DEPLOI: Geothermal drilling using the ‘steel shot’ drilling technique

Status project

Since 2021 – present

In cooperation with

Canopus and many partners

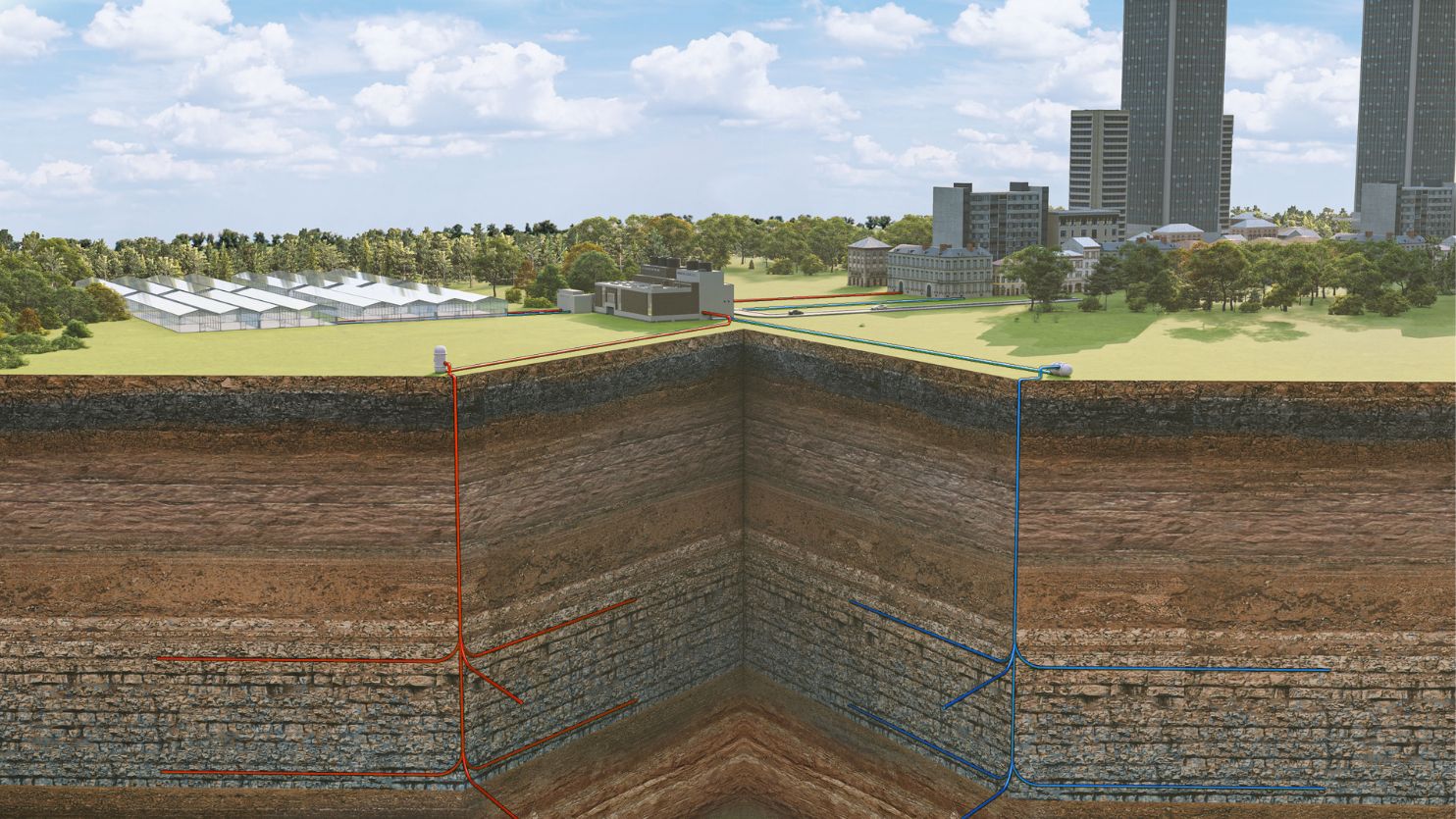

Improve robust and safe geothermal production at lower costs with advanced directional drilling technology is the goal in the DEPLOI project: DEmonstrate Production enhancement with LOw cost side track drilling. Together with European partners, TNO and the Dutch drilling specialist Canopus started the project co-funded under the Dutch Top Consortium for Knowledge and Innovation (TKI) Geo-energy. A Dutch government subsidy scheme that stimulates the development of innovations of sustainable, reliable and affordable energy systems.

New drilling technology to increase geothermal reservoir productivity

In the Dutch Rijswijk Centre for Sustainable Geo-energy (RCSG) the Canopus directional steel shot drilling technology has been researched and tested at relevant down hole conditions with the unique test facilities at the centre. This innovative technology is a possible breakthrough to enhance geothermal energy production at lower costs.

The oil and gas industry uses the concept of drilling branches or 'horizontals' out of the main bore into the reservoir to enhance the production. Unfortunately, the present horizontal drilling technologies are hardly used for geothermal drilling because of their cost and directional limitations.

Higher production with vertical wells

The new steel shot drilling technology has the potential to increase production at much lower cost compared to a vertical well.

Multiple long horizontal wells will also increase the chance of finding favourable reservoirs for sustainable production, which is currently one of the biggest risks for geothermal projects worldwide. The new drilling technology can also drill much more energy effective closed loop bore hole heat exchangers up to 500 m depth, and is probably also a preferred hole making technology for the drilling of ultradeep closed loop heat exchangers for heat and power production.

In this project, the performance of Canopus’ novel directional steel shot drilling technology for drilling long horizontal side-track wells has been tested in the Hydrostatic Drilling Test Set-up in Rijswijk. The rate of penetration was found to be much faster than drilling without steel shot, the directional concept proven, and the operational parameters ensuring good hole cleaning determined.

In addition to evaluating the drilling and steering capabilities, the wellbore patterns of horizontal grids were investigated. It was found that the productivity of a typically Dutch open geothermal doublet could increase by a factor 2 to 3 by drilling multilateral structures that directional steel shot drilling is expected to be able to drill.

Webinar: Novel drilling technology to accelerate the heat transition

Want to know more about advanced drilling technology? Sign up for our webinar on 2 December 2024. Gain insights into two advanced technology developments and their pathways to market and learn how innovative drilling technologies can drive the heat transition forward.

DEPLOI the HEAT

Canopus was able to initiate a next phase in this development programme which is named DEPLOI the HEAT. This project concerned the prototype demonstration of the Directional Steel Shot Drilling Technology in the simulated down hole environment of the drill test facilities of the RCSG research centre.

Two field trials

The two field trials in the DEPLOI the HEAT project aim to showcase capabilities in two distinct environments with escalating operational complexity: one in tight limestone in Switzerland and the other in a typical Dutch hot water sandstone reservoir in the Netherlands.

Both trials are backed by comprehensive field equipment testing at TNO’s Rijswijk Centre of Sustainable Geo-energy, drilling system modelling and real-time monitoring by the University of Calgary’s Center of Excellence on Well Construction, and Well Guidance’s extensive expertise in directional drilling for geothermal energy.

These trials aim to pilot the commercial readiness of the innovative Canopus drilling technology for geothermal projects and to enhance heat production through the unique short radius, long horizontal drilling capabilities of this technology.

Get inspired

Labtour RCSG

Innovate subsurface technologies

Novel drilling technology to accelerate the heat transition

Advancing geo-energy technologies for the energy transition

Limited growth in geothermal energy production in 2023 but a record number of drilling operations