Hitachi SEM-S-3700N-Variable Pressure

- Category:

- Analysis equipment

- Brand:

- Hitachi

- Type:

- S-3700N

Description

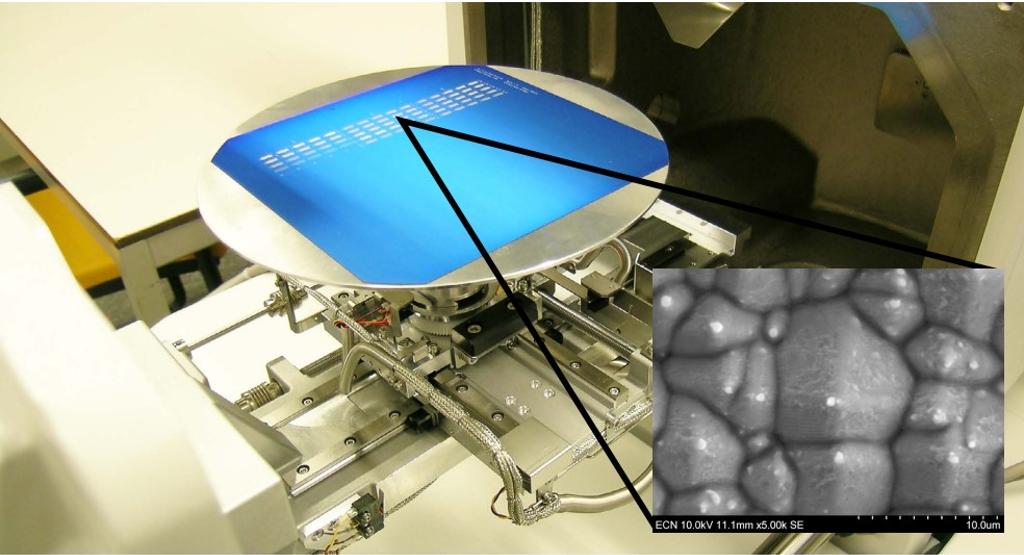

The Hitachi S-3700N Scanning Electron Microscope (SEM) a variable pressure SEM (VP) that can be operated under both high vacuum and nitrogen partial pressure up to 270Pa (0.1Atm). The SEM is equipped with an Oxford AZtec EDS analysis system. The SEM has a very large vacuum chamber, so that even large samples or a large number of (smaller) samples can be examined simultaneously.

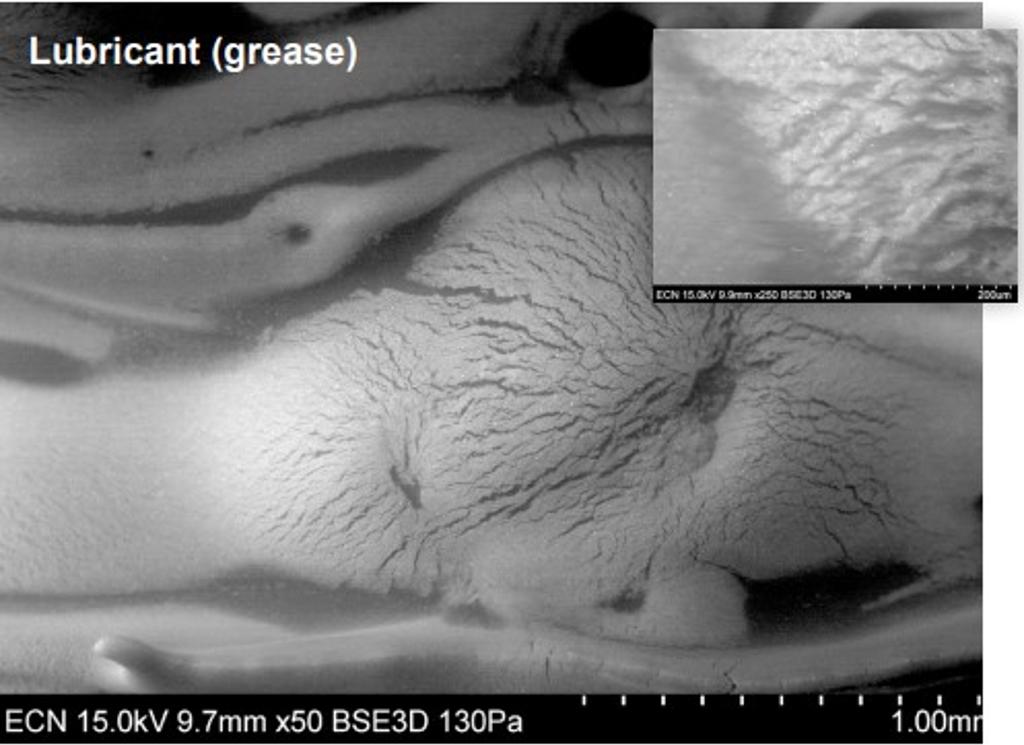

Thanks to its ability to work under partial pressure, samples no longer need to be pretreated with a conductive coating. The SEM is therefore ideally suited for examination of non-conductive materials. Contaminated samples, e.g. with (wet) corrosion products or grease and oil do not need to be cleaned beforehand. This is an important plus point, especially for damage research.

Test material can also be characterised, after which the test can be continued. No cleaning or coating is required.

Because of the EDS (Energy Dispersive Spectral Element Analysis) system, the chemical composition of materials or depositions can be determined.

Technical details

Tungsten filament

Resolution up to 10nm at 30kV under high vacuum and ideal samples

Optimal signal-to-noise ratios at 1kV, 5kV, 10kV, 15kV and 30kV

Maximum sample size to be examined up to 200mm diameter and 110mm height

Maximum sample size: 300mm diameter and 110mm high

5-axis stage, tilt -20°/+90°

Maximum weight: 5kg

Oxford AZtec EDS analysis system.

Automated element analysis

line scans

X-ray element mapping

High vacuum and nitrogen partial pressure up to 270Pa

Suitable for all materials (metals, plastics, ceramics, composites) also highly porous materials.

Additional techniques

EDS, Energy Dispersive Spectral Analysis

PMI

Suitable for insitu testing

Applications

This electron microscope is very suitable for the following applications:

Failure analysis

Large samples and possibly contaminated samples

Corrosion survey

Ash testing e.g. for biomass gasification

Solar cell technology

Membrane technology

Combustion technology

Energy technology and transition

Automated particle analysis

Chemical analysis of all types of materials without pretreatment (quantitatively from sodium, Na, qualitatively from B to Na)

Alternative to XRF with higher accuracy

PMI, Positive Material Identification