Bifacial solar panels: more energy and more applications

Bifacial solar panels capture light not only from the front of the panel but also from the back. With double-sided solar panels (PV), we increase the electricity yield by about 5 to 15%. We are developing knowledge and technology for bifacial solar panels and a complete model that predicts energy yields.

Reduce electricity costs

Bifacial solar panels can reduce electricity costs enormously. For example, PV installations or projects produce the same amount of electricity on a smaller roof area. Also, fewer PV modules and system components are needed on the same base area, which leaves more light and rainfall available for ecology, for example.

Applications of bifacial solar panels

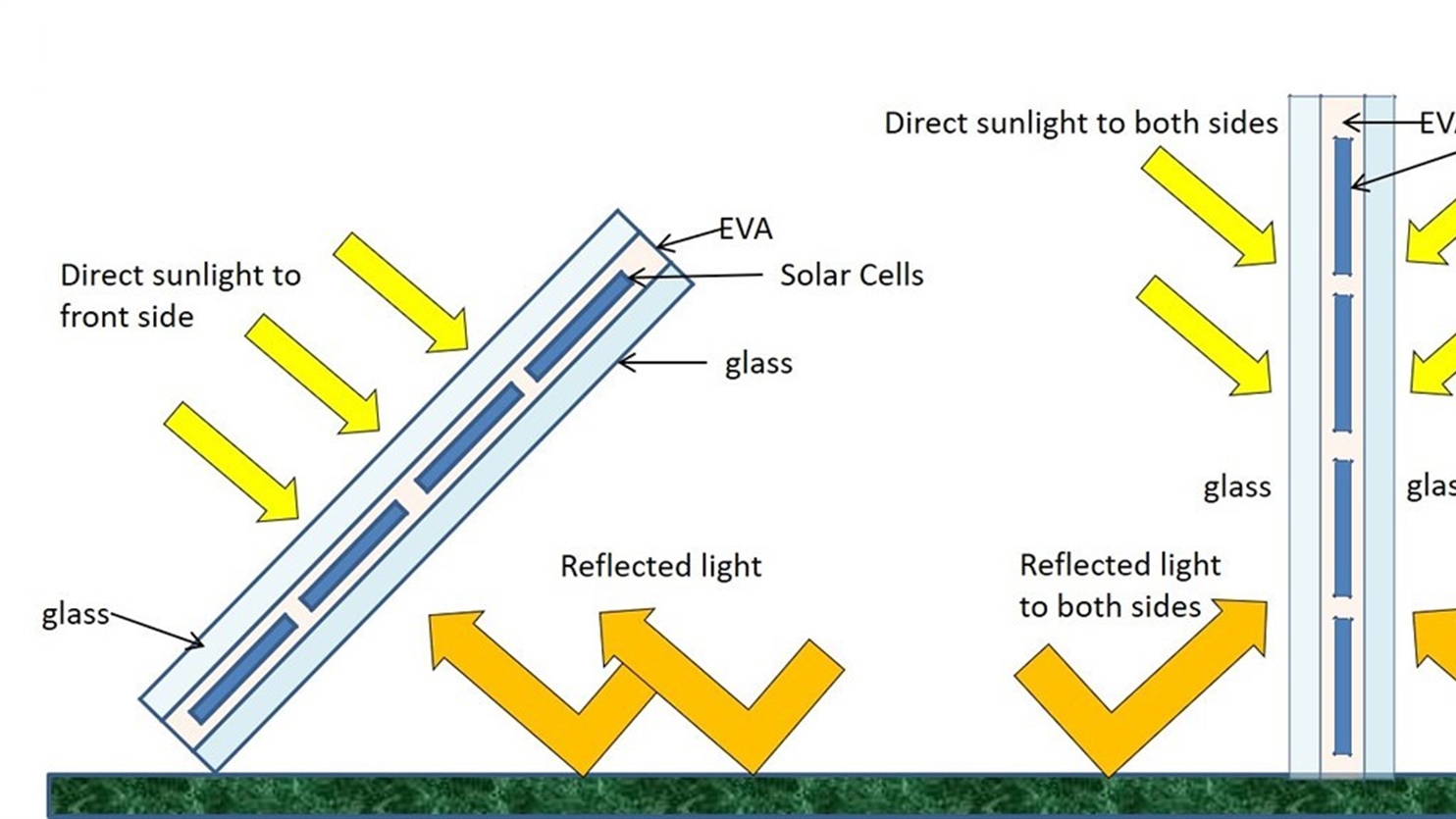

A bifacial PV panel generally consists of 120 or 144 solar cells. These solar cells have an almost identical contact pattern at the front and back, where, on both sides, more than 95% of the surface area between the metal lines is available to collect light in the solar cell.

Bifacial panels are installed in standard PV power plants, but also in emerging market segments. Think of PV integrated intobalustrades or solar windows. Or floating solar panels on open water or in combined hydro and aquaculture farms.

Another application is in combination with solar tracking systems, where you can virtually add up the additional yield of the solar tracking system and the bifacial panels. This last option also offers many possibilities to vary the irradiation under and between the panels. Ideal for agriculture or nature conservation.

Predicting energy yield with BIGEYE

We developed BIGEYE in order to make an accurate prediction of the energy yield of a PV system with bifacial modules for all parties. This is a very advanced, and as far as we know the most complete simulation model for a PV system. With BIGEYE, we can simulate the electricity output of PV systems with any configuration and at any location. With meteorological and environmental data, we calculate the electricity production per hour, day, month or year.

For PV installers, project developers, and system owners, it is very valuable to have a precise energy generation profile. This allows them to provide optimal connections to the local, national, and global electricity grid. In addition, BIGEYE helps to design PV systems in such a way that power generation better matches daily needs. For example, by increasing energy generation in the morning or afternoon.

Thermal model tested with digital twin

New applications of solar energy are often seen as a simple extension of standard solar parks. However, if the design of a solar park is different, the conditions for the solar panels can also change.

To investigate how different designs affect the performance of solar panels, we used a digital twin at an R&D location with nine rows of double-sided solar panels in a vertical east/west orientation.

Based on these comparisons, we deduced that the vertical PV panels operate at a lower temperature than expected for standard free-standing PV. We also demonstrated that the expected annual energy yield is 2.5% higher due to the lower operating temperature.

The insights from this research with a digital twin of a vertical PV system (pdf) help in designing better vertical PV systems and support decision-making, for example, in agriculture.

Knowledge and technology

Our experts are working on various new bifacial solar cell concepts with the aim of increasing efficiency and simultaneously reducing manufacturing costs. One of the bifacial cell concepts we have developed successfully, is an industrial version of the so-called TOPCon solar cell. This cell has special intermediate layers on the back, consisting of a very thin oxide and polysilicon layer. This structure counteracts the losses on the surface.

We developed this cell concept in collaboration with Tempress Systems, among others, under various subsidy projects and in several commercial projects. This technology has now been embraced by the industry and cell efficiencies of over 25% are being achieved in production.

In one of the latest bifacial cell concepts, the so-called heterojunction solar cell, very thin layers of amorphous silicon and metal oxides are used in the surface of the cell. These can be applied on both sides and have better quality as those in the TOPCon cell. Besides, they are much more transparent than the layers on the backside of the TOPCon cell, allowing sunlight to enter the solar cell optimally.

The bifacial performance of the solar cell can therefore be improved considerably, while production is potentially simpler and therefore cheaper. This concept is under development in the SolarNL consortium, including the company MCPV. MCPV aims to produce competitive solar cells in the Netherlands with more than 25% efficiency using this technology. This type of solar cell is also a very suitable basis for combining with perovskite-based solar cells to create bifacial so-called ‘tandem’ solar panels with even higher efficiencies, above 30%.

In the Horizon project IBC4EU, we are working on bifacial solar panels based on back-contact cells of the IBC type. A glass plate is used as a transparent backsheet on which conductive metal lines such as silver are screen-printed. The cells are placed on this glass plate using pick and place robots. The backs of the cells are electrically connected to the metal lines using conductive adhesive or low-temperature solder. The power of the solar panel after back-side illumination is 85% of the power after front-side illumination; this is called the bifaciality factor.

As a proof of concept, we have demonstrated that when making a mini-module of 4 cells, there is no loss of performance on the back side; the bifaciality factor of the mini-module remains 85%. IBC cells have the potential to achieve the highest efficiency of all silicon solar cell concepts. With this industrially applicable module technology, the applicability can be significantly increased.

2 bifacial solar modules, consisting of encapsulated solar cells between 2 glass panels. The tilted bifacial module receives direct sunlight on its front side and ground-reflected light, from the grass below the module, on its back side. The vertical bifacial modules can receive direct sunlight on either side depending on the position of the sun and will receive reflected light, from the grass below the modules, on both sides.

Get inspired

Shade screens with rollable solar foil combines energy generation with climate control in greenhouses

Dutch consortium develops manufacturing technology for perovskite solar cells

Webinar: Solar energy in Brabant - Building a sustainable future for Europe

The next generation of solar technologies

Solar panel production back to Europe