Wind farm control to boost wind farm performance

In a wind farm, turbines affect each other through their wakes. The wake refers to the altered wind after flowing through a wind turbine. As one turbine extracts energy from the wind, the wind speed decreases and the turbulence intensity increases, leading to power losses and higher loads on the wind turbines behind it.

Increase performance with active wake control

It’s still common practice to operate wind turbines individually. This triggered us to develop a cooperative approach called Active Wake Control. It’s a family of methods to operate the individual wind turbines within a wind farm in a coordinated way to achieve a common target. As a result, it boosts the annual energy production, extends turbine lifetime, and contributes to lowering the levelized costs of wind energy. Recently, TNO has developed a unique methodology to validate benefits from wind farm control. It has been applied to assess the benefits from an offshore wind farm pilot project campaign.

Learn more about Active Wake Control?

Read the report: 'Active Wake Control Validation Methodology'

How active wake control can be achieved

Active Wake Control can be achieved in two ways: by down-regulating upstream wind turbines to increase the wind velocity in their wakes (induction control), or by misaligning the upstream turbine rotors with respect to the wind direction to steer wakes aside from downstream turbines (wake redirection).

Steering the wakes in a wind farm

Wake redirection is usually more beneficial than induction control, but also has a more pronounced impact on the turbine loading. Therefore, TNO has been studying in depth the impacts of Active Wake Control on both annual energy production and structural loads. The results are good: higher loads for upwind turbine during yawed operation are more than compensated by lower loads when that same turbine would be operating in the wakes of others. Overall the fatigue loads decrease under wake redirection control, while at the same time up to 1% energy production gain (AEP) is realised.

Validating offshore full scale test fields

As the technology matures, test fields have gathered momentum and proved the added value of the technology. TNO has developed a validation methodology that only makes use of data from the Supervisory Control and Data Acquisition (SCADA) system, which is commonly available for commercial wind farms. The measurements from wind turbine sensors are used to quantify the impact in increased Annual Energy Production (AEP). Furthermore, benefits at the turbine level can be investigated. The developed validation methodology has been designed to be applicable to wind farms with different layouts.

Learn more about Wake Model Farmflow?

Read the report: 'Farmflow: extensivly validated and dedicated model for wind farm control'

FarmFlow simulation showing the wakes of 4 large wind farms at the Borsele site

Get inspired

First study on public perception of wind turbine circularity

Wind energy webinars

X-ray drone technology and digital twin to detect sub-surface defects within turbine blades

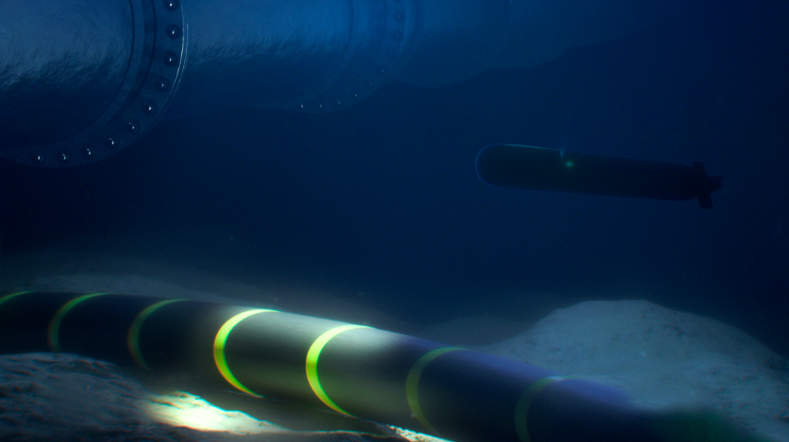

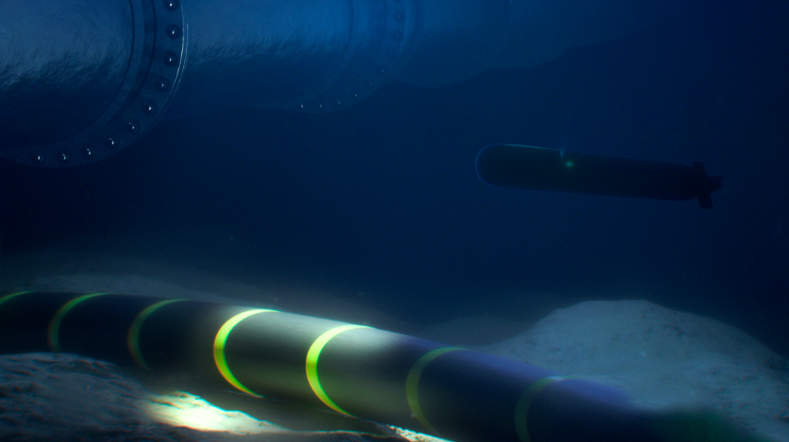

TNO develops detection system to protect cables and pipelines on seabed

Reduce Europe’s dependence on Chinese wind power and electrolysers