Solar panel production back to Europe

A large fraction of all the world's manufactured solar panels overwhelmingly come from Asia. The importance of solar power for the energy transition combined with the introduction of the next generation of solar panels means it is time to bring production back to our continent. Think of modules that can be invisibly incorporated into buildings, transport and infrastructure and have a high efficiency. Plenty of opportunities for the Dutch and European manufacturing industry.

Collaboration needed

Besides obtaining high efficiencies a lot more is needed to enable large-scale manufacturing of solar cells and modules in Europe, with a strong Dutch contribution. Production costs must be reduced even further, the concept of mass customisation for integration must become a reality, with circularity as an important precondition. Achieving these ambitions requires far-reaching collaboration between knowledge institutions, companies, and governments across the entire value chain.

Regional approach in Noord-Brabant

The Noord-Brabant region is already working hard to realise this innovative manufacturing industry. The Brabant Development Company (BOM), knowledge institutions and companies are developing concepts, supported by the province of Noord-Brabant, to realise factories with the latest technology in this area. We are building further on ambitious innovation programmes and this stands alongside ambitious plans such as the major consortium of Dutch solar companies SolarNL. TNO helps companies in the manufacturing industry develop and manufacture innovative products, improve existing products or processes and enter new markets.

Webinar: Solar energy in Brabant

The province of Noord-Brabant is bringing back large-scale solar industry to the Netherlands. Goal: a 2 GW factory by 2027-2028 with new solar technologies. Curious about the opportunities for the manufacturing and building sectors?

Also watch the webinar 'The Next Generation of Solar Technology'.

From importer to exporter

A new generation of solar modules, to which TNO is currently making major contributions, will make the difference in the next decade. Simple, low-cost fixed panels will make way for new types of solar panels that are almost or entirely invisible and can be incorporated in all kinds of materials in any desired size and shape, making them easy to integrate into roofs, façades, windows and cars. There will then potentially be a lot more surface area available for generating energy.

Mass customization – mass production of tailor-made products – is the future of integrated solar power. Creating a PV ecosystem to manufacture these high-end products in Europe, with the Netherlands as an important supplier of knowledge, equipment, and semi-finished products, but also of the final products, will make it possible to tap a broad market. From being an importer to having opportunities for exporting.

Smart combinations of solar cells and recycling

Large-scale manufacturing of cells and modules in the Netherlands is possible. Our strength lies in creating innovative concepts that companies can further industrialise and then market. TNO has a unique knowledge position as regards combining solar cells into a solar panel in any desired shape, size, or colour and incorporating it into construction elements.

Strategic value chain

The European Commission has identified the solar energy sector as a strategic value chain. Solar PV makes an important contribution to achieving our climate goals. It is therefore important that we are not dependent on certain countries or regions. Producing close to home avoids shipping of solar panels across oceans, which reduces pollution and transport costs. The energy mix in Europe is also cleaner than in many other regions of the world, which further improves the already small carbon footprint of solar panels.

Moreover, we have everything here: high-level knowledge, innovative strength in innovation, and cutting-edge companies, which will enable us to become a major player again in the production of solar cells and modules.

Accelerate and scale up solar energy

The first steps have already been taken with the launch of the European Solar Initiative, supported by the European Commission. The motto is ‘accelerate and scale up’ and bring back manufacturing to Europe. Companies in various European countries are already expanding production of solar cells and solar panels, and new companies are starting up production.

Staying ahead of the curve

The Netherlands has long been a leading developer of innovative technologies in the field of solar energy. We‘ve pioneered industrially scalable new concepts developments. Circularity, aesthetics and safety are prerequisites here.

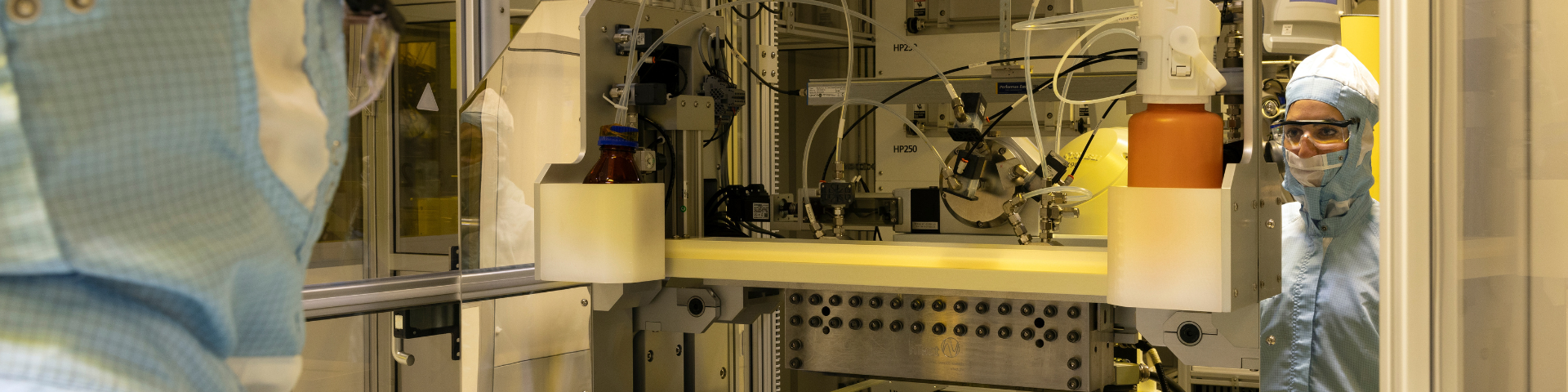

TNO has unique lab facilities to develop and test deposition technologies such as atomic layer and pulsed laser deposition (ALD and PLD), as well as low-pressure and higher temperature chemical deposition (PECVD and LPCVD). These technologies enable ultra-thin functional layers to be applied to cells to optimise performance. Layers are being developed for higher conversion efficiency, but also for protection to improve reliability. In this way, we support companies in the manufacturing industry to develop and manufacture innovative products, to improve existing products or processes, and to enter new markets.

At the same time, the Netherlands and Europe need to optimise the performance of solar cells and modules. TNO is strongly committed to the combination (a stack) of thin-film perovskite and crystalline silicon, called a tandem solar cell. We continually succeed in pushing the boundaries and increasing the maximum power output. This now achieves efficiencies of over 30% on a small scale.

In addition to tandems of perovskite combined with silicon cells, it’s also possible to make tandems of perovskite solar cells. The individual perovskite solar cells then differ in composition and therefore in colour sensitivity. This enables a better use of the energy from the solar spectrum.

In the long term (beyond 2040), tandems comprising stacks of multiple perovskite cells will enable conversion efficiencies beyond 40%. We’re currently working with Dutch universities and companies on new generations of tandem solar cells, both a stack of two cells and a stack of multiple cells. All kinds of new functional thin layers are being developed to further optimise performance.

Together with industrial partners, we‘re developing a concept for solar panels in which all components can ultimately be recycled. In the EU alone, currently around 4,000 tonnes of solar panels are not completely recycled annually. We’ll solve this problem with fully recyclable solar panels. In short, we as a country can contribute a lot to creating a flourishing solar energy industry in Europe.

Get inspired

Building fires with solar panels mapped for the first time

New multifunctional solar window generates energy by reflecting light

Webinar: Solar energy in Brabant - Building a sustainable future for Europe

Carbon footprint floating solar energy systems similar to land systems

Reduced energy yield due to rapid shading of solar panels by wind turbines