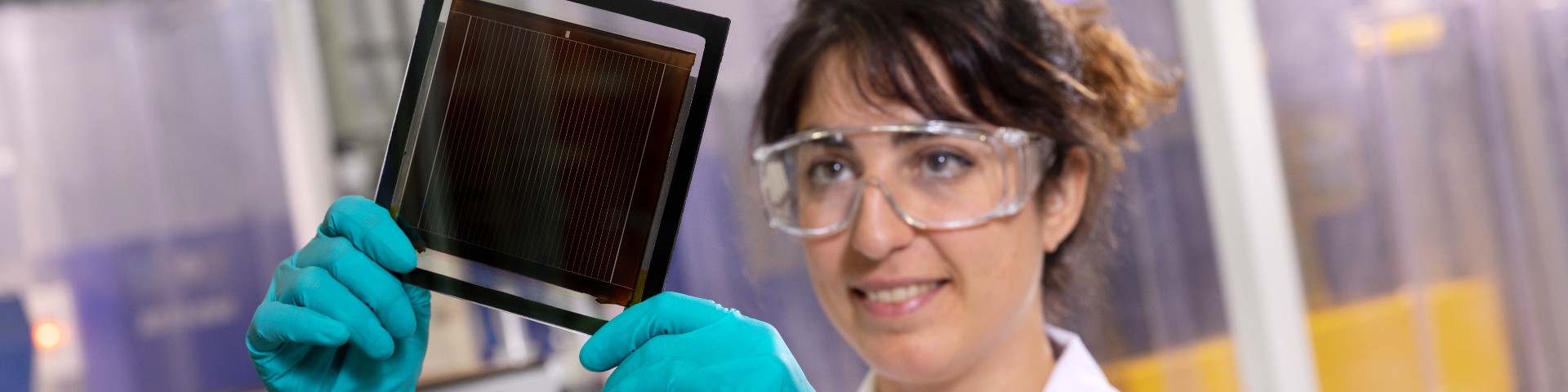

Roll-to-roll perovskite solar cells technology

Part of bringing integrated solar modules on the market before 2030, is improving the perovskite solar cell technology. In order to integrate photovoltaics (PV) into buildings, infrastructure, and transport, solar modules based on the raw material perovskite need to be available on a large scale, with high efficiency and reliability.

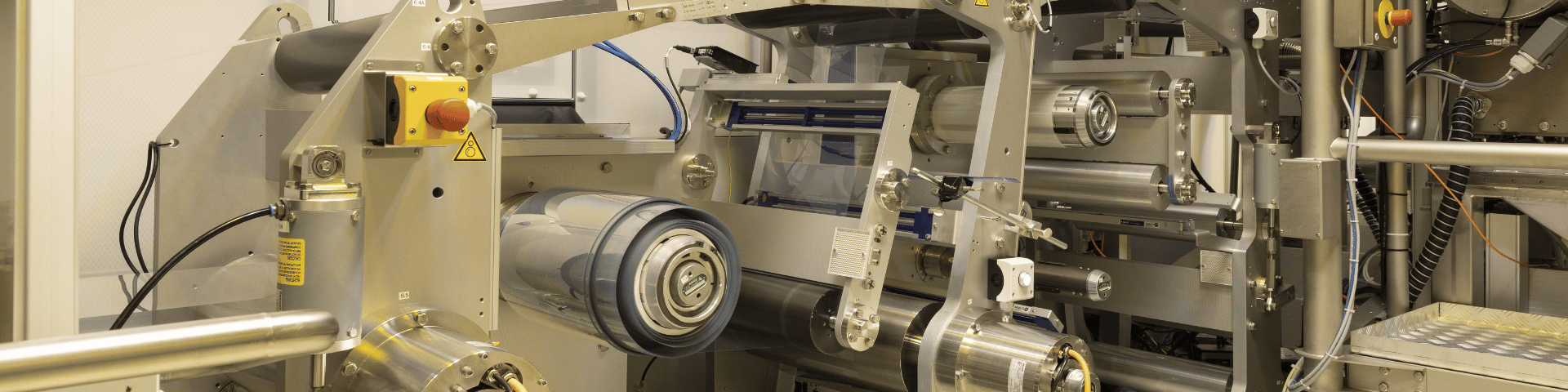

TNO is working in several project on this topic to finalize the blueprint for roll-to-roll processing of perovskite solar cells and mass customization. Some important projects and milestones TNO is working on.

Large area uniform industry compatible perovskite solar cell technology

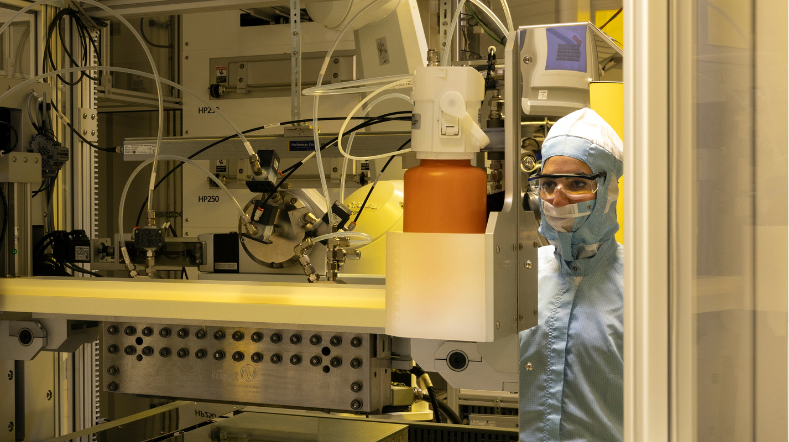

In the Horizon Europe project LUMINOSITY, partners aim at leveraging the flexible perovskite solar cells technology to commercially relevant production scales, using established industrial processes. The consortium encompasses the full value chain from research and technology developers, equipment manufacturers, suppliers, and industrial end-users.

The objective of the project is to demonstrate roll-to-roll (R2R) processed photovoltaic (PV) module with a target power conversion efficiency of 20% at a target area of 900 cm2. This will overcome the efficiency gap between lab-scale and fab-scale processed devices. One of the unique points of this work is the commercial substrate foil based on aluminum with fluorinated-tin-oxide electrode layer, which is an intellectual property of HyET Solar, the end user in the consortium.

By using this substrate foil, LUMINOSITY will alleviate the bottlenecks related to limited process window of typical polymer substrate foils – such as high temperature processes for processing high quality nickel oxide charge transport layers to reach stability, efficiency, and lower environmental impact, while keeping the flexibility.

LUMINOSITY targets to achieve operational stability exceeding 20 years that rivals the lifetime of current commercial thin film PV technologies, while ensuring and environmental feasibility, substantiated by comprehensive life cycle and techno-economic analysis.

Solar PV manufacturing industry back to Noord-Brabant

Check out the Brabant project in which we also use roll-2-roll perovskite solar cell technology.

Webinar: Solar energy in Brabant

The province of Noord-Brabant is bringing back large-scale solar industry to the Netherlands. Goal: a 2 GW factory by 2027-2028 with new solar technologies. Curious about the opportunities for the manufacturing and building sectors?

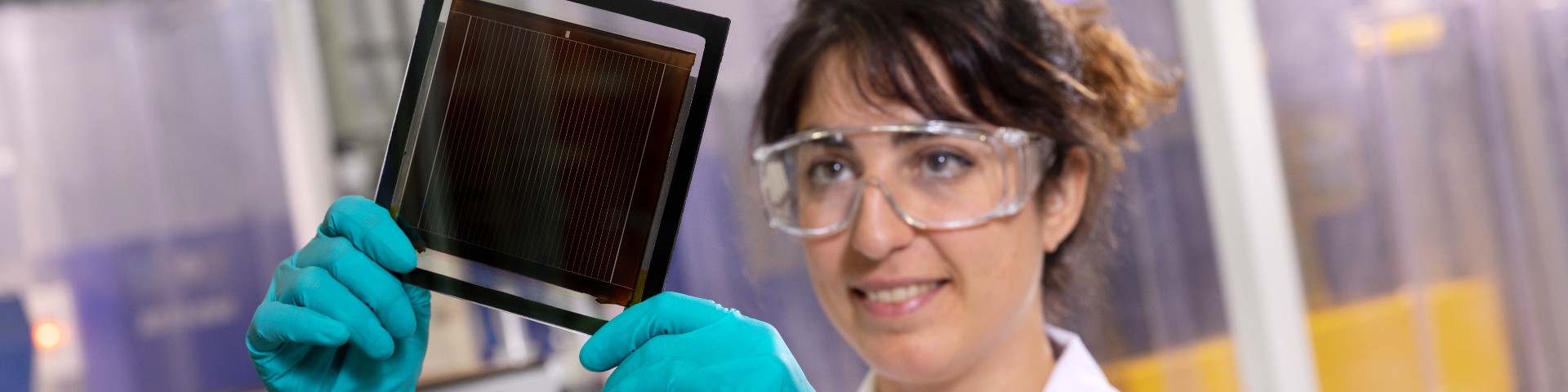

Flexible perovskite solar cells with carbon electrodes

Several advantages arise from the incorporation of carbon electrode in the perovskite solar cell architecture such as reduced material cost, improved device stability and simplified device fabrication process as well as lower emissions. Thus, the primary objective of the Horizon Europe project PEARL is to realize flexible perovskite solar cells processed with industrially viable, scalable and environmentally sound methods, showing long term operational stability surpassing the IEC standards, efficiencies beyond 20%, lowered production costs and minimal emissions. To reach these objectives, PEARL is focusing on the development of planar conventional and new device architectures utilizing low-temperature carbon pastes as the top electrodes aiming to the emerging markets of building integrated photovoltaics (BIPV), vehicle integrated photovoltaics (VIPV) and internet of things (IoT).

Printed perovskite solar cells for lare area user applications

A key challenge of perovskite technology is replication at large-scale as there is a substantial difference in performances between small-area cells (lab-scale) and large-area modules. Project PERSEUS is designed to establish a foundation for perovskite production and application development within Europe. The project will develop and demonstrate 3 different large area perovskite architectures that offer broad adoption potential across multiple industries such as floating photovoltaics, building integrated and applied photovoltaics, agri-photovoltaics and urban photovoltaics.

Upscalable functional layers and encapsulants for R2R compatible perovskite PV manufacturing

A process validation with industrially relevant equipment that is scalable to roll-to-roll (R2R) manufacturing for efficient and stable packaged perovskite PV cells has not been shown yet. In the project ULTIMA partners aim to validate processes in industrially relevant equipment for R2R compatible manufacturing and packaging of perovskite cells by using R2R compatible coating processes at sheet-to-sheet (S2S) processing scale. ULTIMA aims to develop a coatable & curable encapsulant material and soft sputter processes for charge transport layers, which may be scaled up to R2R scale. ULTIMA also sets the definition and design specifications of such R2R process tools and these results could be expoited by future work after ULTIMA.

Get inspired

The next generation of solar technologies

Solar panel production back to Europe

Solar panel production back to Europe

Perovskite solar cells

Affordable, tailor-made solar energy on a large scale