New research on blade tip improvements

Status project

2020 - 2024

In cooperation with

GE Vernova & LM Wind Power

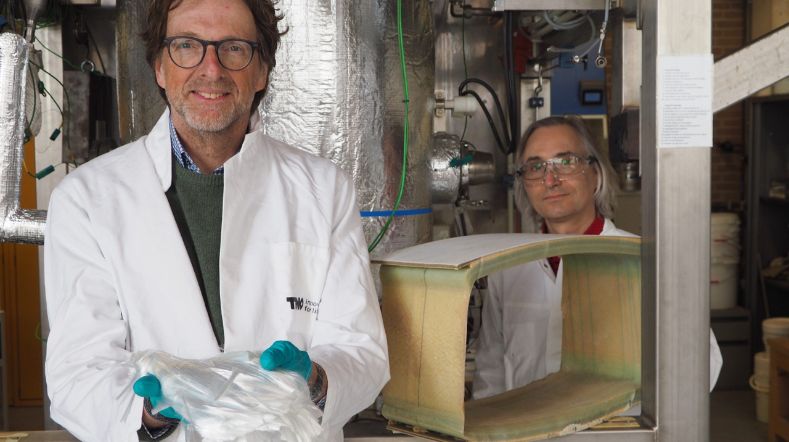

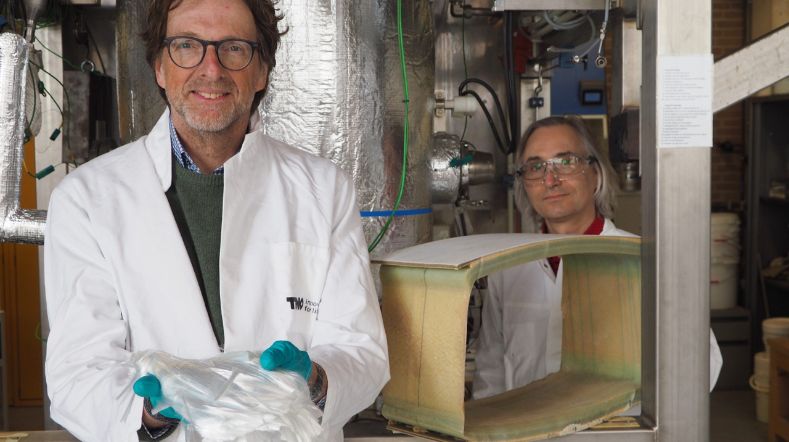

A consortium of TNO, GE Vernova, and LM Wind Power have developed technologies and design methods for more efficient operation of next-generation wind turbine rotors, wind farms with large rotor wakes and have demonstrated them in the field. This has been done in the TIADE project (Turbine Improvements for Additional Energy).

Testing on the wind turbine

In this project, researchers tested the developed innovations on the large-scale 130 m diameter wind turbine, in Wieringermeer, Netherlands. The turbine is powered by two-piece blades, which allows the outer 12 m of the blades to be replaced by several innovative tips.

"Innovations in wind turbine blades are essential to make renewable wind energy even more affordable." Peter Eecen, R&D Manager at TNO Wind Energy.

We are proud to have validated blade innovations and aerodynamic simulation tools in the field, together with GE Vernova and LM Wind Power. Thereto, we used advanced measurement techniques in a unique setup that combines detailed wind inflow measurements and unsteady pressure measurements on the blade." Peter Eecen, R&D Manager at TNO Wind Energy.

"Our revolutionary two-piece blade design has helped us drive down the levelized cost of energy. Here, in this project, we have applied new technology to significantly increase speed and reduce cost associated with testing and validation," said Ben Hendriks, Chief Engineer Turbine System Integration at LM Wind Power.

Innovative add-ons on wind turbine blades

Various innovative blade add-ons, such as spoilers, serrations, vortex generators, ‘turbulators’ and blade tip improvements are validated using advanced measurement techniques. The results will accelerate widescale application of rotors with higher annual energy production and thus a considerably lower cost of offshore wind energy.

These solutions can be applied to newly manufactured wind turbines in the factory, but they can partly also be retrofitted to existing offshore wind farms.

The consortium comprising of TNO, GE Vernova and LM Wind Power was established in 2020 to test new research on blade tip improvements. The TIADE project was carried out with partial funding from the ‘Topsector Energiesubsidie’ of the Dutch Ministry of Economic Affairs.

Download the final report here

Get inspired

Improving wind turbine maintenance with the sensor installation robot

Project launched for recycling wind turbine blades

TNO research leads to better damage prediction for offshore wind turbine blades

Better damage prediction for wind turbine blades through unique weather measurements at sea

First study on public perception of wind turbine circularity