).

The hydrogen internal engine is at an advanced development stage and can use existing supply chains and service networks. This makes the technology rapidly scalable at low cost, using existing human capital. An additional advantage is that there is little need for scarce raw materials in production. Fuel cells are (still) expensive and under development for heavy mobility applications.

Our country has a significant market share and interest in the European truck sector. With the Dutch knowledge and leading role in hydrogen engines, we can secure this position for the future

Our solutions

TNO has more than 50 years of experience in combustion engines and is an expert in low- and high-pressure injection systems, such as High-Pressure Direct Injection (HPDI). This advanced injection concept ensures high specific power and efficient combustion. At TNO, we help vehicle and engine manufacturers to research and implement hydrogen engine technology.

Together with DAF, we have realised a truck with a hydrogen engine in 2021. With this hydrogen truck, which won the Truck of the Year Innovation Award in 2022, we demonstrated the feasibility of the hydrogen engine and showed its initial potential.

Unique testing facilities

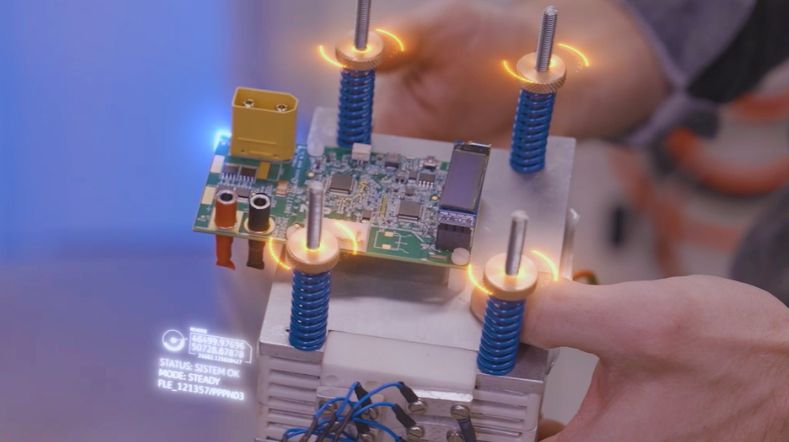

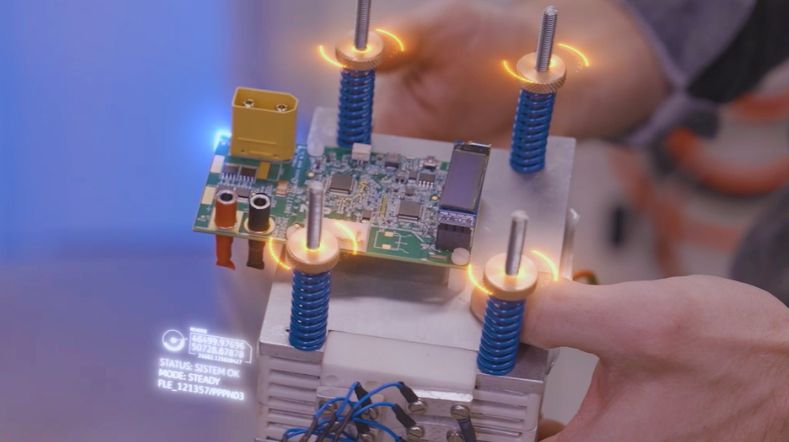

TNO's Innovation Centre for Sustainable Powertrains (ICSP) in Helmond, is firmly committed to this energy carrier, with four hydrogen engine test cells currently in operation. The ICSP is well equipped to compare and develop different combustion concepts and injection techniques in terms of performance, efficiency and emissions, and can efficiently run simulation and test programmes with our single-cylinder set-ups.

These TNO research engines offer more flexibility to make modifications faster and carry out experimental research more efficiently, with less consumption of precious hydrogen. TNO has dedicated test cells for heavy-duty trucks and marine engines. The test facilities will also be expanded in the future with two test cells suitable for high power marine applications, up to 1.4 megawatts.

Why hydrogen?

Not only in heavy road transport, but also in shipping, the hydrogen engine can be a game changer. Innovation processes in the automotive sector are generally faster than in the maritime world. Inland and coastal shipping in the Netherlands can benefit from this technological advantage.

The EARTO Innovation Award-winning retrofit hydrogen engine for ships is a promising option for existing diesel engines to achieve almost 100% CO2 reduction in the short term with limited investment.

In addition, the hydrogen engine could be used in non-road mobile machinery as a clean alternative to stationary diesel generators, earthmoving and agricultural machinery, with significant local environmental benefits.

Green Transport Delta

To further develop the hydrogen internal combustion engine for use in trucks, barges and mobile power units, TNO is working with partners in the Green Transport Delta - Hydrogen (GTD-H) project. Together with Dutch industrial partners in these sectors and other knowledge institutes, TNO is working within this project on the realisation of prototypes, closely taking into account laws and regulations and other market-specific factors.

In this way, TNO is helping the consortium partners to achieve a leading position in the energy transition. TNO is keen to engage with companies, agencies and governments that want to use the hydrogen internal combustion engine to accelerate the sustainable future of transport and logistics.

More about TNO hydrogen engine

TNO’s hydrogen internal heavy duty engine wins prize at EARTO Innovation Awards

Hydrogen internal engine accelerates CO2 reduction for heavy-duty applications

Advancing Combustion Engines for Renewable Fuels

Beyond hydrogen, several other fuels can be effectively produced from renewable resources, contributing to CO2 reduction. Consider options like methanol, dimethyl ether (DME), and ammonia. Leveraging TNO’s extensive expertise in combustion engines, we aim to optimise both new and existing engines to operate efficiently with these fuels. Notably, the maritime sector shows significant interest in methanol utilisation. Consequently, our research focuses on designing engines capable of using both methanol and diesel.

Get inspired

How far can you travel in an electric car?

National Growth Fund invests in Dutch battery consortium for heavy duty transport

TNO opens test cell for sustainable marine engines

Battery technology: 4 developments according to the Battery Lab

Fuel cells crucial for decarbonising heavy-duty transport and non-road machinery