Ion Milling System

- Category:

- To be determined

- Brand:

- Hitachi

- Type:

- IN4000

Description

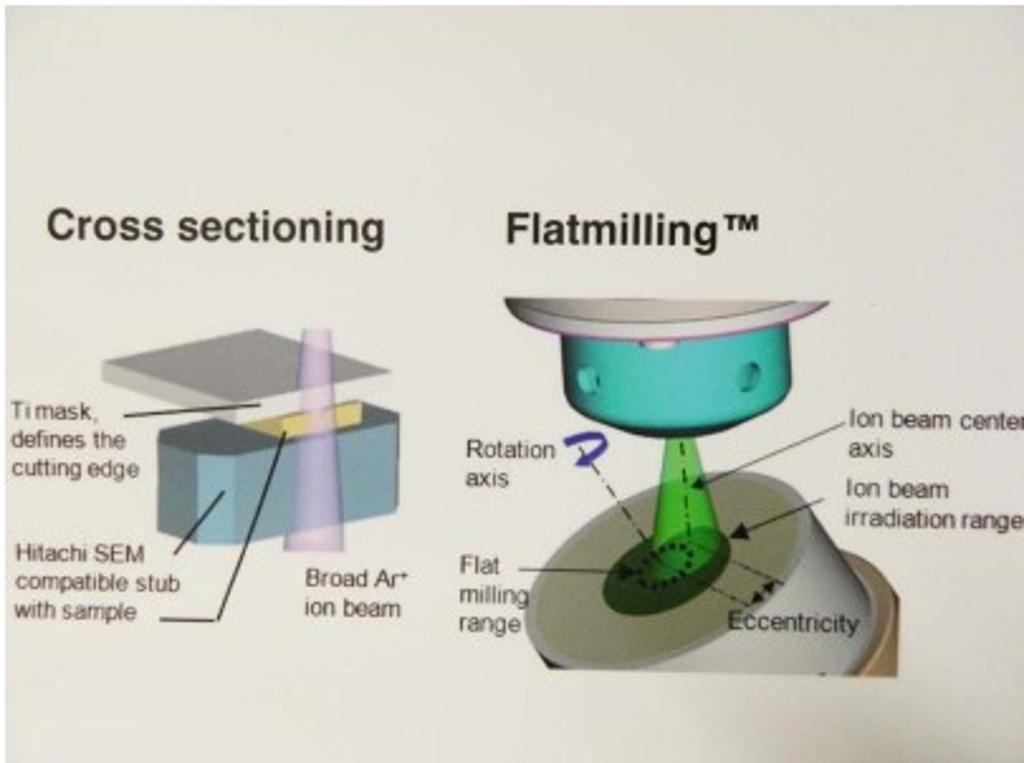

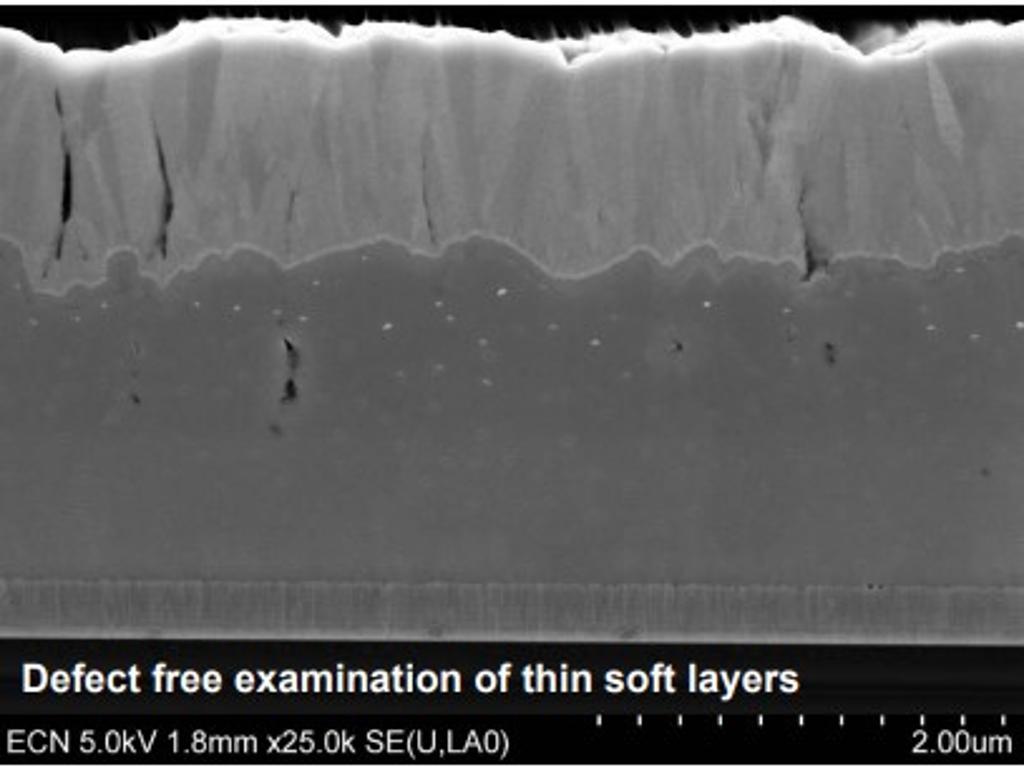

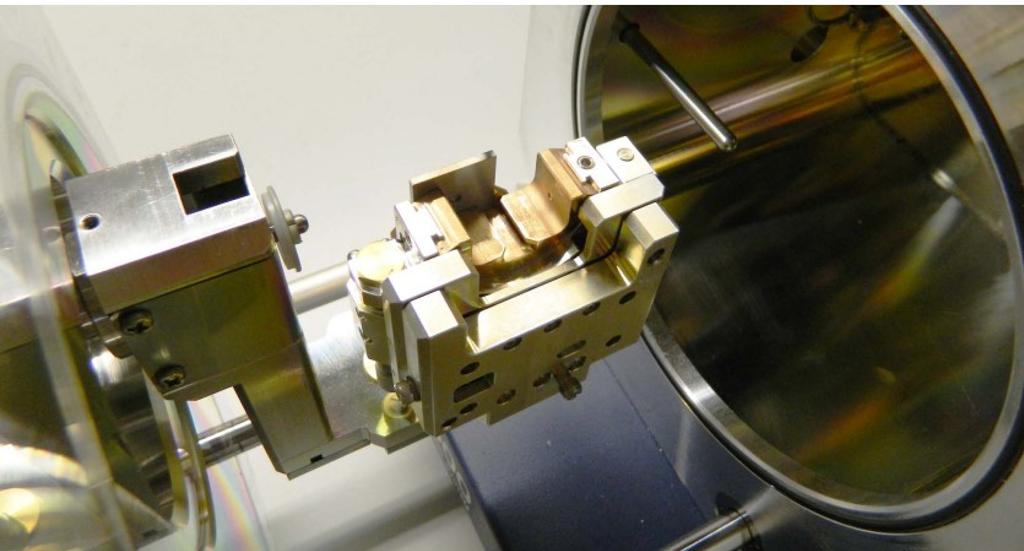

An Ar plasma beam is used to create cross sections of thin sections or layers, typically up to 500µm. The thickness is limited from economic and machining time considerations. During machining, a deformation-free surface is created. Ideally suited for research on cross sections of thin layers (from 2-3nm). Think of atomic layer deposition (ALD). Surfaces of cross-sections can also be polished (flat milling) where several nano-metres of material is removed. Suitable for making deformation-free surfaces for e.g. EBSD (Electron Beam Scattering Diffraction) analysis.

The machined surface is heated to about 80°C. This may somewhat limit the application on heat-sensitive materials.

Technical details

Sample dimensions: LxWxH - 20x10x5 mm

Section width: 1-2mm

Processing time depending on sample material and thickness: 10 min to 2 hours

Positioning: standard down to 10µm, possible down to 1µm.

Maximum sample surface temperature approx. 80°C

Cross-sectioning and surface polishing of metallographic sections

Materials: all. Limitations for heat-sensitive materials

Additional techniques

Scanning electron microscopy

EDS and WDS element analysis

EBSD: crystallographic characterisation using Electron Beam Scattering Diffraction

Applications

Cross sections of thin layers (starting at about 2 nm)

Pre-processing for EBSD (electron Beam Scattering Diffraction) analyses

Cleaning of surfaces: removal of oxidation for examination

Removal of final mechanical deformations after metallographic preparation of cross sections

Characterisation of thin layers or materials prone to smearing during mechanical preparation