Silicon solar panels and circular design

We’re increasingly generating energy from the sun. There’s currently more than 14 gigawatt peak (GWp) of installed solar energy capacity for electricity generation in the Netherlands, and this can be increased to 50 GWp by 2030 and 200 GWp by 2050. Solar power is usually generated by silicon photovoltaic cells (PV cells).

For solar energy to be produced on a large scale, it’s essential to have low costs, high efficiency, and a long lifespan. We also want solar panels with circular design.

New concepts

We’re collaborating with partners to develop new solar panel concepts. With new materials, we aim to improve lifespan and aesthetics. This will enable us to develop visually attractive modules with a high energy yield. To this end, we combine knowledge of technologies, processes, and materials.

Bifacial solar panels

Solar panels normally capture sunlight on one side only. We were among the first to develop bifacial solar panels, which are now being used on a large scale. They provide 10 to 20% higher energy efficiency than standard panels that collect sun on one side, depending on environmental reflection. But the manufacturing costs are comparable, so with the right application, bifacial solar panels provide lower costs per kilowatt hour. For example, on large flat roofs, inland waters, the sea, or farmland, where crops grow or cattle walk between the rows.

Technology on the backs of panels

We’re also working on back-contact silicon solar cells and modules, together with partners in science and industry. In this case, the electrical connections are made at the back of the cells. The metal covering at the front is therefore partially or completely absent, so that the metal patterns are barely visible, if at all. This eliminates or reduces shading losses and minimises resistive losses.

Improving back-contact technology

We’re optimising this technology with industrial partners, including manufacturers of materials, machinery, cells, and modules. In addition, we’re working on the resulting products, for example for integration into buildings and cars.

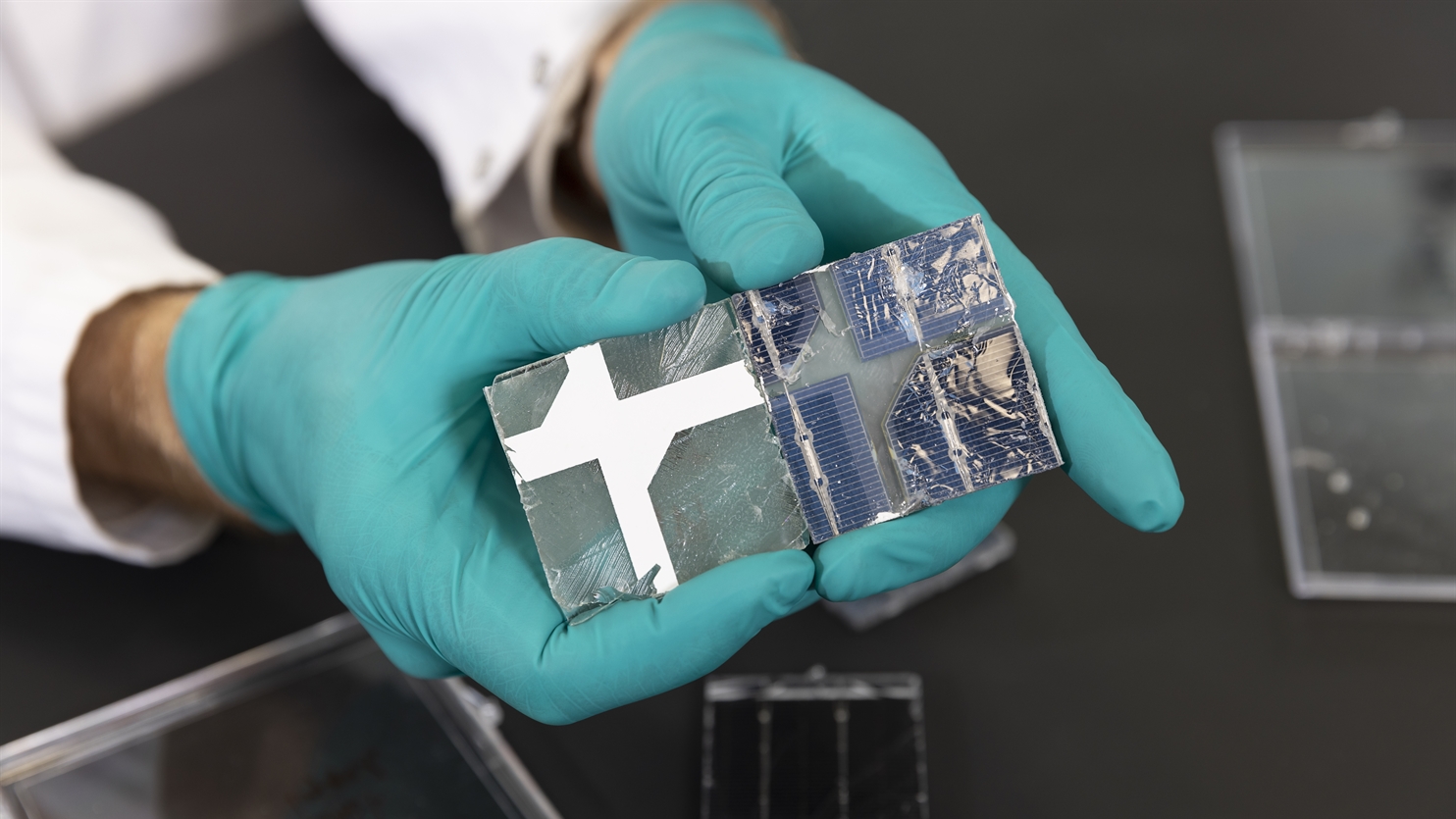

Circular design

Solar panels are designed to last, but we also want them to be easy to take apart at the end of their service life. Parts can then be replaced or valuable materials, such as silver and the silicon cell, can be recovered. To this end, we’re working with partners on developing materials and manufacturing processes that will make it easier to reuse the panels, such as the use of a special adhesive layer. This panel is equally robust in use, but during decommissioning, a specific treatment is applied, so that the various materials of the panel are separated.

Sustainable materials

Solar panels currently on the market may contain rare or harmful substances such as silver, indium, lead, or fluorine. With partners, we’re investigating how to replace these substances as far as possible with widely available and non-harmful materials that still perform just as well.

Webinar on solar energy technology

Find out more about solar energy and current technological developments in the webinar ‘Innovations in solar energy technology’.

Get inspired

Webinar: Solar energy in Brabant - Building a sustainable future for Europe

Carbon footprint floating solar energy systems similar to land systems

The next generation of solar technologies

Solar panel production back to Europe

TNO's view of 2030: using every surface for solar power generation