Battery Lab

The Battery Lab drives the advancement and adoption of new battery technologies, supporting its partners in accelerating the electrification of (heavy-duty) road and non-road applications forward.

Our vision

Achieving the targets of the Paris Agreement requires batteries to play a crucial role in electrifying mobility—spanning heavy-duty road applications, as well as non-road, marine, and aviation sectors—each with their own specific battery requirements. Extending battery lifespan and improving performance and safety are essential to accelerate the transition towards zero emission mobility.

The TNO Battery Lab is more than just a battery testing facility. Its true value lies in the cutting-edge research it conducts, the advanced insights it develops into testing methods, models, and algorithms, and the application of this expertise to benefit partners seeking to validate innovative battery features or bring groundbreaking concepts to market.

Industry-focused solutions

TNO combines in-depth battery application knowledge with sector-specific expertise. Leveraging extensive experience in industries such as automotive, TNO ensures the optimal match between cell types and their intended applications. By understanding specific challenges, usage profiles, and trade-offs, we guide cell technology choices based on factors like total cost of ownership, energy requirements, safety, and lifespan.

Additionally, TNO actively investigates emerging technologies to assess their potential future impact. While focusing on real-world applications, we incorporate insights into new cell chemistries through collaborations with partners conducting fundamental research. This approach allows us to evaluate and position promising cell technologies for practical use.

Application areas:

-

(Heavy duty) road transport

-

Non-road mobile machinery

-

Maritime

-

Stationary energy storage

-

Aviation

Our facilities

TNO’s state-of-the-art Battery Lab provides advanced facilities for characterising battery systems, researching battery behaviour, and deepening our understanding of battery applications. By integrating testing activities with our battery research, we continuously improve testing methods, characterisation methodologies, battery models, and algorithms to advance battery technology.

Our cutting-edge facilities enable the validation of innovative battery features in a controlled lab environment. Using hardware-in-the-loop setups, we can accelerate testing and development processes, significantly reducing time to market. Our flexible testing methodologies and algorithms simulate a wide range of charging behaviours and conditions, allowing us to accurately measure their impact on battery performance.

The Battery Lab is planning a significant expansion of its facilities to enhance its capabilities:

- Scaling up testing capacity: Increasing the capacity for ageing tests to enable simultaneous testing of multiple cell types.

- Developing advanced physics based models: Using specialised equipment to test individual cells and specific cell components in greater detail to characterise physics-based battery models.

- Expanding prototyping scope: Utilising a multitude of advanced manufacturing methods for prototype realisation, e.g. 3D printing, (tab) welding and measurement equipment.

This expansion supports comprehensive testing, characterisation and prototyping across all battery levels, enabling deeper insights and innovation.

Our portfolio

By smartly analysing battery performance in Ageing Tests, we can accurately determine the remaining lifespan of a battery in its current application and for reuse in second-life applications. These tests consider usage history, including charging behaviour during first use, to better predict how cells degrade and perform in their second lifecycle.

We cycle batteries continuously under diverse conditions to quickly understand degradation behaviour and early identify ageing patterns. This insight informs the development of aging models and supports research towards advanced testing methods.

We evaluate general battery performance across various applications by running characterisation tests and operational cycles under different conditions, like operating temperatures, charging profiles and current levels. This approach enables the development of advanced electrical, thermal, and ageing models.

This research ensures batteries can be safely integrated into applications without health or safety risks.

- Thermal runaway: Understanding what happens when a battery cell surpasses a critical point. By including EIS measurements and analysing temperature or impedance profiles we aim to predict and prevent thermal runaway situations. We analyse behaviour at the cell, module, and pack levels.

- Abuse testing: Simulating extreme conditions with tests like overheating, overcharging, nail penetration, and ballistic impact to assess battery resilience.

- Gas measurements: Measuring toxic gases released during normal operation and misuse scenarios, such as overcharging or overheating.

- Safety markers: Developing methods and models that detect abnormalities in cell behaviour to signal issues well ahead of critical events.

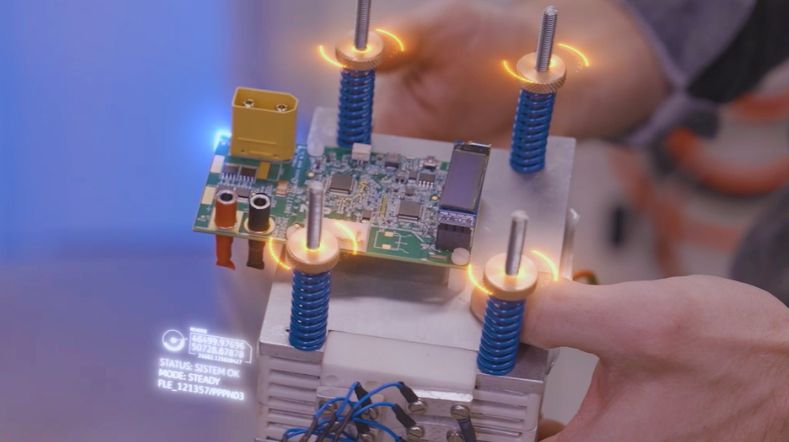

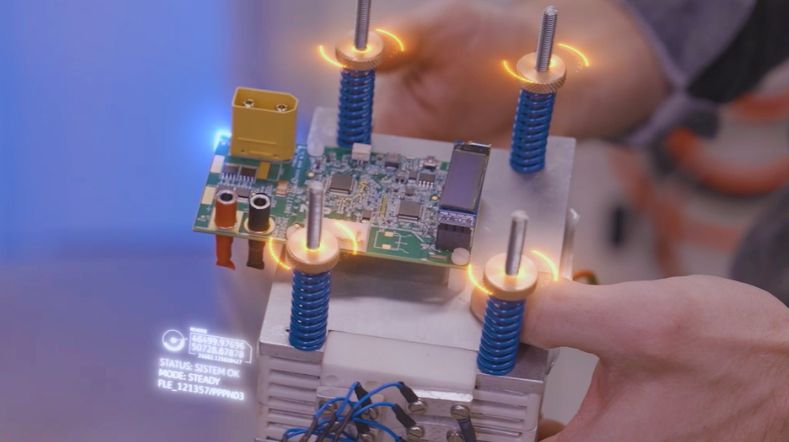

With the establishment of a prototyping facility, TNO is able to easily design and assemble battery modules and packs. This enables quick demonstrations and validation of methods, algorithms, and systems, offering a streamlined way to showcase innovations to the market. The facility allows us to test new materials (e.g., thermal buffers), advanced cooling concepts, and novel sensors, highlighting their advantages. Additionally, we can directly integrate and evaluate innovations and concepts from partners, demonstrating their practical value in real-world applications.

Let’s collaborate

TNO is looking for partners who want to leverage our expertise on developing and testing next-generation battery systems for road, non-road mobile machinery, maritime, energy storage or aviation applications.

Get inspired

How far can you travel in an electric car?

National Growth Fund invests in Dutch battery consortium for heavy duty transport

TNO opens test cell for sustainable marine engines

Battery technology: 4 developments according to the Battery Lab

Fuel cells crucial for decarbonising heavy-duty transport and non-road machinery